User Manual

6 www.AvantcoEquipment.com

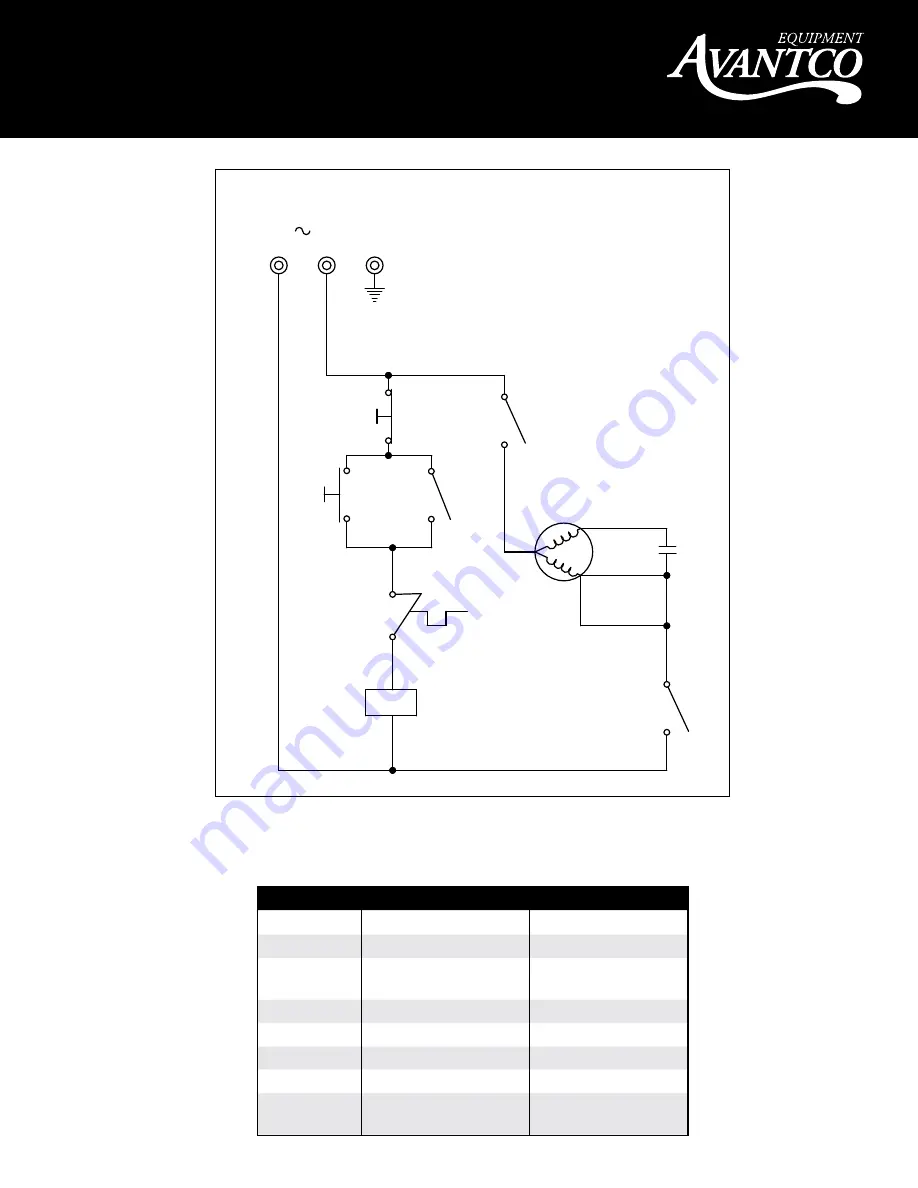

LEGEND

Description

Part Number

PB1

Push Button Stop

1-PB-SLR

PB2

Push Button Start

1-PB-SLR

T1

Oven Temp. Safety

Motor

Internally Fitted In

Motor

R1

Relay 120V

1-Rel-SLR

C1

Capacitor 20MF

1-CAP-SLR

M

Motor SL309 - 120V

1-MOT-SL309

M

Motor SL310 - 120V

1-MOT-SL310

M

Motor SL512/SL312

- 120V

1-MOT-SL512

Wiring Diagram

UNP

ACKING: Unpack the product and check for any damage incurred du

ring

transit.

This should be reported to the responsible carrier

, railway or postal

authority

, and a request for a damage report should be made

THESE INSTRUCTIONS MUST

BE FOLLOWED FOR US

TO GUARANTEE OUR FULL

SUPPOR

T OF

YOUR CLAIM

FOR PROTECTING

AGAINST

LOSS FROM CONCEALED

DAMAGE.

THE FORM FOR FILING SUCH

A

CLAIM

WILL

BE PROVIDED BY

THE CARRIER.

!

GENERAL

INST

ALLA

TION

AND OPERA

TION

INSTRUCTIONS:

INST

ALLA

TION, OPERA

TION

AND CARE OF :

SLR5009;SLR5010;SLR5012

AND SLR5312

MEA

T SLICERS

Page 1

Page 6

The

Avantco meat slicers are a range of medium duty electrically dri

ven

appliances.

They are ideal for canteens, deli’

s, caterers and sub shops.

The units have been designed to meet the highest safety and hyg

iene

standards.

The robust aluminium construction and powerful drive motor

ensure long and reliable operation and use.

1.Place the unpadded unit in the desired location with the on/o

ff switch

facing the operator

. DO NOT

plug the unit in at this point.

The supporting

table should be stable and at the correct working height.

The work surface

should be in a dry location and preferably away from passing ga

ngways.

2.IT

IS ESSENTIAL

TO STUDY

AND COMPL

Y WITH

ALL

OF

THE

SAFETY

INSTRUCTIONS DET

AILED IN

THIS MANUAL.

3 .Clean the unit with a DAMP

cloth using a neutral P

.H. dish detergent.

Wipe and dry the machine.

4.Set the thickness of slice required using the control knob ad

jacent to the

on/of

f switch.

1-CAP-SLR

C1

CAPACITOR 20mF

E

1-REL-SLR

RELAY 120V

R1

WIRING DIAGRAM

MODEL: MEAT SLICER - 120V 60Hz

MODEL CODE : SLR5009

SLR5010

SLR5012

SLR5312

LEGEND

DESCIPTION

PART NUMBER

PB1

PB2

T1

PUSH BUTTON STOP

PUSH BUTTON START

OVER TEMPERATURE SAFETY MOTOR

1-PB-SLR

1-PB-SLR

N

L

120V 60Hz

PB1

R1

R1

C1

PB2

R1

T1

WHITE

WHITE

BLUE

YELLOW

RED

BLACK

M

MOTOR SLR5009 - 120V

1-MOT-SLR5009

M

MOTOR SLR5010 - 120V

1-MOT-SLR5010

M

MOTOR SLR5012/SLR5312 - 120V

1-MOT-SLR5012

M

R1

INTERNALY FITTED IN MOTOR