EN-1320

OPERATION AND INSTALLATION MANUAL

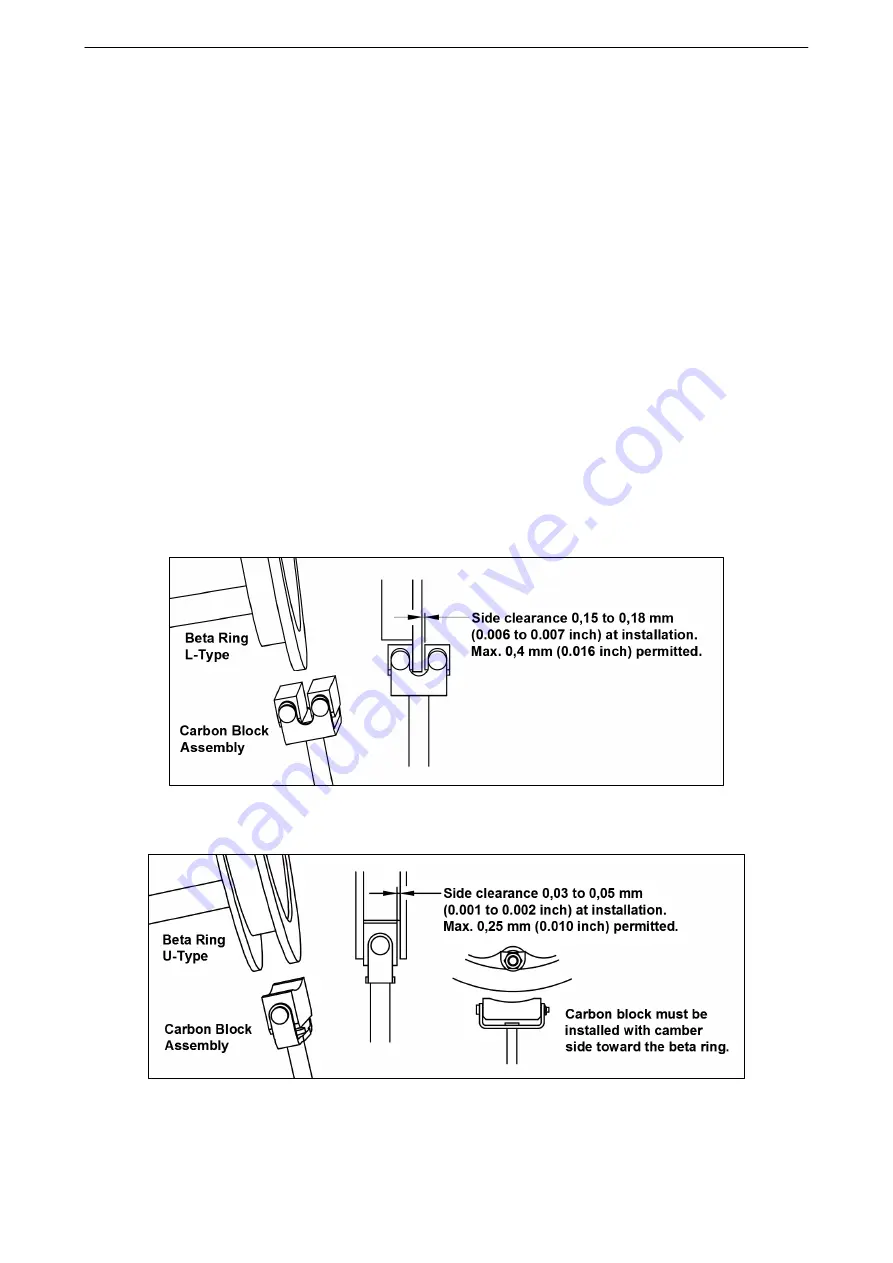

2) Fit the carbon block into the U-Type beta ring with side clearance 0,025 to 0,05 mm

(0.001 to 0.002 inch) at new installation. Maximum clearance 0,25 mm (0.01 inch) is

acceptable. Evenly sand the sides of carbon block with 600-grit sandpaper to achieve

required clearance, as necessary. The block must be installed with camber edge toward

the beta ring. See Figure 5-14.

c) Check free movement of the carbon block in the beta ring throughout full 360 degrees of

propeller rotation, noticing any binding.

CAUTION 1: POSITIVE RADIAL CLEARANCE MUST EXIST BETWEEN THE CARBON

BLOCK AND THE BETA RING OVER THE ENTIRE TRAVEL RANGE OF THE

BETA RING. OTHERWISE DAMAGE OF THE CARBON BLOCK AND THE

BETA RING WILL OCCUR. THE AIRFRAME OR ENGINE MANUFACTURER’S

MANUAL MAY INCLUDE ADDITIONAL INFORMATION AND REQUIREMENTS.

CAUTION 2: MAKE SURE THAT ANY METAL PART OF THE CARBON BLOCK ASSEMBLY

IS NOT TOUCHING THE BETA RING. OTHERWISE DAMAGE OF THE

CARBON BLOCK AND THE BETA RING WILL OCCUR.

CAUTION 3: MAKE SURE THAT A VISIBLE CLEARANCE EXIST BETWEEN THE FEEDBACK

LEVER AND THE SLIP RING (IF APPLICABLE) THROUGHOUT 360 DEGREES

OF ROTATION. OTHERWISE DAMAGE OF THE FEEDBACK LEVER AND THE

SLIP RING WILL OCCUR.

FIGURE 5-13

FIGURE 5-14

61-10-20

INSTALLATION AND OPERATION INSTRUCTION

Page 5-11

2017-10-06