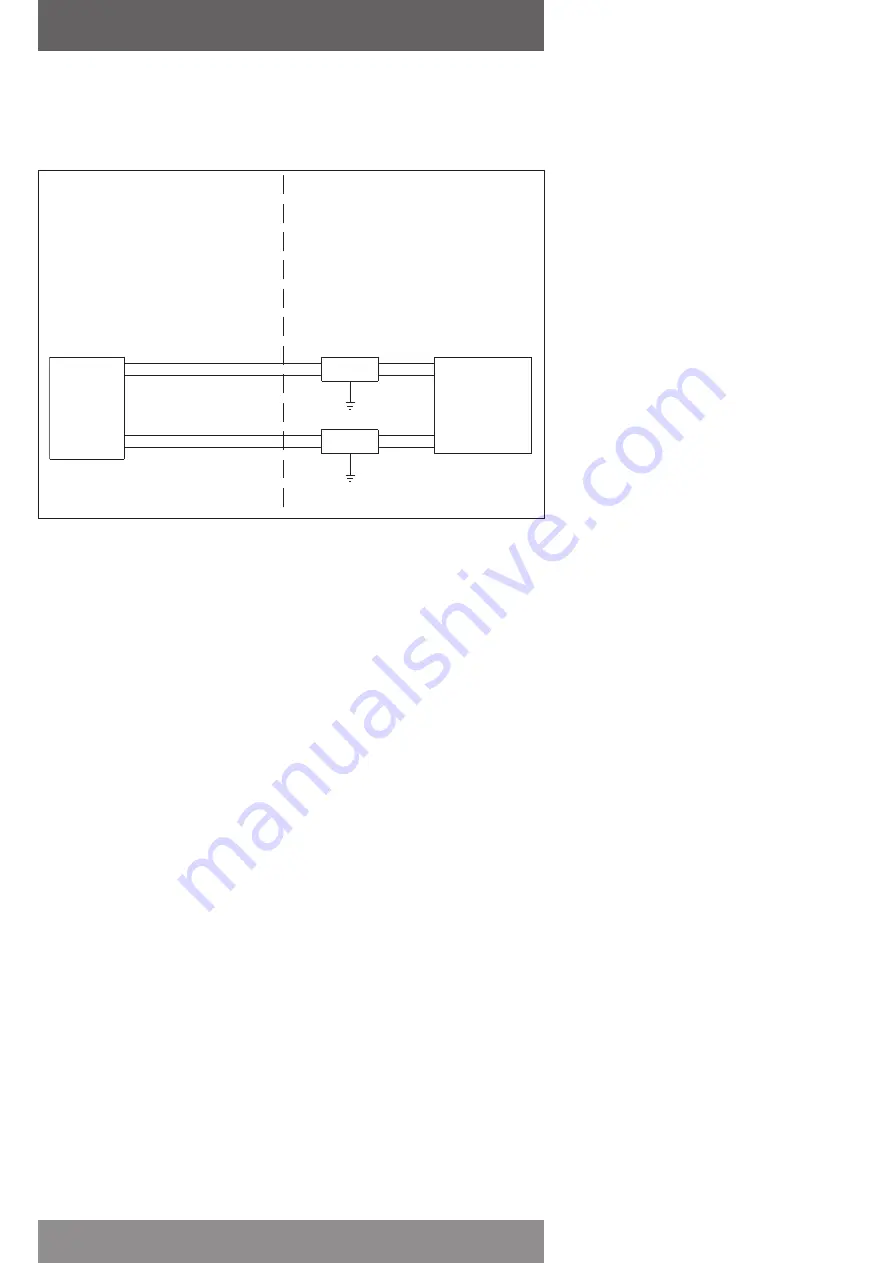

Control schematic for wiring of intrinsically safe positioner for US & Canada (Sheet 4 of 4)

Hazardous location

Class I, DIV 1, Groups A,B,C,D

Class II, DIV 1, Groups E,F,G

SmartCal series

positioner

Associated apparatus

(Intrinsic safety barriers)

Notes 1 & 2

Control

equipment

Note 4

Note 5

4-20 mA

Analog

output

Nonhazardous location

Entity parameters for each field wiring terminal pair of SmartCal:

Vmax = 30 V

Imax = 100 mA

Pi = 0.75 Watt

Ci = 0 pF

Li = 17.25 µH

CSA notes

1. Barrier must be a CSA certified, single channel grounded shunt-diode zener barrier or single

channel isolating barrier or one dual channel or two single channel barriers may be used where

both channels have been certified for use together with combined entity parameters.

The following conditions must be satisfied:

Voc or Vo ≤ Vmax or Ui

Ca > Ci + C Cable

Isc or Io ≤ Imax or Ii

La > Li + L Cable

2. Associated apparatus manufacturer’s installation drawing must be followed when installing this

equipment.

3. Control equipment connected to associated apparatus must not use or generate more than 250

V.

4. To maintain intrinsic safety, each field wiring pair (4-20 mA and analog output) must be run in

separate cables separate shields connected to intrinsically safe (associated apparatus) ground.

5. Rosemount® 275 HART® Communicator is NOT FMRC approved for use in Class II and III

Hazardous Locations.

6. For Class II and III locations where rigid metal conduit is not used, seal SmartCal cable entries

against dust and fibers using an appropriate NRTL listed cable gland fitting.

7. Installation should be in accordance with ANSI/ISA RP12.6 and the National Electrical Code

(ANSI/NFPA 70).

8. Install in accordance with Canadian Electrical Code Part 1.

AVID SmartCal valve positioner

Installation & operating instructions

page 40