Maintenance-Object Repair Procedures

555-233-143

8-1600

Issue 1 May 2002

d. This error indicates that some time slots are corrupted in the specified TDM

bus. The Minor alarm is raised when there are more than 50 bad time slots

in the bus. The aux data indicates the number of bad time slots found by

the test.

e. This error indicates that some time slots are corrupted in the specified TDM

bus. The Warning alarm is raised when there are more than 10 bad time

slots but less than or up to 50 bad ones in the bus. The aux data value

indicates the number of bad time slots found by the test.

f. This error indicates the idle time slot test found less than 10 bad time slots

in the TDM bus. The aux data value indicates the number of bad time slots

found by the test. There is no alarm associated with this error.

g. This error indicates that the daily TDM bus switch was not successful. The

active Expansion Interface (EPN) cannot talk on the bus that software was

trying to switch into. There is no alarm associated with this error.

h. These errors indicate communication problems which may be causing

message loss. TDM bus maintenance may switch the Control Channel bus

and/or Tone bus to the other bus. Test the TDM bus via the test tdm P

command and follow the procedures according to the error codes reported

from the test. The aux data value shows the Angel ID number for which a

downlink message was lost.

System Technician-Demanded Tests:

Descriptions and Error Codes

Always investigate tests in the order presented in the table below. For example,

by clearing error codes associated with the Control Channel test (#296), you may

also clear errors generated from other tests in the testing sequence.

Idle Time Slot Test on TDM bus A or B (#294)

The Idle Time Slot test detects noisy time slots on the bus and takes them

out-of-service. The Tone Detector circuit is told to listen to idle time slots and if it

detects any noise on a time slot, it returns a failure. At the end of the test, any

out-of-service time slots are retested to see if they are still noisy and restored to

service if they are idle. After every time slot has been tested, maintenance counts

the number of bad time slots and reports the number to the technician in the error

code field. No more than 220 time slots will be taken out-of-service on one bus

and no more than 300 will be taken out-of-service on both buses at one time.

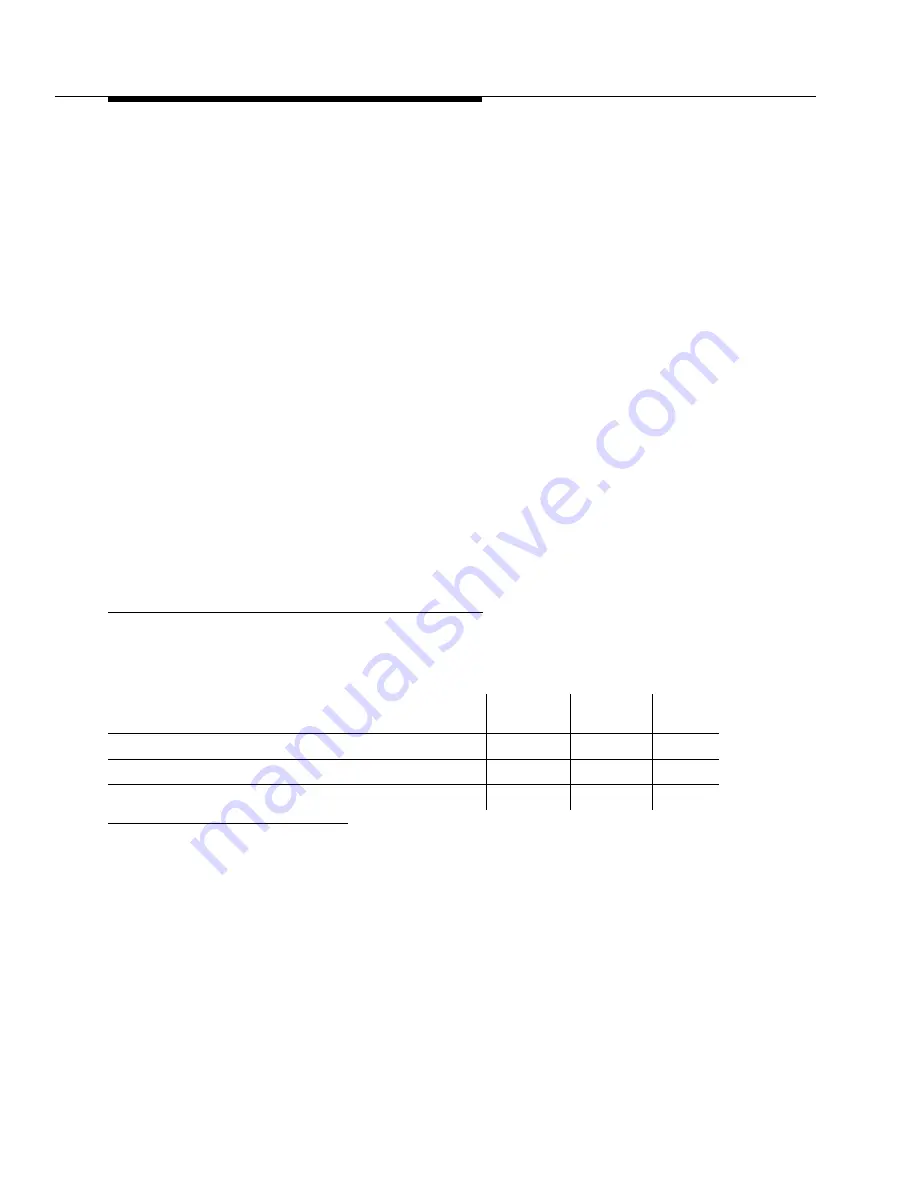

Order of Investigation

Short Test

Sequence

Long Test

Sequence

D/ND

1

1.

D = Destructive; ND = Nondestructive

Control Channel test on the Control Channel Bus (#296)

X

X

ND

Digit Detection test on the Non-Control Channel Bus (#297)

X

X

ND

Idle Time Slot test (#294)

X

X

ND

Summary of Contents for S8700 Series

Page 50: ...Maintenance Architecture 555 233 143 1 26 Issue 1 May 2002 ...

Page 74: ...Initialization and Recovery 555 233 143 3 12 Issue 1 May 2002 ...

Page 186: ...Alarms Errors and Troubleshooting 555 233 143 4 112 Issue 1 May 2002 ...

Page 232: ...Additional Maintenance Procedures 555 233 143 5 46 Issue 1 May 2002 ...

Page 635: ...status psa Issue 1 May 2002 7 379 555 233 143 status psa See status tti on page 7 406 ...

Page 722: ...Maintenance Commands 555 233 143 7 466 Issue 1 May 2002 ...