14

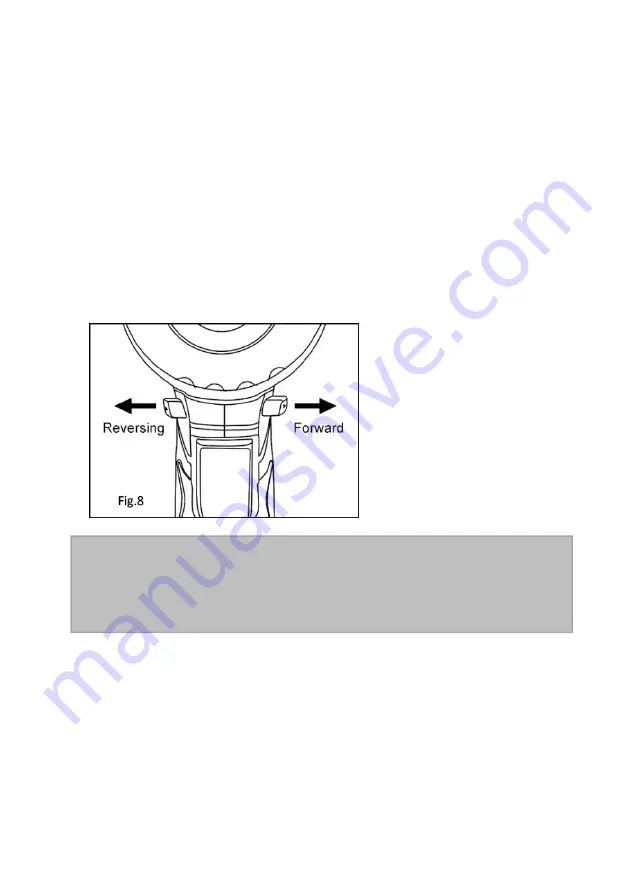

serves as a lock-off button. You can choose between clockwise and

anticlockwise rotation. To avoid causing damage to the gearing it is

advisable to change the direction of rotation only when the tool is at a

standstill.

2. To select forward rotation, release the trigger switch and depress the

forward/reverse control button on the right side of the tool.

3. To select reverse rotation, depress the forward/reverse control button on

the left side of the tool.

NOTE: The first time the tool is run after changing the direction of rotation, you

may hear a click on start up. This and the impacting noise that the tool makes is

normal and does not indicate a problem.

GEAR SHIFTING (Fig.9)

The tool is equipped with two separate gear ranges, low gear, and high

gear. Low gear provides high-torque and slower drilling speeds for

heavy-duty work or for driving screws. High gear provides faster speeds

Summary of Contents for ACD306-N

Page 20: ...19 SCHEMATIC DRAWING ...

Page 21: ...20 ...