9

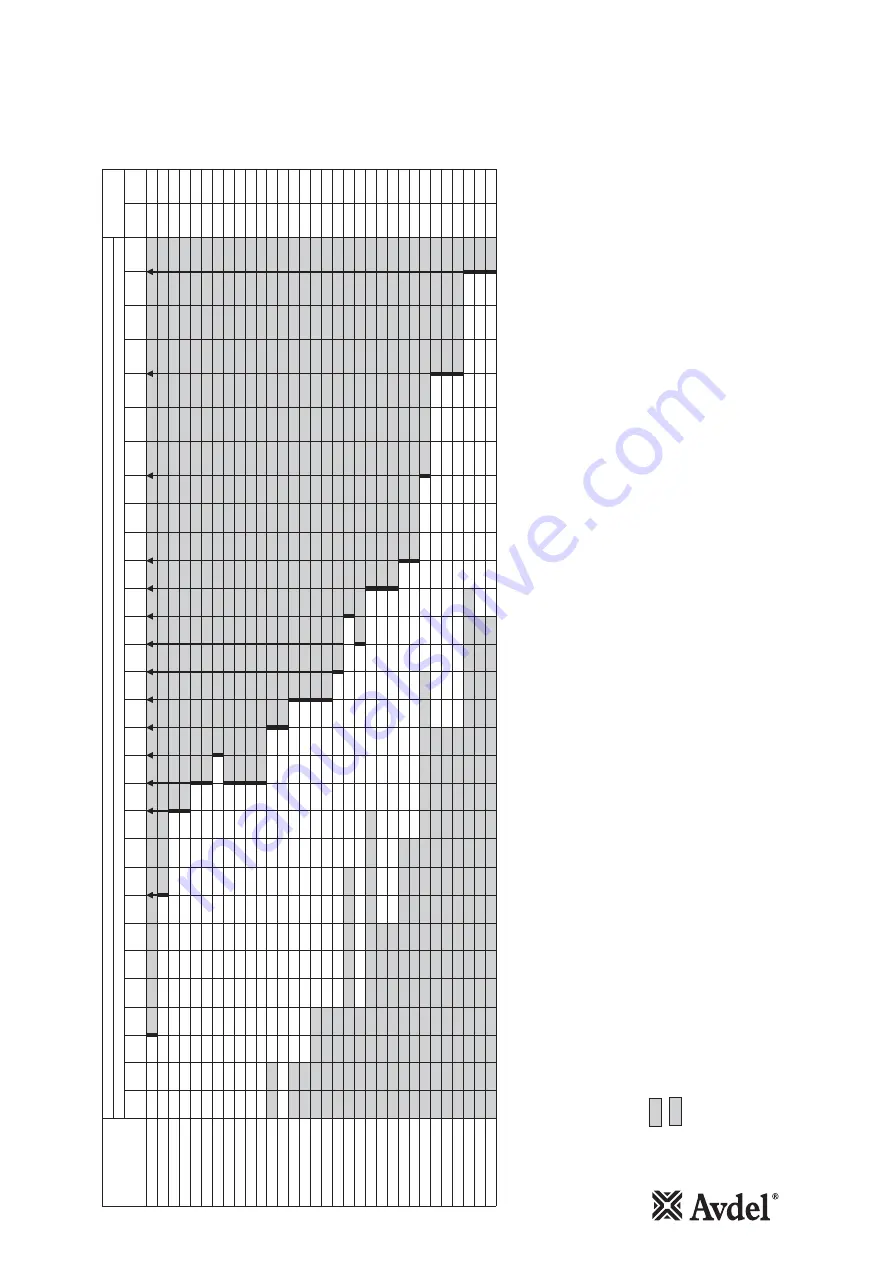

M a n d re l L i f e Ta b l e

MAXIMUM NUMBER OF F

ASTENER PLACINGS PER MANDREL

MAX. LOAD A

T

Fastener

Tool Br

oach Load (lbf / N)

