11

4. Preset pressure value will be set after three seconds.

5. Press Start switch to inflate. When it reaches the preset pressure value,

the device will stop working.

NOTE:

1. To reset the tire pressure measurement unit, press "On/Unit" to

reselect after setting preset pressure value.

2. Digital gauge records the preset measurement unit and value of

last time operation

3. After the air pump reaches the preset pressure value, the digital

gauge will go off after 60 seconds, and the device will shut down

automatically.

4. Maximum PSI for this unit is 100 PSI.

OPERATING

3. Press “+” or “-” button to adjust preset tire pressure.

(1) Long press “+” or “-” button to adjust working pressure quickly.

(2) Short press “+” or “-” button to adjust preset working pressure.

Note: increment by 0.05BAR & KG/ CM, 1 PSI, 5KPA

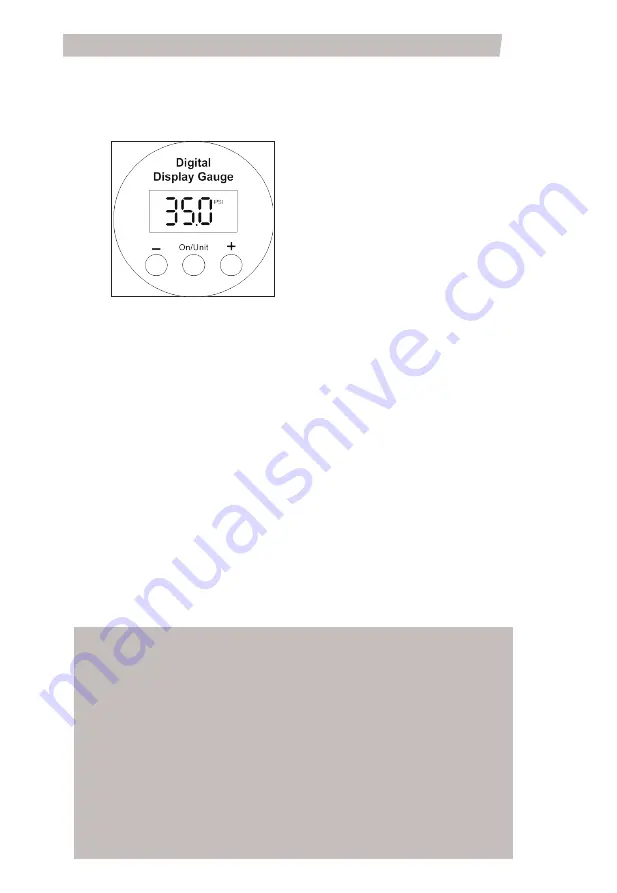

Step 3: Set the Pressure Value (Fig.8)

1. Press “On/Unit” button to read the current tire pressure on the gauge.

2. Press “On/Unit” button again to select tire pressure measurement unit

from PSI, BAR, KPA, KG/CM.

Note: The inflator has a tolerance of + or – 2 PSI. For every 10 minutes

of continuous use, 3 minutes of cool down time are required.

Always leave the hose free of obstructions when the tool is not

in use. Overheating could occur if the hose is blocked.

NOTE:

Fig.8