CLUTCH

Place tool handle and bush assembly

1

in vice fitted with soft jaws.

Unscrew clutch housing

35

(left hand thread) and remove bush

38

from clutch housing.

Withdraw clutch assembly, taking care not to bend push rod

30

.

Pull out push rod (long)

30

.

Remove tool from vice and gently tap on front end of assembly to remove needle roller

59

and push rod (short)

64

.

Holding square drive end of clutch spindle

43

, unscrew adjustment nut

28

.

Pull off adjustment lock washer

29

and spring

41

.

Depress spring

41

and remove pin

31

.

Remove collar

40

and three balls

39

.

Split retaining ring halves

32

.

Move front jaw

34

relative to clutch spindle

43

until small hole in side of front jaw

34

is aligned with track of balls

37

in clutch spindle

43

.

Ten balls

37

will become visible through small hole in front jaw

34

.

Gently tap front jaw

34

, allowing ten balls to fall out of hole in front jaw

34

(as each ball is ejected, turn front jaw

34

on clutch spindle

43

to align next ball with hole).

Insert small rod through centre of front jaw

34

and tap out clutch spindle

43

.

Remove drive jaw

33

, key

36

and spring

41

.

Clean and inspect components, renewing any worn or damaged items, paying special attention to condition of front jaw

34

and drive jaw

33

.

Assemble in reverse order to dismantling.

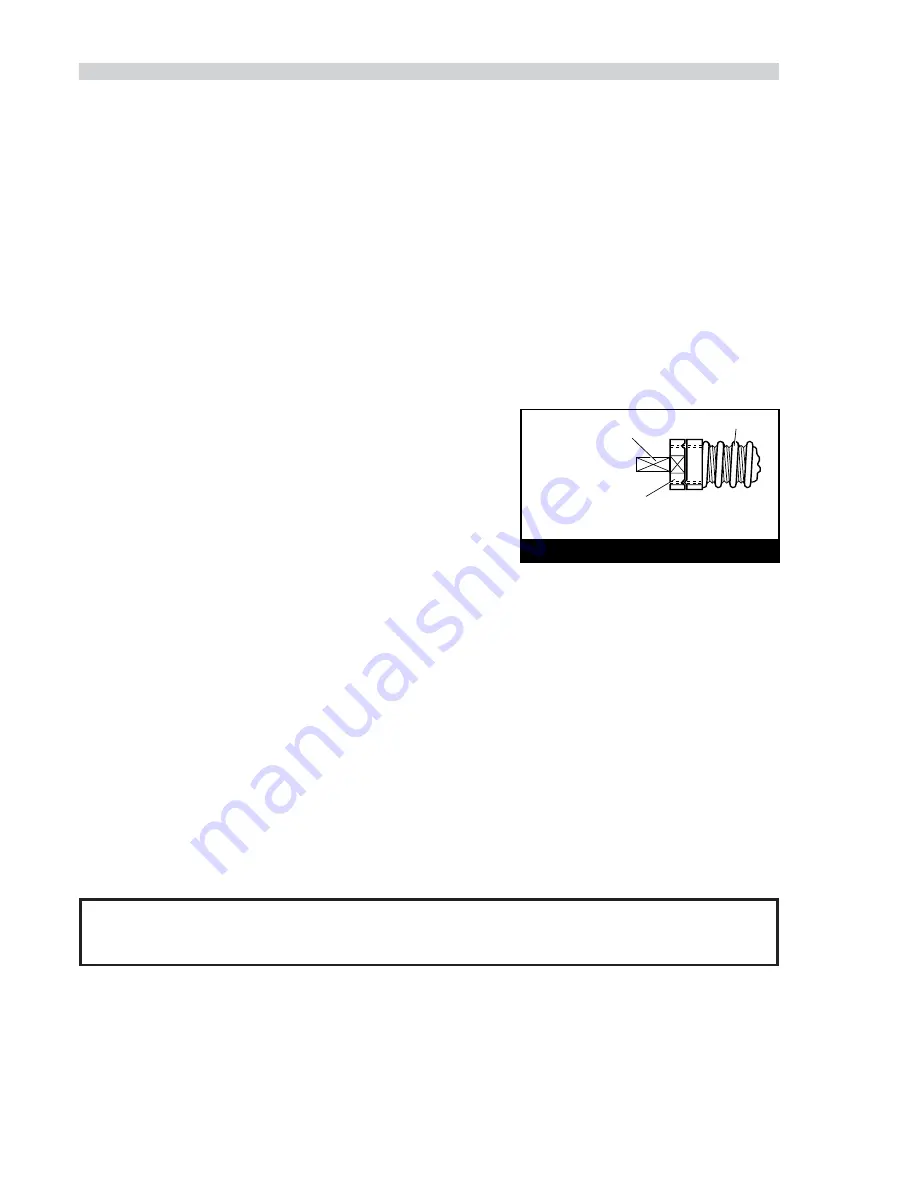

Reset clutch torque (dependant on clutch spring fitted : see page 7 ) in the

following manner (see diagram)

Place square drive on end of clutch spindle

43

in vice, engaging approximately

10mm in vice jaws. This allows for spanner entry.

Using a spanner, unscrew adjustment nut

28

until it is level with the end of the

thread of the clutch spindle. Torque can then be increased / decreased as dictated

by the fastener type and size by turning the adjustment nut clockwise/anticlockwise

as appropriate.

12

HANDLE ASSEMBLY

Replace handle and bush assembly

1

in soft jaw vice.

Using spanner on ring gear

44

, remove front remove front gear assembly.

Using spanner on housing

26

, remove inner gear assembly.

Remove ‘O’ ring

19

and spacer

18

from handle and bush assembly

1

and pull out motor assembly. (It may be necessary to tap the front

end of handle and bush assembly

1

on a wooden block until motor assembly slides out).

Unscrew silencer retainer assembly

9

and remove perforated washer

10

, silencer body

12

and silencer element

11

.

Unscrew nipple

8

from adaptor

7

.

Unscrew adaptor

7

from handle and bush assembly

1

and remove filter

6

.

Tap out pin

15

and carefully pull out trigger assembly, (take care not to damage ‘O’ rings).

Support trigger

17

and carefully drive out pin

16

taking care not to damage or bend valve

3

.

Separate trigger

17

from valve

3

and remove ‘O’ ring

14

, three ‘O’ rings

2

from valve body

13

and ‘O’ rings

4

&

5

from valve

3

.

Unscrew knob

75

and remove ‘O’ ring

67

from handle and bush assembly

1

.

Remove screw

73

and washer

74

.

Lightly tap end plate

70

to break Loctite seal between end plate

70

and valve assembly

65

.

Remove end plate

70

, taking care not to damage pins

72

.

Remove ‘O’ ring

71

and spring

69

.

Push valve assembly

65

out of handle and bush assembly

1

.

I M P O R T A N T

Valve assembly 65 is a manufacturer supplied assembly and MUST NOT be dismantled.

Remove ‘O’ ring

66

from valve assembly

65

.

Remove ‘O’ ring

68

from valve bush but do not attempt to remove valve bushing from handle and bush assembly

1

.

Assemble in reverse order to dismantling.

When replacing screw

73

and washer

74

ensure thread sealant is used on screw threads.

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

ADJUSTMENT NUT SET

LEVEL WITH FACE AT END

OF THREAD ON CLUTCH SPINDLE

SQUARE DRIVE ON END

OF CLUTCH SPINDLE

CLUTCH SPRING

RESETTING CLUTCH TORQUE