12

Servicing the Tool

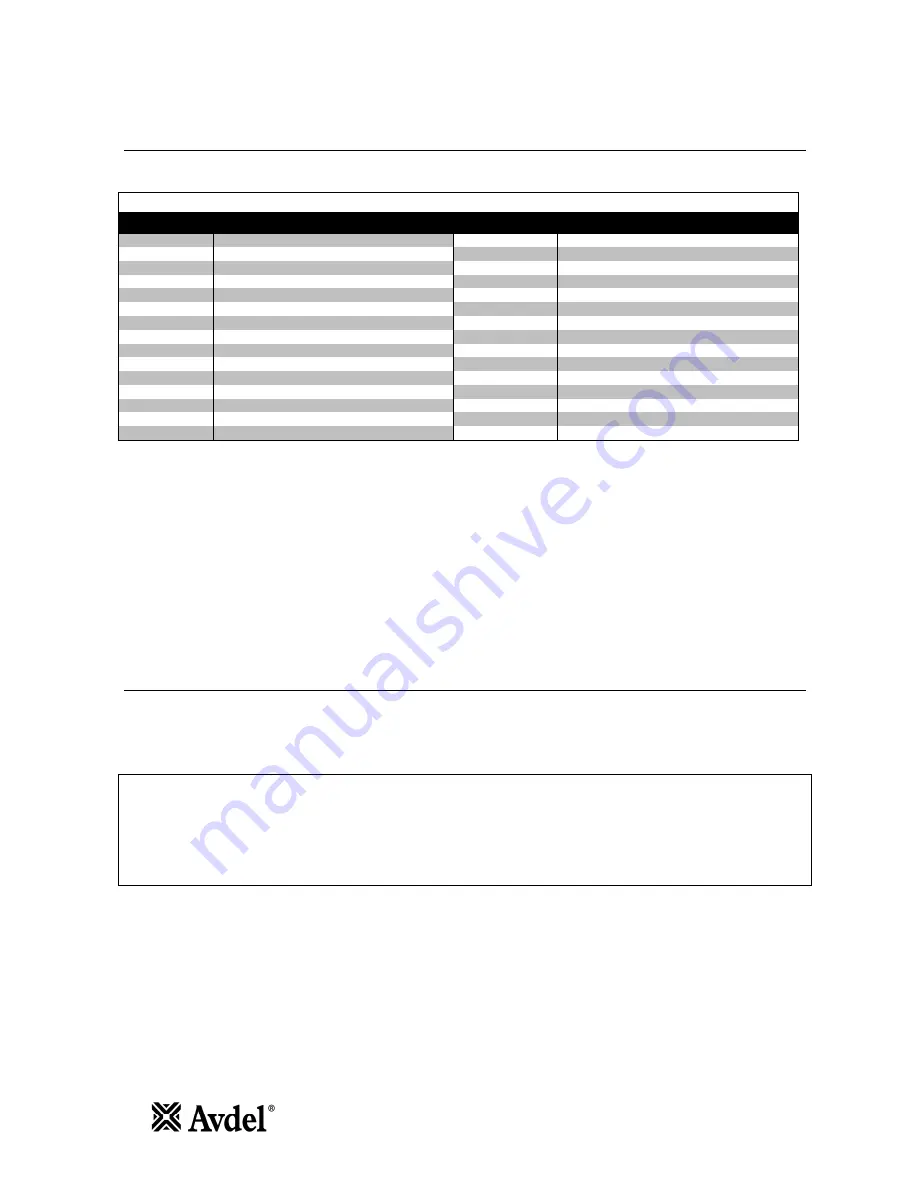

Service Kit

For all servicing we recommend the use of the 73200 Service Kit.

SERVICE KIT : 73200-99990

PART NO.

DESCRIPTION

PART NO.

DESCRIPTION

07900-01040

AIR PISTON ROD BULLET

07900-01054

SEAL HOUSING PUSH ROD

07900-01041

BASE PLATE EXTRACTOR

07900-01055

SEAL RETAINER WRENCH

07900-01042

HANDLE RETAINING NUT WRENCH

07900-00427

SLIDING OFFSET HANDLE

07900-00043

HEAD PISTON BULLET

07900-00151

T HANDLE EXTENSION

07900-01043

HEAD PISTON FRONT SEAL SLEEVE

07900-00692

TRIGGER VALVE EXTRACTOR

07900-01044

HEAD PISTON REAR SEAL SLEEVE

07900-00158

2mm PIN PUNCH

07900-01045

HEAD PISTON SEAL GUIDE

07992-00020

GREASE – MOLYLITHIUM EP 3753

07900-01046

HEAD VICE JAW

07992-00075

GREASE – MOLYKOTE® 55M

07900-01047

LIP SEAL HOUSING PUSH ROD

07900-00755

GREASE – MOLYKOTE® 111

07900-01048

LIP SEAL HOUSING SLEEVE

07900-00756

LOCTITE® 243 THREAD LOCK

07900-01049

LOCKNUT SOCKET

07900-01060 *

PRIMING SYRINGE (x2)

07900-01050

REAR LIP SEAL GUIDE

07900-01061 *

PULL STROKE SETTER

07900-01051

REAR LIP SEAL PLUNGER

07900-01062 *

RETURN STROKE SETTER

07900-01052

REAR PISTON BULLET

07900-01063 *

PRIMING SYRINGE EXTENSION

07900-01053

RETURN PISTON EXTRACTOR

07900-01066

STARTER NUT

* Priming Kit 73200-99991 also includes these parts and can be supplied separately.

For servicing the following standard tools are needed (not supplied with Service Kit).

•

4mm Allen key

•

5mm Allen key

•

6mm Allen key

•

10mm Allen key

•

14mm Spanner

•

22mm Spanner or Socket

•

27mm Spanner

•

48mm Spanner

•

10mm PTFE Tape

Spanners and Allen keys are specified across flats unless otherwise stated.

Maintenance

Annually or every 500,000 cycles (whichever is sooner) the tool should be completely dismantled and new components should be used where

worn, damaged or when recommended. All 'O' rings and seals should be renewed and lubricated with Molykote® 55m for pneumatic sealing or

Molykote® 111 for hydraulic sealing.

I M P O R T A N T

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

The airline must be disconnected before any servicing or dismantling is attempted, unless specifically instructed otherwise.

It is recommended that any dismantling operation be carried out in clean conditions.

Prior to dismantling the tool it is necessary to remove the nose equipment. For fitting and servicing instructions see page 8.

For a complete service of the tool, we advise that you proceed with dismantling of sub-assemblies in the order shown.

After any dismantling remember to prime the tool.