6 (32)

2. Designed purpose of use

The AVANT Snow blower 1150/1500 is an attachment that is suitable for use with AVANT multi purpose

loaders which are shown in Table 1. The Snow blower is especially suitable for use when it is preferred to

spread snow evenly to the sides of the area instead of piling it up. The two-phase snow blower is suitable also

for professional use, and it is equipped with a powerful hydraulic system with two separate hydraulic motors

for efficient operation even when handling wet and heavy snow.

As standard, the snow blower chute can be turned electrically by 260 degrees directly from the driver’s seat.

The wide adjustment range of the manual throwing height control makes it possible to control the ejection of

snow precisely as needed, either as to pile snow directly to the side of the drive path, or to spread evenly far

away. As an option, electric throwing height adjustment is also available, which can be operated only with the

optional electric attachment control switch pack of the loaders.

The Snow blower 1150/1500 is not designed for any other use than what is specified in this manual and must

not be used for any other purposes than intended.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional maintenance. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT retailer if you have additional questions about the operation or maintenance of the equipment, or if

you require spare parts or maintenance services.

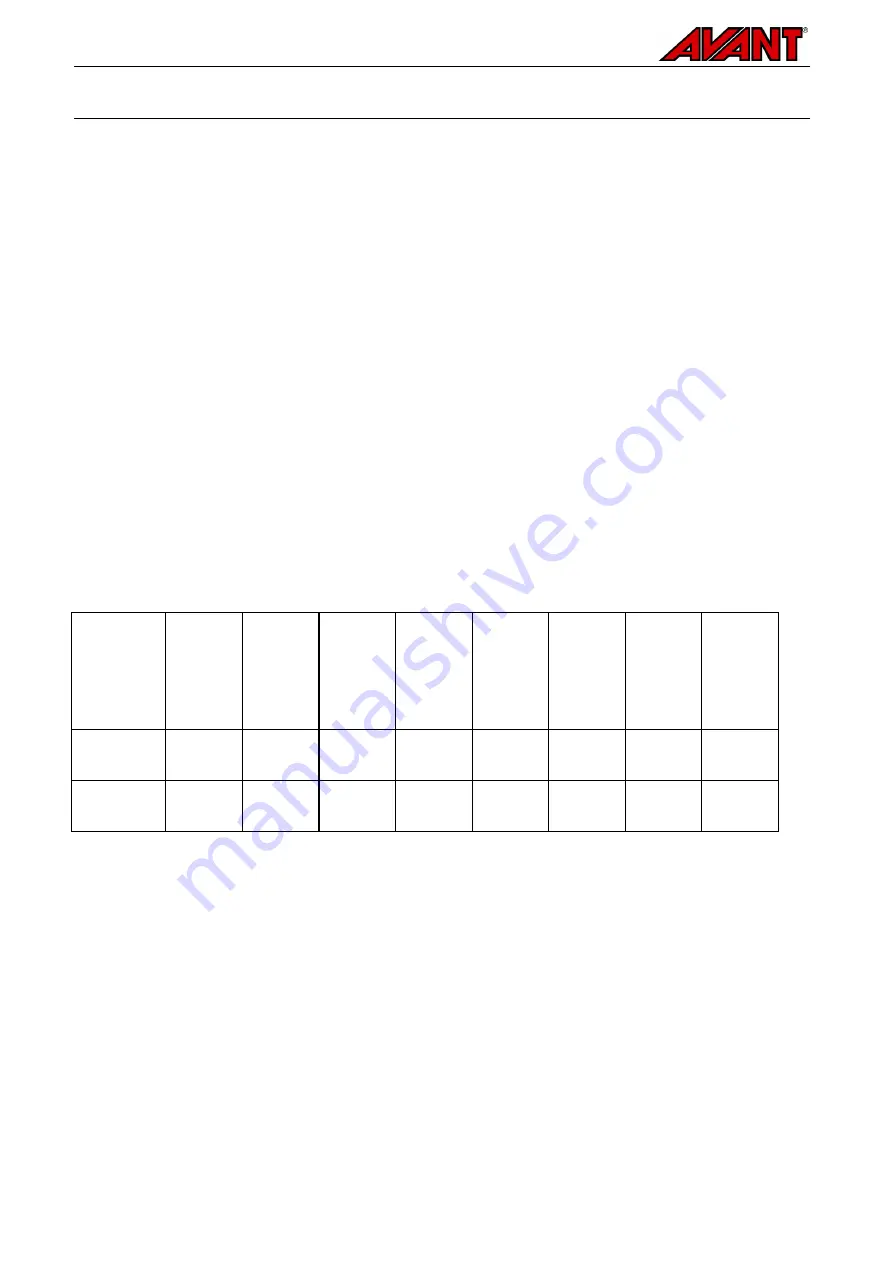

Table 1 - Snow blower 1150/1500 - Compatibility with Avant loaders

Model

220

225

225LPG

313S

320S

420

423

520

523

525LPG

528

530

R20

R28

630

R35

635

640

745

750

755i

760i

850

860i

e5

e6

A434731

(1150)

•

-

•

•

(•)

(•)

(•)

(•)

A428062

(1500)

-

-

-

-

•/(•

)*

•

•

-

It is recommended to use the attachment only with loaders marked with

•

in Table 1. When using with models

marked with (

•

), full performance may not be achieved. Additional counterweights may also be required. For

compatibility with a model not shown in table, contact your Avant dealer.

*

When using this attachment with a 600 series

loader

that

has

a <19 kW Stage V engine the performance

of this

attachment may be limited because of lower hydraulic oil output flow of the loader. Overall

performance

depends on operating conditions. Check with your dealer for more information.