15 (22)

.

6.2.2

Blade floating

The completely new floating system allows the blade to float vertically, which makes working on uneven

surfaces considerably easier and more efficient. The blade can also float sideways, or locked as rigid.

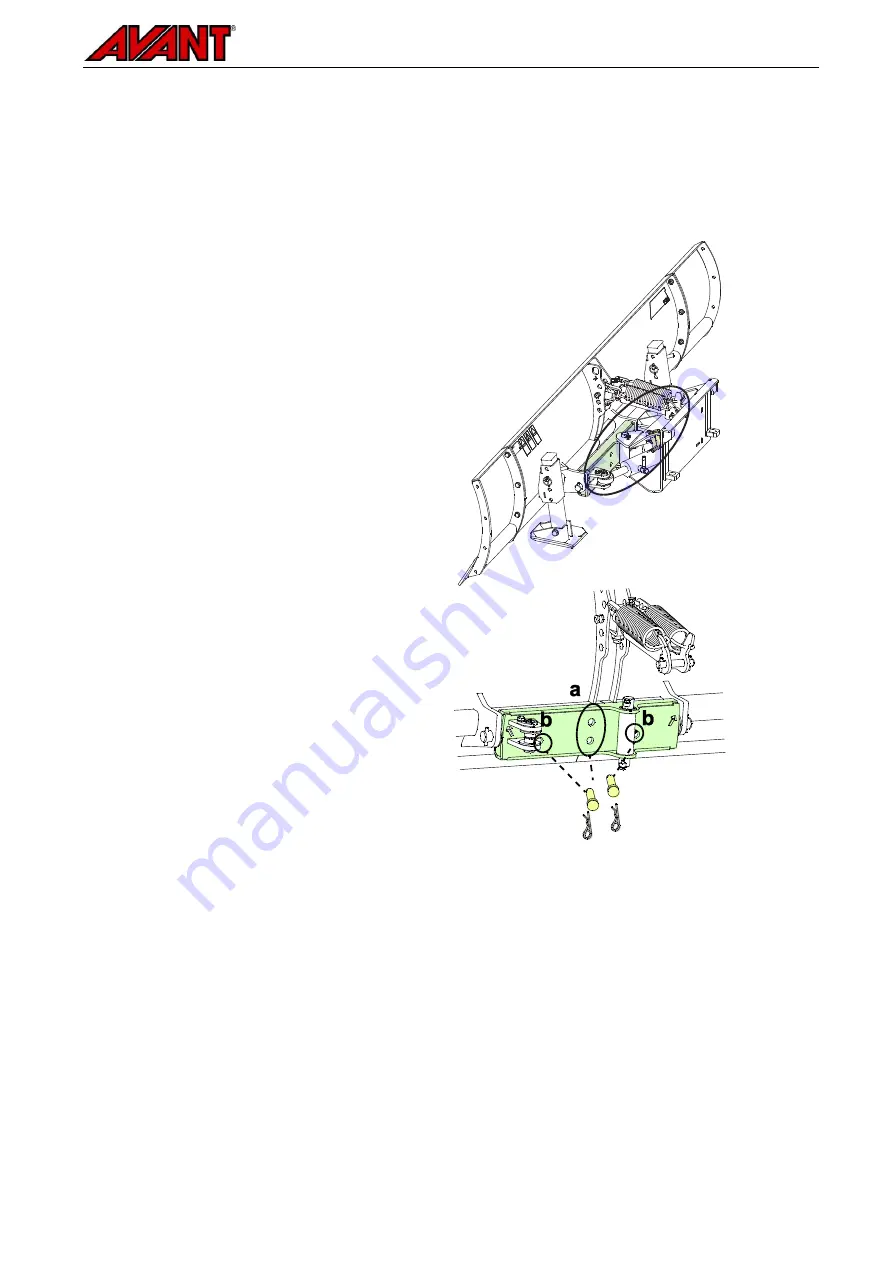

Floating is set with pins, which are stored on the frame of the attachment:

Freely floating mode:

Blade is in freely floating mode, when both pins

are not fitted, and they are stored on the frame

of the attachment.

Locked modes:

Place the pins to either locking mode, and

secure with cotter pins:

a

Sideways tilting mode

Place pins through the horizontally

aligned holes to lock the blade from

moving up and down

b

Fully locked mode

Place the pins to holes on the sides.

The blade must be against the ground,

so that the pins can be inserted.

Boom floating (optional equipment on some loader models)

If your loader is equipped with the boom floating option, it is recommended to switch it on. Floating allows the

blade to follow the surface of the ground more effectively, improving its performance.

6.3

Blade spring release system

For the safety of the operator, the blade is equipped with a spring release mechanism. When the blade edge

hits an obstacle, the blade will tilt, allowing to avoid sudden stopping of the machine. The blade moves slightly

also during normal use; if the movement is too easy, tighten or replace the springs. Grasp on chain at a time

with a secure grip by both hands and adjust the springs with care.

The blade tilts only while driving forward. When reversing with the loader the blade sections are rigid, and

therefore hitting an obstacle while reversing may lead to a sudden stop.

Summary of Contents for A36123

Page 2: ...Dozer Blade 2000 2016 1 ...

Page 22: ......