6(14)

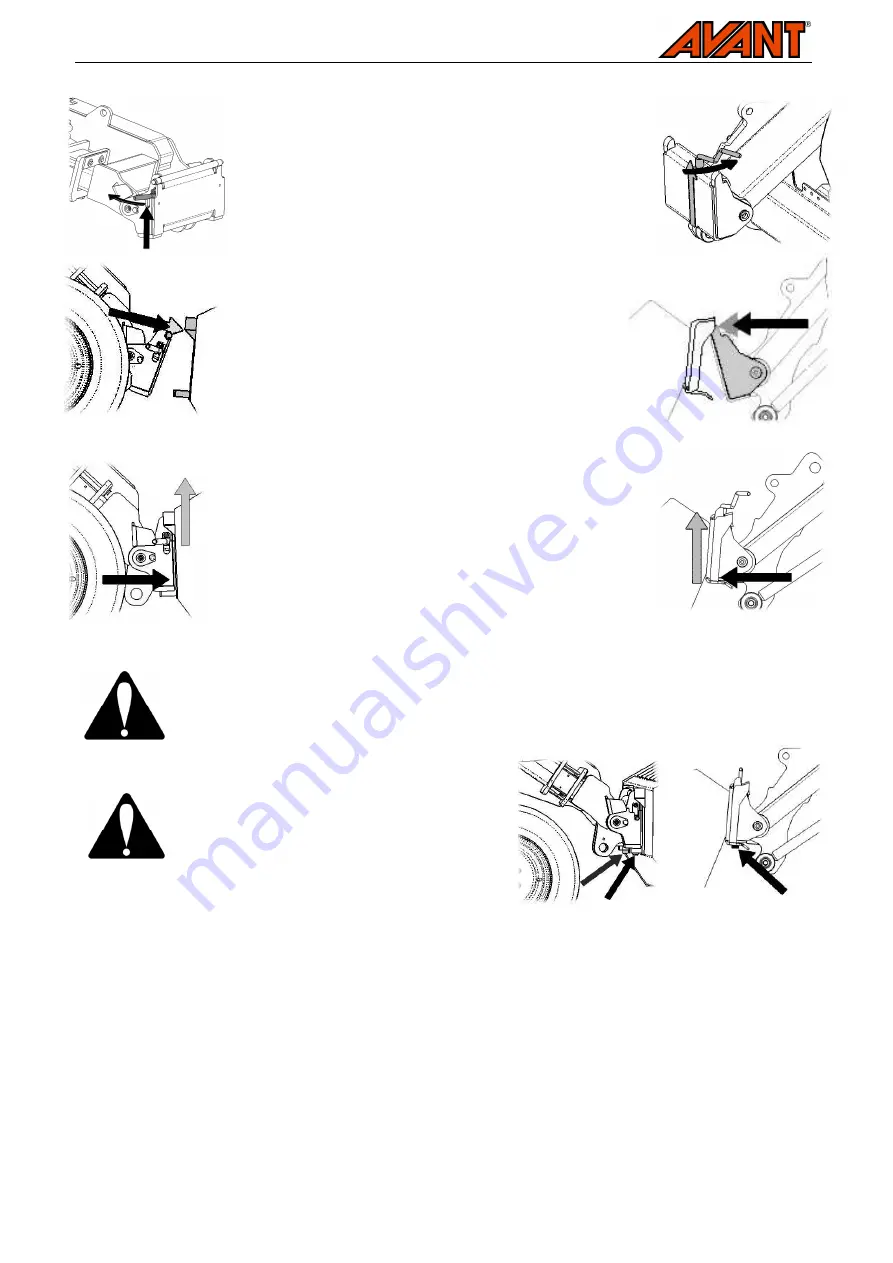

Step 1:

•

Lift the quick attach plate locking pin / locking pins

up and turn them backwards into the slot so that

they are locked in the upper position.

•

Ensure that the hydraulic hoses are not in the way

during installation.

Step 2:

•

Turn the quick attach plate hydraulically to an

obliquely forward position.

•

Drive the loader onto the attachment. If your loader

is equipped with a telescopic boom, you can utilise

this.

Step 3:

•

Lift the boom slightly – pull the boom control lever

backward to raise the attachment off the ground.

•

Turn the boom control lever left to turn the bottom

section of the quick attach plate onto the

attachment.

•

Lock the locking pins manually as you connect

the hydraulic fittings.

Do not use the automatic return of the locking pins with the log splitter. Because the

attachment plate of the log splitter is at relatively high level, tilting of an unlocked

splitter increases the risk of toppling over. We recommend that you lower the log

splitter onto the ground and secure the locking manually.

Before moving or raising the attachment,

ensure that the locking pins are in the lower

position and come through the fasteners on

both sides.

5.2.

Connecting and disconnecting the hydraulic fittings

The log splitter has two hydraulic fittings, which must be connected to the corresponding fittings on the loader.

When connecting or disconnecting fittings, shut down the loader engine and move the auxiliary hydraulics

lever of the loader to its extreme positions a few times. This way, there will be no residual pressure in the

system and the fittings are easy to connect.

To connect and disconnect the fittings, move the collar at the end of the female fitting. For correct operation of

the splitter, connect the fittings with the coloured caps first, and the remaining fittings will then be fitted

correctly.

In a 200-series equipment, the hose can be connected by pushing the fitting in the counterpart. When

connecting and disconnecting the 200-series hydraulics quick couplings, you should pay attention to their