Puma 13.5

Owner’s Manual

RIGGING

Colour Coding.

Avian rigging wires are colour coded so that you can check the approximate that age of the wire. The wires

have a small coloured patch on one of the ferrules sealed in with heat shrink protection. If they heat shrink is

missing the wire should be replaced immediately. (The heat shrink provides support to the wire where it

emerges from the ferrule to reduce flexibility and thus reduce wear in this most vulnerable area.)

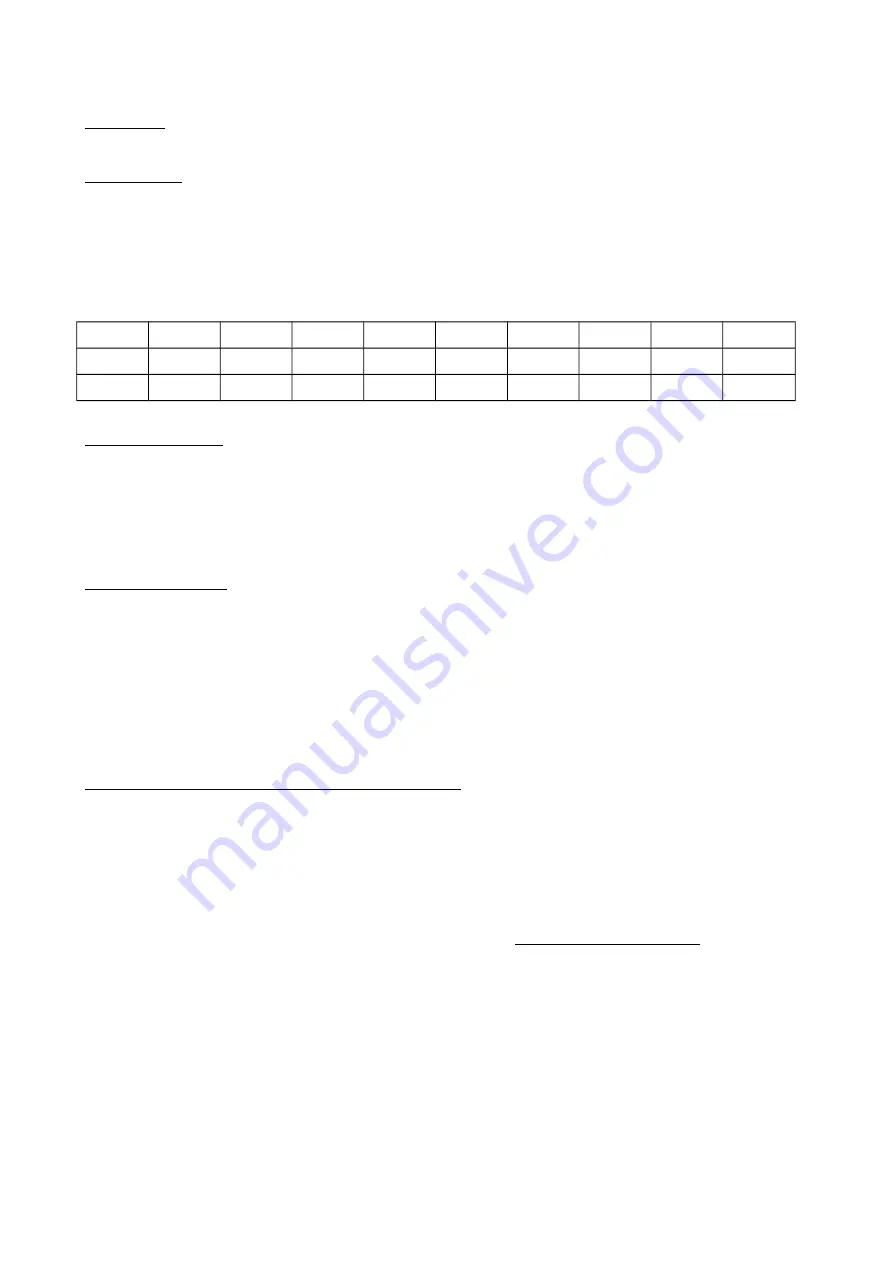

Table 1: Rigging colour coding

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

Grey

White

0

1

2

3

4

5

6

7

8

9

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

Replacement interval

Normal rigging wires (2.5mm OD 7 * 7 galvanised wire rope covered to 3.3mm clear PVC.) should be

replaced every 100 hours or annually (See also COMPONENT LIFE page 24)

Competition thin lower rigging (2mm OD 1 * 19 and 2mm OD 7 * 7 galvanised wire rope.) should be

replaced every 50 hours or more frequently.

Thin Lower Rigging

Only For Competitions!

These wires are slightly thinner than standard wires and they have no protective plastic covering. Their use

is recommended only for competition flying. The main ‘problem’ with these rigging wire lies in the fact that

they are less flexible than 2.5mm OD 7*7 wires and need replacing much more frequently. In addition,

without a protective plastic coating, it is highly recommended that a pilot using these wires flies with suitable

face protection (i.e. full face helmet and visor) and gloves. Gloves may also be required for your ground

crew while ground handling.

Strength and Reduced Life of 1 * 19 galvanised wire rope

This galvanised steel wire rope is theoretically the same strength as the normal rigging used. However

Avian's testing suggests that, when made into rigging, the resulting cables are not as strong, even when brand

new. Thus it is even more important that kinked cables should be replaced immediately. Once a cable has a

kink the strands are damaged and replacement is the only cure. Before every flight check for cable damage

along the entire wire length. The most likely failure area lies immediately adjacent to the swaged fitting.

Look carefully for signs of strand fracture at this position at both wire ends. These wires are much less

flexible and extra care should be taken not to kink the wires when packing or rigging the glider. Due to the

shorter 'life' of these wires it is especially important to replace, even apparently undamaged rigging wires,

every 50 hours of flying or more frequently.

If in doubt specify normal rigging. Avian test pilots use normal 2.5mm OD 7 * 7 plastic coated rigging for

all flying except competitions.

Puma 13.5 hand book-Rev-02

32

Summary of Contents for PUMA 13.5

Page 1: ...PUMA 13 5...

Page 21: ...Puma 13 5 Owner s Manual Figure 4 Checking batten tension Puma 13 5 hand book Rev 02 21...

Page 38: ...Puma 13 5 Owner s Manual Section 3 Assembly Drawings Puma 13 5 hand book Rev 02 38...

Page 39: ...Puma 13 5 Owner s Manual NOSE ASSEMBLY Figure 10 Nose assembly Puma 13 5 hand book Rev 02 39...