A i r S u p p l y

L o a d i n g t h e To o l

C u r s o r

N o s e E q u i p m e n t

P u t t i n g i n t o S e r v i c e

6

This tool operates with compressed air at a maximum pressure of 7 bar. We recommend that you temporarily make use of the air

supply set up for your actual placing tool with precautions as described in the instruction manual for your placing tool.

I M P O R T A N T

It is essential that the correct nose equipment is fitted to the tool to ensure both effective placing of the

fastener and SAFE operation of the tool.

I M P O R T A N T

It is essential to check that the cursor orientation before attempting to operate the tool.

The procedure for loading the tool with fasteners and for fitting the nose equipment to the tool are integral. Refer to the instruction

manual for your specific placing tool EXCEPT FOR 1.6MM (1/16”) AVLUG

®

WHICH SHOULD BE LOADED ONE AT A TIME PER TEST AS

THE TEST TOOL CANNOT EXACTLY EMULATE THE 07176 PLACING TOOL USED FOR PLACING THIS FASTENER.

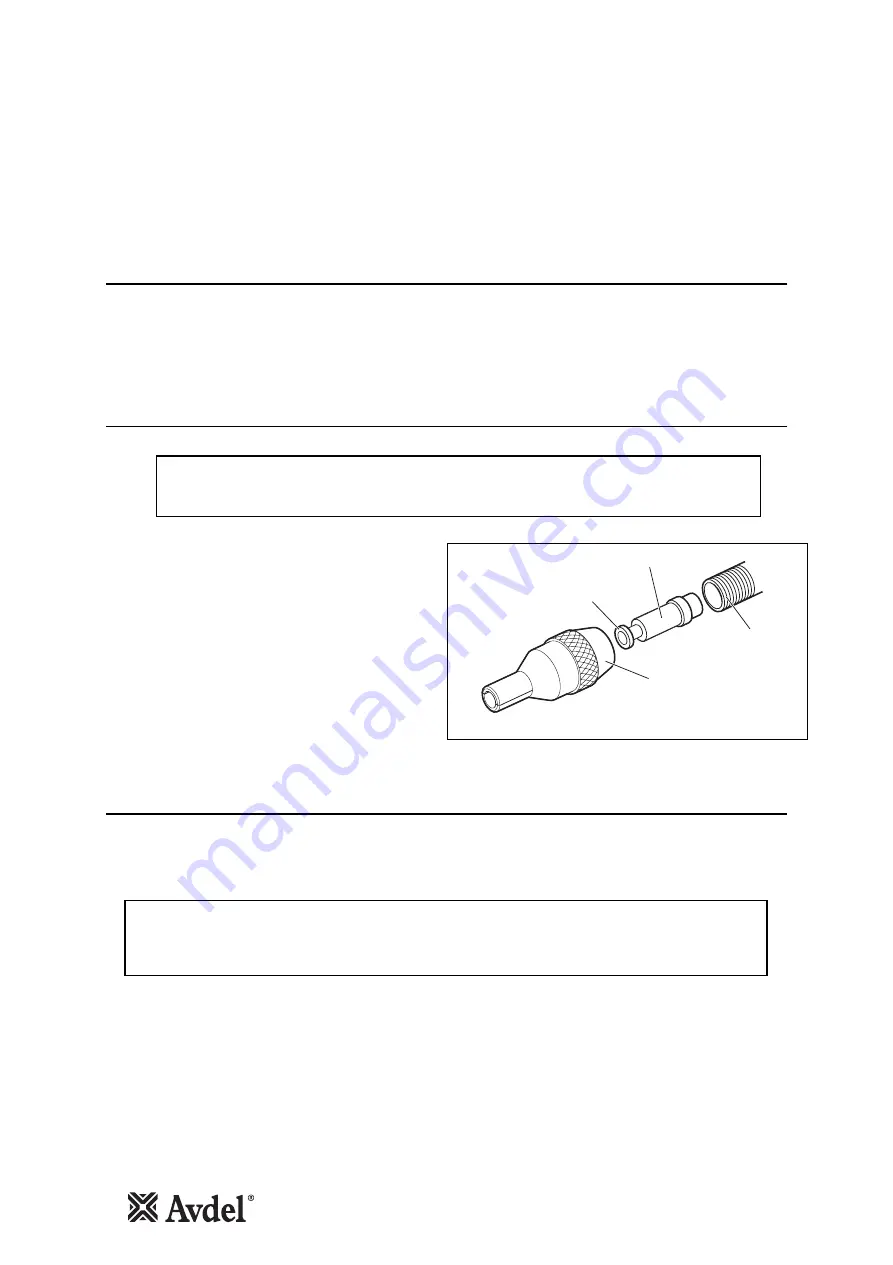

To avoid complete dismantling of the tool check the orientation

of the cursor before fitting the nose equipment to the tool. If

fitted incorrectly, the cursor will not allow feeding of the

fasteners. When fitted the correct way round, the cursor will

easily slide out of the barrel when a mandrel is pushed into its

centre then pulled back. To reverse the orientation of the

cursor, refer to the instruction manual for your particular

placing tool. The sprung loaded, slightly concave, end of the

cursor should point towards the front of the tool as shown

right.

NOSE

JAWS

TOOL

BARREL

CURSOR

SPRING

LOADED END

Fit the same mandrel, follower spring and nose jaws as you intend to fit on the tool which you have selected to place your fasteners

following the ‘tool loading’ instructions in the manual for that tool.