Page 5-6

ADJUSTING THE SIZE OF THE SECTION

Line up the tension box approximately behind the section you will be

winding. Now wind about one yard onto the beam. As you wind, you

will need to fine tune the placement of the tension box along the track.

When it is centered properly, tighten down the wing nuts under the

tension box. At this point, you can pivot the “pivoting reed section” so

that the yarn comes close to, but doesn’t quite touch, either the peg to

the left or the peg to the right. Now tighten the wing nut under the

pivoting reed. This shouldn’t need to be readjusted until you are using

yarn of a very different size.

Extra care to correctly center and adjust the width of each warp section

will result in more perfect tension while weaving.

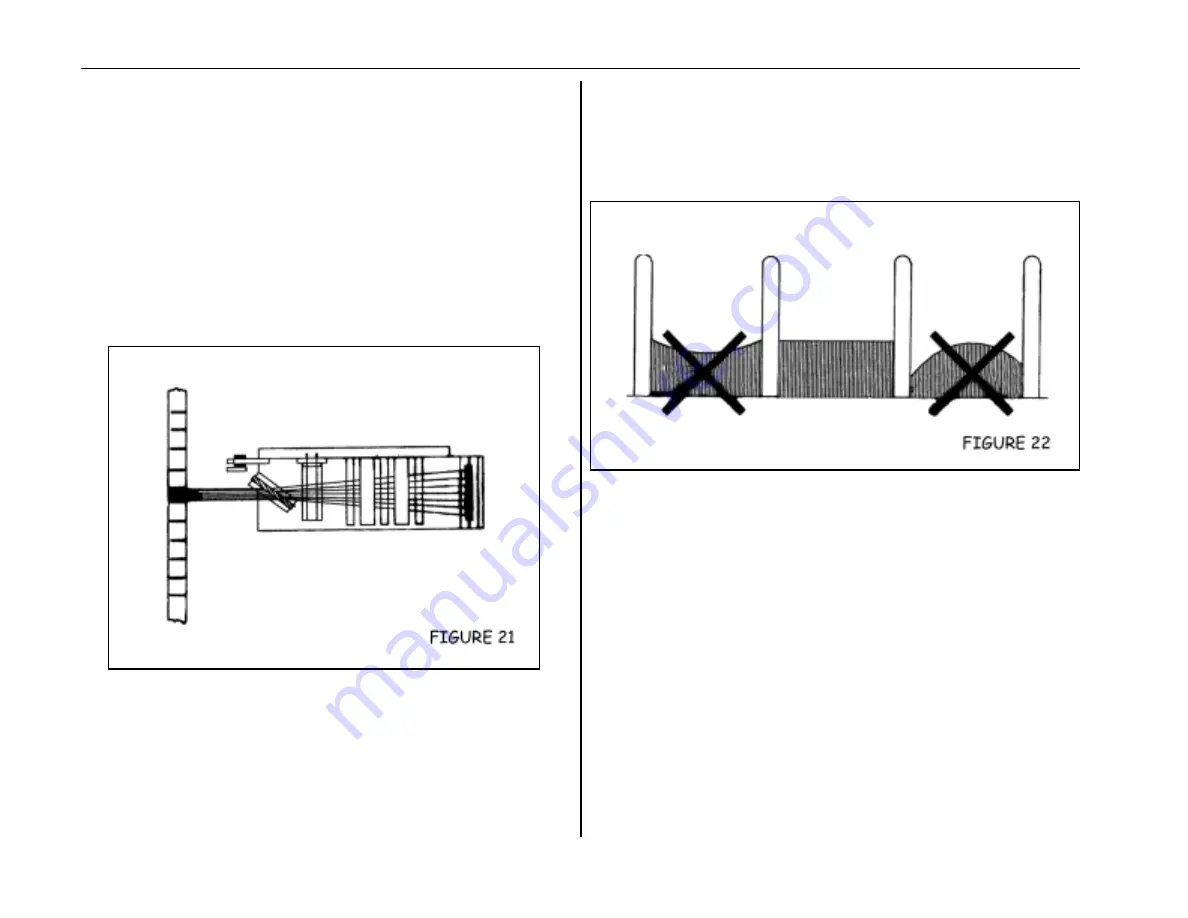

Make sure that the threads are going on to the beam in flat layers. If you

notice that warp piles up at the pegs, the section of the warp is too wide.

If the warp falls down at the pegs, the warp section is too narrow.

If any of the above is happening, go back and pivot the front reed on the

tension box again until you get perfectly flat layers. This is very impor-

tant, otherwise you will end up having different length threads in one

section, since the circumference of the beam within the section is not

going to grow evenly. Therefore, you will end up having lots of tension

problems.