AIR PISTON ASSEMBLY

Ensure oil is drained from the tool.

Remove air cylinder

68

as described earlier.

Using external circlip pliers* free circlip

48

and drop out piston buffer

50

.

Using an Allen key* unscrew four screws

67

and separate cylinder head assembly

24

from head and handle sub-assembly

1

.

Separate air piston assembly

40

from cylinder head assembly

24

by gently tapping out handle insert

51

.

Unscrew kaylok nut

46

using a spanner* and remove from intensifier rod assembly

52

the following: piston insert

47

, external circlip

48

, piston buffer

69

, insert retaining plate

43

, gasket

65

, ‘O’ ring

71

, ‘H’ ring seal

45

, air bleed insert

44

, handle insert

51

, spiral

back up ring

42

, square seal

41

, ‘O’ ring

76

and anti extrusion ring

75

.

Remove ‘O’ ring

54

and head gasket

74

from cylinder head assembly

24

.

The intensifier rod valves are pre-set and should not be tampered with.

Assemble in reverse order to dismantling.

HEAD CYLINDER

Ensure that the head piston is in the forward position before proceeding to dismantle.

Pull off rear pin tail deflector

63

.

Release the lock on insert retainer

21

by loosening screw

2

using an Allen key*.

Using combination tool for head cylinder* unscrew and remove insert retainer

21

.

Pull out head piston

12

together with seal housing

20

. Taking care not to damage the head bores.

Pull off front pin tail deflector

15

.

Unscrew screws

16

using an Allen key* and remove head end cap

14

and wiper ring

80

.

Remove internal circlip

8

using internal circlip pliers*.

Remove retaining washer

9

, square seal

10

and spiral back up ring

11

.

Assemble in reverse order to dismantling.

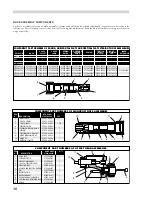

AIR VALVE SETTING

To set the air valve (tool fully assembled), unscrew front valve seat

38

and rear valve seat

31

a few turns.

Connect airline to the tool. Air should now leak through front valve seat

38

.

Using spanner (front valve seat)*, screw in front valve seat

38

until ‘O’ ring just seats and air leak ceases.

Push valve stem

35

fully back. Air should now be leaking through rear valve seat

31

.

With valve stem

35

held fully back, screw in rear valve seat

31

using spanner* until ‘O’ ring just seats and air leak ceases.

14

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

I M P O R T A N T

Check the tool against daily and weekly servicing.

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating.

Summary of Contents for 07500

Page 17: ...15 15...