5000 PLACINGS

(for which the

100 /

110 /

120 /

130 /

140 /

150 /

160 /

170 /

180 /

190 /

200 /

225 /

250 /

275 /

300 /

325 /

350 /

375 /

400 /

450 /

500 /

550 /

600

/

650 /

700 /

750 /

800 /

850 /

900 /

mandr

el is used)

445

489

538

582

627

672

717

762

806

851

896

1008

1120

1232

1344

1456

1568

1680

1792

2016

2240

2464

2688

2912

3136

3360

3584

3808

4032

lbsf

N

1/16 Avlug

26000

20000

13000

X

X

XXXX

X

XXXXXXXXXX

X

X

X

X

X

X

X

X

X

X

1

2

7

5

6

5

3/32 Briv

45700

36300

32500

28800

25100

23400

16000

10200

X

X

XXXXXXXXXX

X

X

X

X

X

XXXXX

1

7

7

7

8

7

2.8mm Rivscr

ew

50000

30500

25100

20900

16200

14600

13200

10400

8710

7240

6110

XXXXXXXXX

X

X

X

X

X

XXXXX

2

1

4

9

5

2

3mm Rivscr

ew

50000

30500

25100

20900

16200

14600

13200

10400

8710

7240

6110

XXXXXXXXX

X

X

X

X

X

XXXXX

2

1

4

9

5

2

2.5mm Avtr

onic

50000

50000

50000

49000

38900

3

5100

32400

29500

26600

23700

20400

11200

XXXXXXXX

X

X

X

X

X

X

XXXX

2

4

1

1072

# 3/32 Avlug

50000

50000

50000

50000

43200

37200

33900

31600

28800

26300

23200

14500

XXXXXXXX

X

X

X

X

X

X

XXXX

2

4

4

1085

3/32 Avlug

50000

50000

50000

50000

50000

40300

35900

33300

30900

28200

25700

18000

6920

XXXXXXX

X

X

X

X

X

X

XXXX

2

5

8

1148

3/32 Chober

t

50000

42600

33500

28200

23400

20400

17400

15000

12900

10800

9300

6400

XXXXXXXX

X

X

X

X

X

X

XXXX

2

4

2

1077

3/32 Gr

ovit

50000

42600

33500

28200

23400

20400

17400

15000

12900

10800

9300

6400

XXXXXXXX

X

X

X

X

X

XXXXX

2

4

2

1077

2.5mm Avser

t

50000

42600

33500

28200

23400

20400

17400

15000

12900

10800

9300

6400

XXXXXXXX

X

X

X

X

X

XXXXX

2

4

2

1077

4-40 UNC Avser

t

50000

42600

33500

28200

23400

20400

17400

15000

12900

10800

9300

6400

XXXXXXXX

X

X

X

X

X

XXXXX

2

4

2

1077

1/8 Avlug

--

50000

50000

50000

50000

48400

39800

3

5900

3

4500

30900

25700

19100

10800

XXXXXX

X

X

X

X

X

X

XXXX

2

9

1

1294

2.8mm Avtr

onic

50000

50000

50000

50000

50000

50000

50000

44200

38500

35500

33100

27900

21900

14600

XXXXXX

X

X

X

X

X

X

X

X

X

X

2

9

5

1312

1/8 Chober

t

--

50000

50000

41700

3

5100

29500

26000

22600

20200

18000

12200

9660

7080

5250

XXXXX

X

X

X

X

X

X

X

X

X

X

3

0

5

1357

1/8 Gr

ovit

--

50000

50000

41700

3

5100

29500

26000

22600

20200

18000

12200

9660

7080

5250

XXXXX

X

X

X

X

X

X

X

X

X

X

3

0

5

1357

3mm Avser

t

----

41700

3

5100

29500

26000

22600

20200

18000

12200

9660

7080

5250

XXXXX

X

X

X

X

X

X

XXXX

3

0

5

1357

6-32 UNC Avser

t

----

41700

3

5100

29500

26000

22600

20200

18000

12200

9660

7080

5250

XXXXX

X

X

X

X

X

X

XXXX

3

0

5

1357

1/8 Briv

----

50000

50000

50000

50000

50000

44200

38500

33100

28200

22900

16800

8510

XXXX

X

X

X

X

X

X

XXXX

3

3

8

1504

1/8 Briv (St.Steel)

