16

Assemble in reverse order to dismantling noting the following points:

•

Place lip seal

8

onto the insertion rod* ensuring correct orientation. Push the guide tube* into the head of the tool and push the

insertion rod* with the seal into place through the guide tube*. Pull the insertion rod* out then the guide tube.

•

Drop seal retainer

30

against lip seal

8

large flange first.

•

Fit seals

11

and

13

onto the piston.

•

Lubricate the cylinder bore and place the piston sleeve* into the back of head assembly

4

. Slide the bullet* onto the threaded part

of piston

7

and push the piston with the seals through the piston sleeve* as far as it will go. Slide the bullet* off the piston and

remove the piston sleeve.

•

Fit seal housing

5

and lip seal

67

.

•

Tighten jaw spreader housing

1

fully tightened onto head piston

7

BEFORE tightening locknut

3

against it.

•

Use Loctite 932 when reassembling Retaining Nut

26

.

•

Remove ‘ON/OFF’ valve assembly

60

.

•

Clamp the body of the inverted tool

ACROSS THE AIR INLET BOSSES

in a vice fitted with soft jaws.

•

Pull off rubber boot

80

.

•

Using the peg spanner* unscrew base cover

40

.

•

Unscrew locknuts

76

(2 off) and remove base plate

77

.

•

Remove liner

45

together with sealing washers

75

(2 off) and 'O' rings

78

(2 off).

•

Remove pneumatic piston assembly

42

together with ‘O’ ring

39

, lip seal

41

(3 off) and guide ring

35

.

Assemble in reverse order.

•

Remove pneumatic piston assembly

42

and seal assembly

34

as described immediately above.

•

Using the ‘T’ spanner* and ‘T’ spanner spigot* undo clamp nut

36

and remove it together with clamp plate

63

, transfer tube

assembly

44

, ‘O’ ring

6

, valve rod

43

and silencer pads

62

.

•

Release the tool from the vice and separate body

38

with ‘O’ ring

31

from handle assembly

32

.

•

Remove ‘O’ ring

33

from the intensifier tube and pull off head assembly

4

from handle assembly

32

.

•

Push out valve seat

64

with both ‘O’ rings

6

.

•

Pull out all the components of valve spool assembly

54

.

•

Finally remove ‘O’ ring

59

out of the handle counterbore.

Assemble in reverse order noting the following points -

•

Ensure that the central port in valve seat

64

faces upwards.

•

Use Loctite 243 when reassembling Clamp Nut

36

, torque to 11ft lb (14.91 Nm).

•

Using the 2 millimetre diameter pin punch*, drive trigger pin

48

out and lift off trigger

47

.

•

Unscrew trigger valve

46

using the trigger valve extractor*.

Assemble in reverse order to dismantling.

I M P O R T A N T

Check the tool against daily and weekly servicing

Priming is ALWAYS necessary after the too has been dismantled and prior to operating.

* Item included in the G4 service kit. For complete list see page 15.

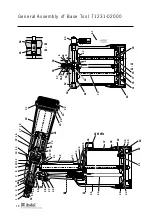

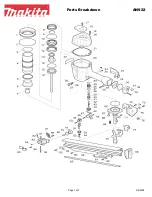

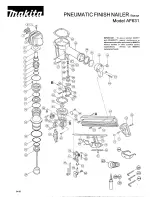

Item numbers in

bold

refer to the general assembly drawing and parts list on pages 18-19.

Servicing the Tool

Head Assembly

Pneumatic Piston Assembly

Valve Spool Assembly

Trigger

Summary of Contents for Genesis G4 HD

Page 2: ......

Page 17: ...17 English Notes...

Page 24: ......

Page 39: ...39 Fran ais Notes...

Page 46: ......

Page 61: ...61 Deutsch Anmerkungen...

Page 68: ......

Page 83: ...83 Italiano Notes...

Page 90: ......

Page 92: ......