Avant e6

100

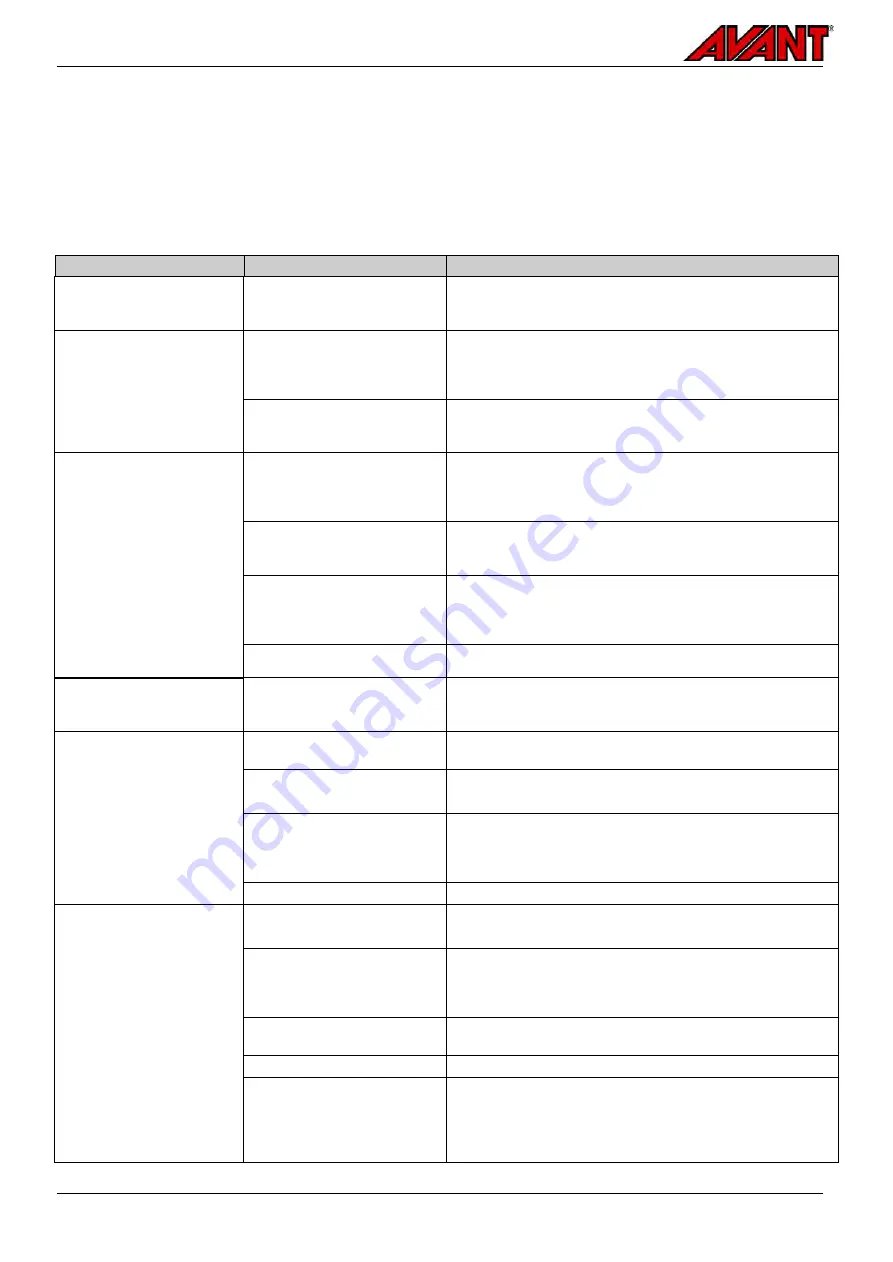

Troubleshoot

Listed below are possible causes for typical problems and suggested remedies. In case you experience trouble

with the operation of the loader, check troubleshoot lists first. If problem is not solved, contact your nearest Avant

service point or dealer.

Problem

Possible cause

Remedy

Drive pedals do not respond

Operating mode that prevents

the use of the drive pedals is

selected

Use the operating mode switch to choose a mode which allows

the use of the drive pedals. See page 55.

Electric motors won't start

when turning the ignition

switch

Driver not seated on driver's

seat

Operator must sit on driver's seat in order to use the controls of

the loader. Also, other operating mode can be selected to

operate certain attachments from another control position, see

page 55.

Ignition switch fuse blown

The ignition switch controls also the electric main switch of the

loader. There are two fuses for the ignition switch. Check all

fuses, see page 98.

Hydraulic attachment does

not work when the auxiliary

hydraulics control lever is

moved

Attachment hoses are not

coupled or the multi connector

is not fully locked

Make sure that the multi connector is properly connected.

Faulty or damaged quick

couplers (will restrict or stop oil

flow)

Replace quick couplers in multi connector.

Operator not seated on driver's

seat

Operator must sit on driver's seat to activate auxiliary

hydraulics. Also, other operating mode can be selected to

operate certain attachments from another control position, see

page 55.

Fault in attachment

Check with another attachment, if possible.

Attachment hoses will not go

into the extra front or rear

quick couplers of the loader

There is back pressure in the

auxiliary hydraulics line

Release the pressure by moving the extra auxiliary hydraulics

control lever in both directions.

Hydraulic oil overheats

Control valve not fully open

Adjust the locking plate of the aux hydraulics control lever, see

page 39.

Dirty, blocked or faulty hydraulic

oil cooler

Clean hydraulic oil cooler, check fan.

Check fan fuse, temperature switch, and relay.

Overload of hydraulic system

Allow to loader cool by leaving on idle, until hydraulic oil cooler

stops. Avoid operating an attachment at extreme load

continuously. Check that attachment is operated correctly, and

no flow restrictors are left half open on hydraulic circuit.

Low hydraulic oil level

Make sure hydraulic oil level is as shown on page 91.

Electric motors will not run

Battery is discharged or

damaged

Charge battery or start with separate battery.

Check battery condition, replace if necessary.

Operator presence control

activated

Operator must sit on driver's seat to activate auxiliary

hydraulics. Also, other operating mode can be selected to

operate certain attachments from another control position, see

page 55.

Auxiliary hydraulics control lever

is in locking position

Release the lever to neutral position.

Blown fuse

Check all fuses

Cold temperature

The current output capacity of the battery is reduced in extreme

cold. Also, hydraulic oil becomes thick (viscous) in cold.

Combined with low charge level the hydraulic motors may not

start running. Take the loader to warm place to heat, and

charge battery. Use high-quality hydraulic oil.