----

-

----

50000

50000

41000

34600

30500

26000

20900

15700

8900

X

X

X

X

X

X

XXXXXX

3

9

0

1735

3.5mm Rivscr

ew

----

50000

50000

50000

50000

34700

30200

26600

20400

15800

12200

9550

7410

5820

X

X

X

X

X

X

X

X

X

X

X

X

X

362

1610

5/32 Briv

----

-

----

-

-

32400

25100

20200

16400

13200

10700

8710

7000

X

X

X

X

X

X

X

X

X

X

X

443

1971

4.0mm Rivscr

ew

----

-

-

-

50000

50000

50000

44200

32400

25100

20200

16400

13200

10700

8710

7000

X

X

X

X

X

X

X

X

X

X

X

443

1971

4.8mm Rivscr

ew

----

-

-

-

50000

50000

50000

44200

32400

25100

20200

16400

13200

10700

8710

7000

X

X

X

X

X

X

X

X

X

X

X

443

1971

5/32 Chober

t

----

-

----

-

48400

35100

26600

21900

17600

14500

11700

9660

7760

5190

X

X

X

X

X

X

X

X

X

X

456

2028

5/32 Gr

ovit

----

-

----

-

48400

35100

26600

21900

17600

14500

11700

9660

7760

5190

X

X

X

X

X

X

X

X

X

X

456

2028

5/32 Briv (St.Steel)

----

-

----

-

------

25100

22400

18600

13600

10500

7590

5

620

XXXXXXX

6

2

2

2767

3/16 Briv

----

-

----

-

----

50000

50000

47900

38500

32700

24300

19700

1

5500

12200

9660

7500

6100

X

X

X

X

784

3488

3/16 Chober

t

----

-

----

-

----

50000

50000

47900

38500

32700

24300

19700

1

5500

12200

9660

7500

6100

X

X

X

X

784

3488

3/16 Gr

ovit

----

-

----

-

----

50000

50000

47900

38500

32700

24300

19700

1

5500

12200

9660

7500

6100

X

X

X

X

784

3488

3/16 Briv (St.Steel)

----

-

----

-

---------

35900

2

7500

22600

18400

15000

12200

10500

8700

7000

5500

X

922

4101

6mm Briv

----

-

----

-

--------

50000

35900

2

7500

22600

18400

15000

12200

10500

8700

7000

5500

X

922

4101

1/4 Chober

t

----

-

----

-

--------

50000

35900

2

7500

22600

18400

15000

12200

10500

8700

7000

5500

X

922

4101

TO CONVERT THE BROACH LOAD INTO A MAXIMUM OF F

A

STENERS PLACINGS PER MANDREL

•

•

•

Locate your br

oach load r

eading on the scale at the top of the table and on the left-hand side, find the line with your fastene

r (name & size).

The maximum r

ecommended number of fastener placings with one mandr

el will be shown wher

e they intersect. THIS NUMBER OF PLACING

S MUST NOT BE EXCEEDED.

In case of doubt contact Avdel UK Limited

Wher

e the achieved br

oach load is in between two values on the scale at the top of the table, use the higher table value to det

ermine the mandr

el life

Note

•

•

•

# Denotes using long mandr

el

3/16 Briv

, 6mm Briv & 1/4 Chober

t - At higher br

oach loads, tool air pr

essur

e may need to be Cir

ca 90PSI

Any application which r

esults in a br

oach load in excess of that stated for a mandr

el life of 5000 rivet placings

(Refer to right hand column of table) should be r

e

ferr

ed to Avdel UK Limited.

X

Br

oach Load is too high - If close to the lowest number of placings, contact Avdel UK Limited for advice

Never use mandr

els to place mor

e than 50000 placings or mor

e than the highest number shown

-