Service and maintenance instructions

26

R35

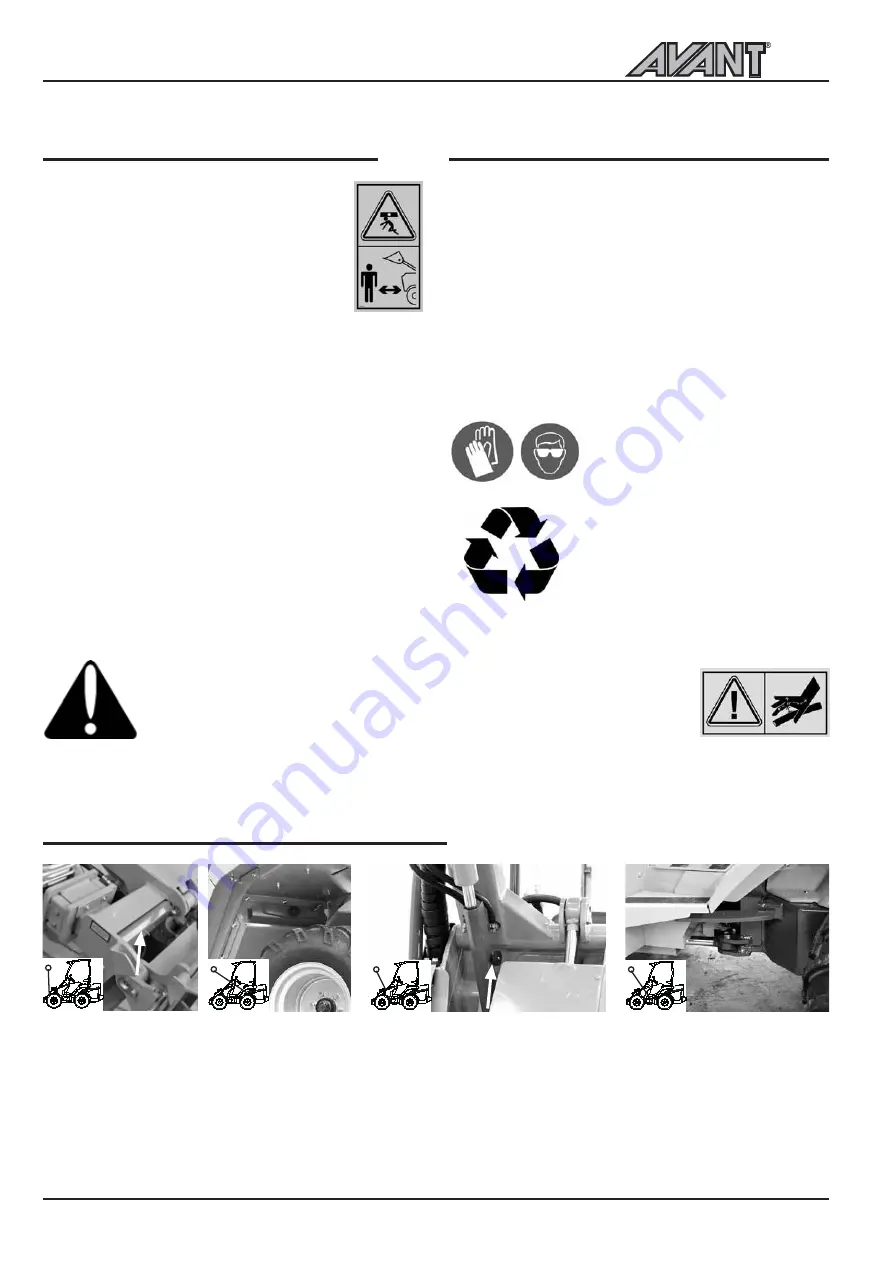

Installing of service support and frame lock

The frame can be locked with

the red frame lock. This way

the loader frame stays straight

during e.g. transportation.

Install the frame lock in the

holes on the front and rear

frame and secure it with the

cotter pin.

Make sure that the boom stays

up during maintenance operations

by putting the service support on

the lift cylinder piston rod. Secure

the service support by locking it

on the piston rod with the long

screw that is on the support.

The red service support of the boom lift

cylinder is located at the tip of the boom,

behind the attachment coupling plate. The

frame lock is located over the articulation

joint, under the seat base, and is fastened

with a bolt.

Safety instructions for maintenance

Stop the engine and let it cool down

before starting any service operation.

Put the service support on the boom lift

cylinder when working under the boom.

Install the frame lock when lifting the

machine, for instance when changing tyres

Check hydraulic hoses and components

only when the engine is stopped and hydraulic pressure

is released. Repair all leaks as soon as you have noticed

them, because a small leak can quickly change into a

big one. Do not operate the machine if you have

noticed faults or leaks in hydraulic system. Leaking

hydraulic fluid can cause serious personal injuries and

is harmful to the environment.

Check hydraulic hoses for eventual cracks and wear.

Follow the wear of the hoses and stop operation if

the outer layer of any hose has worn out. If there are

signs of oil leakage, put a piece of cardboard under

the probable leakage place in order to find the leakage.

If you find a fault, the hose or the component must

be replaced. Contact your Avant dealer or service for

spare parts.

Releasing the pressure of hydraulic system

Make sure that there isnt pressure in the hydraulic

system that could cause danger during service

operations.

In order to release the pressure in hydraulic system

stop first the engine and lower the boom down

completely. Move all control levers, including control

lever of telescopic boom and auxiliary hydraulics, to

extreme end positions a couple of times. Remember

that the boom or attachment can move when releasing

the pressure. Move the levers until all movements

have stopped.

Wear protective glasses and gloves

when servicing the machine.

The fluids in the machine are

harmful to the environment. Take

waste oil and fluids to recycling

station.

Never handle pressurized hydraulic components, because ejection of high

pressure hydraulic fluid can cause serious injuries. Do not operate the machine

if you have noticed a fault in the hydraulic system. Consult a doctor immediately

if hydraulic fluid penetrates your skin.