6

P

U T T I N G I N T O S E R V I C E

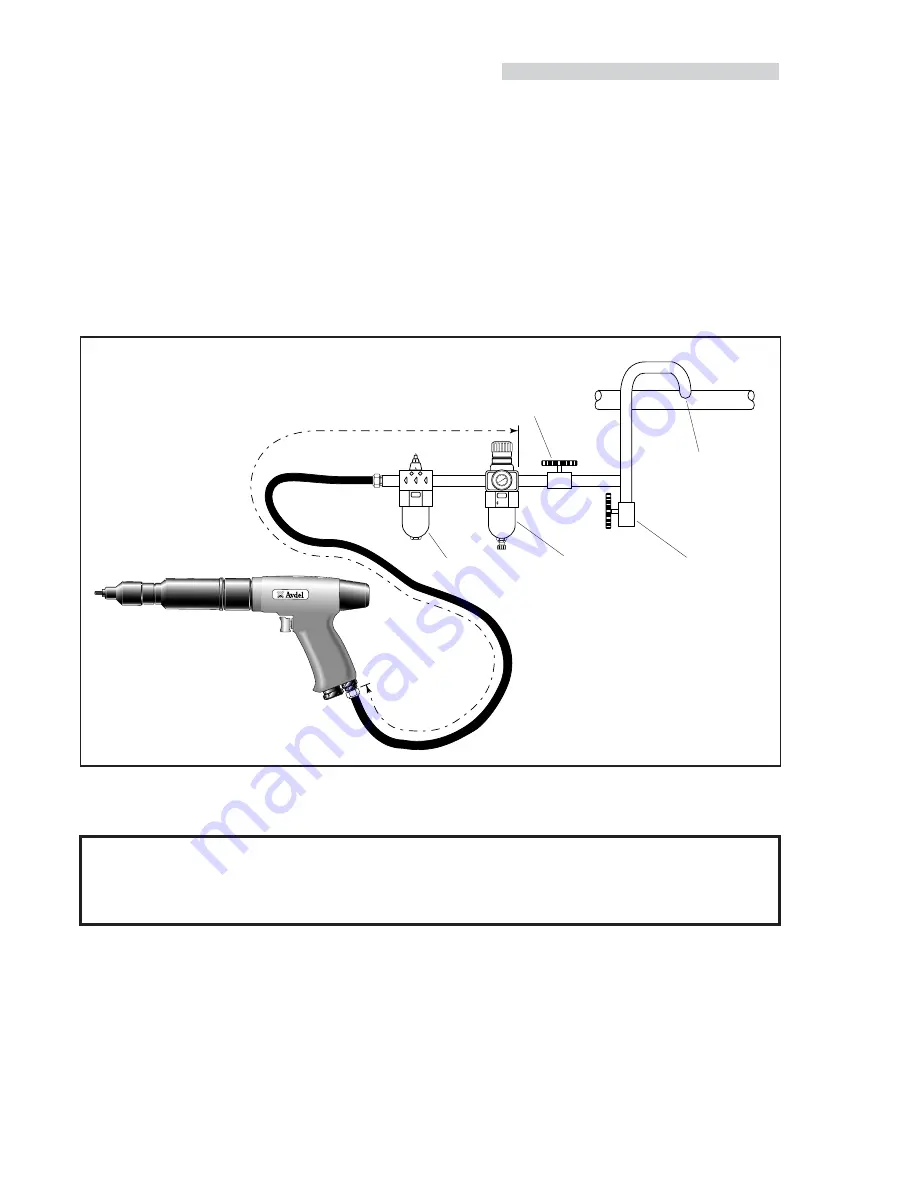

A I R S U P P L Y

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

automatic oiling/filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure

maximum tool life and minimum tool maintenance.

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system

or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/

4

inch.

Read servicing daily details page 10.

8

6

4

2

0

10

12

14

16

TAKE OFF POINT

FROM MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

LUBRICATOR

3 METRES MAXIMUM

OPTION 1

Ensure that the correct nose equipment is fitted.

Connect the tool to the air supply.

Place the insert into the prepared hole of the application.

Locate the drive screw of the tool into the insert.

Depress the trigger. The drive screw will screw into and

collapse the insert, and then automatically reverse out.

OPTION 2

Ensure that the correct nose equipment is fitted.

Connect the tool to the air supply.

Screw the insert lip first onto the drive screw of the tool.

With the insert on the tool, locate it into the prepared hole of

the application

Depress the trigger. The drive screw will screw into and

collapse the insert, and then automatically reverse out.

O P E R A T I N G P R O C E D U R E

I M P O R T A N T

When placing Standard Nutserts, lubricate the drive screw of the tool every 25 placings. This is best acheived by wiping

the drive screw with a sponge soaked with STP Lubricant part number 07992-00013

■

■

■

■

■

■

■

■

■

■