5

SECTION 3

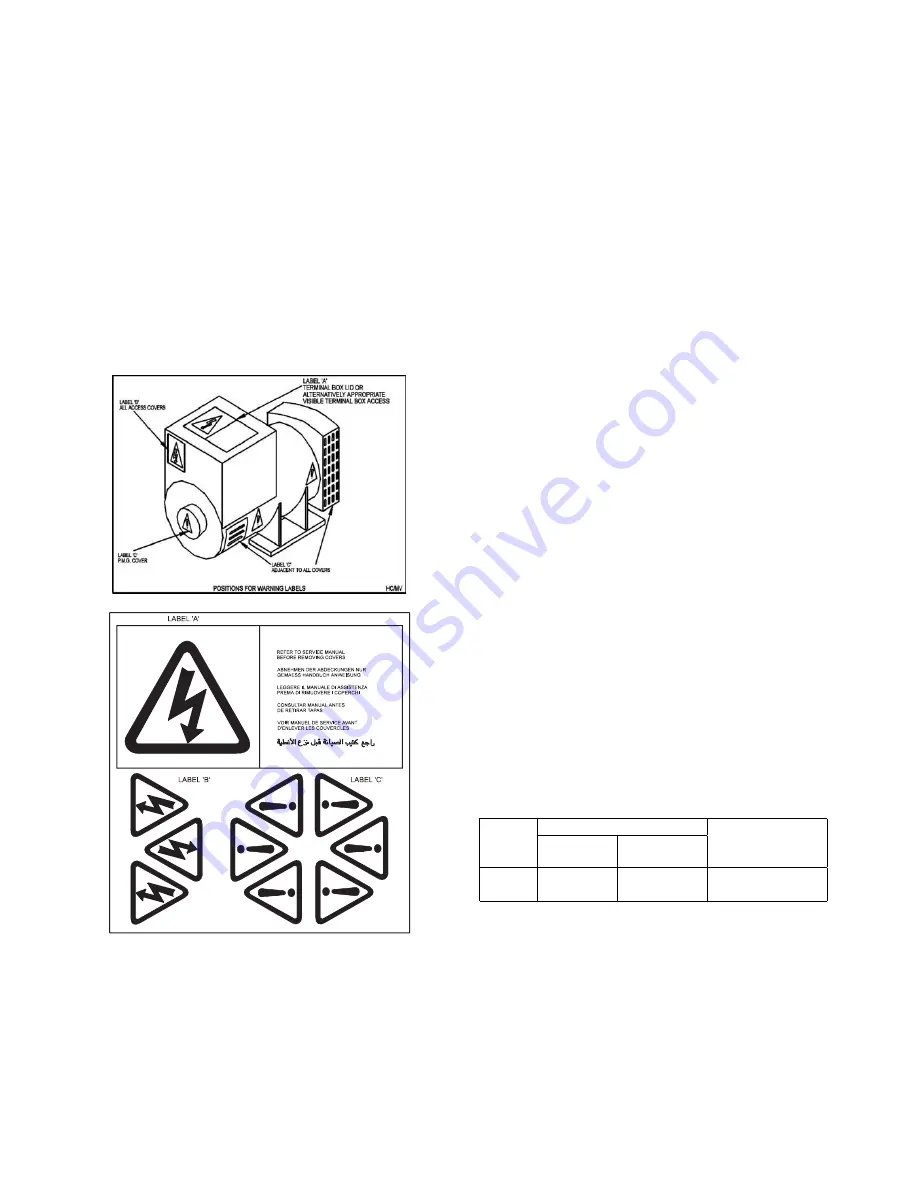

APPLICATION OF THE GENERATOR

The generator is supplied as a component part for

installation in a generating set. It is not, therefore, practicable

to fit all the necessary warning/hazard labels during

generator manufacture. The additional labels required are

packaged with this Manual, together with a drawing

identifying their locations. (See below).

Information labels regarding bearing type, bearing grease,

and re-lubrication information have been fitted to each end

plate adjacent to bearing.

It is the responsibility of the generating set manufacturer to

ensure that the correct labels are fitted, and are clearly

visible.

The ambient conditions in which a generator is operated or

stored should be fully understood, to ensure the generator is

maintained in a fully serviceable condition. Areas for

consideration include temperature, humidity and even

vibration levels.

Temperatures should be stable, but if combined with high

humidity levels, anti-condensation heaters should be

connected to a suitable single phase mains supply. Within

the generator's storage or installed area, thermostatic control

of space heaters will be of considerable assistance.

If the generator is subjected to conditions which result in

condensation forming within the generator, steps must be

taken to ventilate and heat the generator. The winding

insulation resistance must be measured and be above the

minimum values stated in section 4.4.1.1 of this book before

the generator is put into service.

Subjecting stationary generators to vibration will cause

damage to the generator ball bearings, the process termed

brinelling.

The generators have been designed for use in a maximum

ambient temperature of 40°C. in accordance with B.S. 5000.

Ambients in excess of 40°C. can be tolerated with reduced

ratings - refer to the generator nameplate for rating and

ambient. In the event that the generator is required to

operate in an ambient in excess of the nameplate value or at

altitudes in excess of 1000 metres above sea level, refer to

the factory.

The generators are of air-ventilated screen protected drip-

proof design and are not suitable for mounting outdoors

unless adequately protected by the use of canopies. Anti-

condensation heaters are recommended during storage and

for standby duty to ensure winding insulation is maintained in

good condition.

When installed in a closed canopy it must be ensured that

the ambient temperature of the cooling air to the generator

does not exceed that for which the generator has been rated.

The canopy should be designed such that the engine air

intake to the canopy is separated from the generator intake,

particularly where the radiator cooling fan is required to draw

air into the canopy. In addition the generator air intake to the

canopy should be designed such that the ingress of moisture

is prohibited, preferably by use of a two stage filter.

The air intake/outlet must be suitable for the air flow given in

the following table with additional pressure drops less than or

equal to those given below:

Air Flow

Frame

50Hz

60Hz

Additional

(intake/outlet)

Pressure Drop

8

4.1m

3

/sec

(8680cfm)

4.8m

3

/sec

(10170cfm)

6mm water gauge

Important !

Reduction in cooling air flow or

inadequate protection to the

generator can result in damage

and/or failure of windings.

Dynamic balancing of the generator rotor assembly has been

carried out during manufacture in accordance with BS 6861

Part 1 Grade 2.5 to ensure vibration limits of the generator

are in accordance with BS 4999 Part 142.