19 (22)

6.2

Cleaning the attachment

Clean the attachment regularly to prevent accumulation of dirt which is more difficult to remove. A pressure

washer and mild detergent can be used for cleaning. Do not use strong solvents, and do not spray directly at

the hydraulic components, or at the labels on the attachment.

6.3

Inspection of metal structures

Also the metal structures of the attachment must be inspected regularly. Check visually for damages and

inspect the quick attach brackets and their surrounding area carefully. The attachment must not be used if it is

deformed, cracked, or torn.

Welding repairs are only allowed to be carried out by professional welders. When welding, only methods and

additives suited for steel used in attachment must be used. For more information about repairs contact your

nearest service point.

6.3.1

Tine maintenance

The condition of the tines and tine holders should be checked at least every few uses. Replace any broken

items.

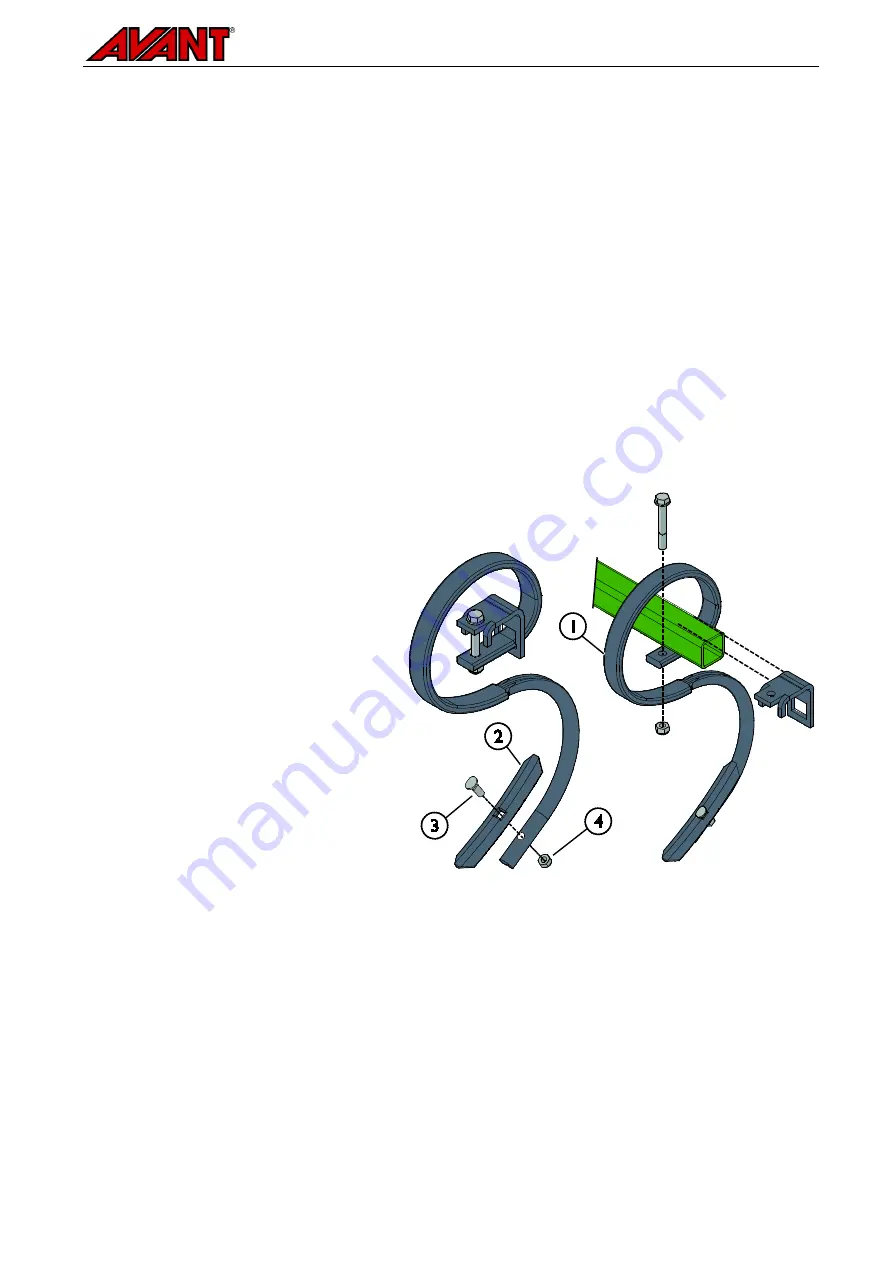

Replace the S-tine and tine head as shown in

the adjacent figures.

The S-tine kit 66150 (1) includes also the tine

head (2) and its fastening screw (3) and nut

(4).

6.4

End of life disposal

When the attachment is at the end of its useful life recycle and dispose of the attachment properly. Dismantle

the attachment and separate the different materials, such as plastic, steel, rubber, and oils, for example. Drain

and collect all oils and handle them by following the current local regulations. Never leave any oil or other

material in the environment.

Recycle each material by delivering them to a proper collecting place. Let a waste management company do

the recycling, if possible.

Summary of Contents for A442314

Page 2: ...Spring tine cultivator 2021 1 ...

Page 22: ......