AVK SEriES 29 HydrAnt

inStAllAtion, opErAtion & mAintEnAncE mAnuAl

4.4. procedure for replacement of AutoFroSt VAlVE

SAFEty prEcAutionS:

Ensure hydrant is closed prior to commencing procedure.

procEdurE For rEmoVAl And rE-ASSEmBly

1) Remove the dust cap from outlet.

2) Insert the fitting tool to the auto frost valve with a twisting motion. Squeeze the lugs of the autofrost valve together and

push upwards, if necessary using a short (stubby) screwdriver, at the same time as pulling the special tool and autofrost

valve up through the hydrant body and outlet.

3) Smear a film of an approved grease on the ‘O’ ring of the new autofrost valve.

Fit the new autofrost valve to the fitting tool with a twisting motion and guide it into the body. Push down sharply so that

the locking lugs protrude through the underside of the body.

4) Carefully open the hydrant to check satisfactory sealing under pressure. The autofrost valve will seal above 0.5 Bar

pressure.

Ensure personnel are not directly above outlet during this part of the procedure.

Then close hydrant and check that autofrost valve is draining correctly.

5) Refit outlet dust cap to outlet.

tESt

On completion of Maintenance requirements:

1) Check all item are located correctly.

2) Check that all screws are secure.

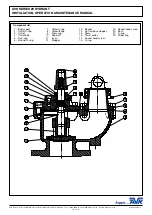

3) Remove dust cap (5) from outlet (3).

SAFEty notE:

When pressurising the main, it is highly recommended that the hydrant is fractionally open to allow venting of air.

4) Check integrity of stopper (obturator) by closing the hydrant in the direction of the arrow on the bonnet.

5) Check integrity of the seals by SLOWLY opening the hydrant.

6) When all tests have proved satisfactory, close the hydrant.

7) Ensure dust cap (5) is always refitted to the outlet (3) when hydrant is not in use. This will prevent the ingress of foreign

matter, stones etc.

AVK Valves Pty Ltd, 559A Grand Junction Road, Wingfield, SA 5013, Australia - T: +61 8 8368 0900 - E: enquiries@avkau.com.au - W: www.avkcivil.com.au Version number 3

COPYRIGHT©AVK GROUP A/S 2017

pp. 6 of 6