Page 2-11

17.)

Before proceeding to the weaving section, you should take a minute to see that all the harness cables and treadle cables are seated in the

correct pulleys and are routed properly.

18.)

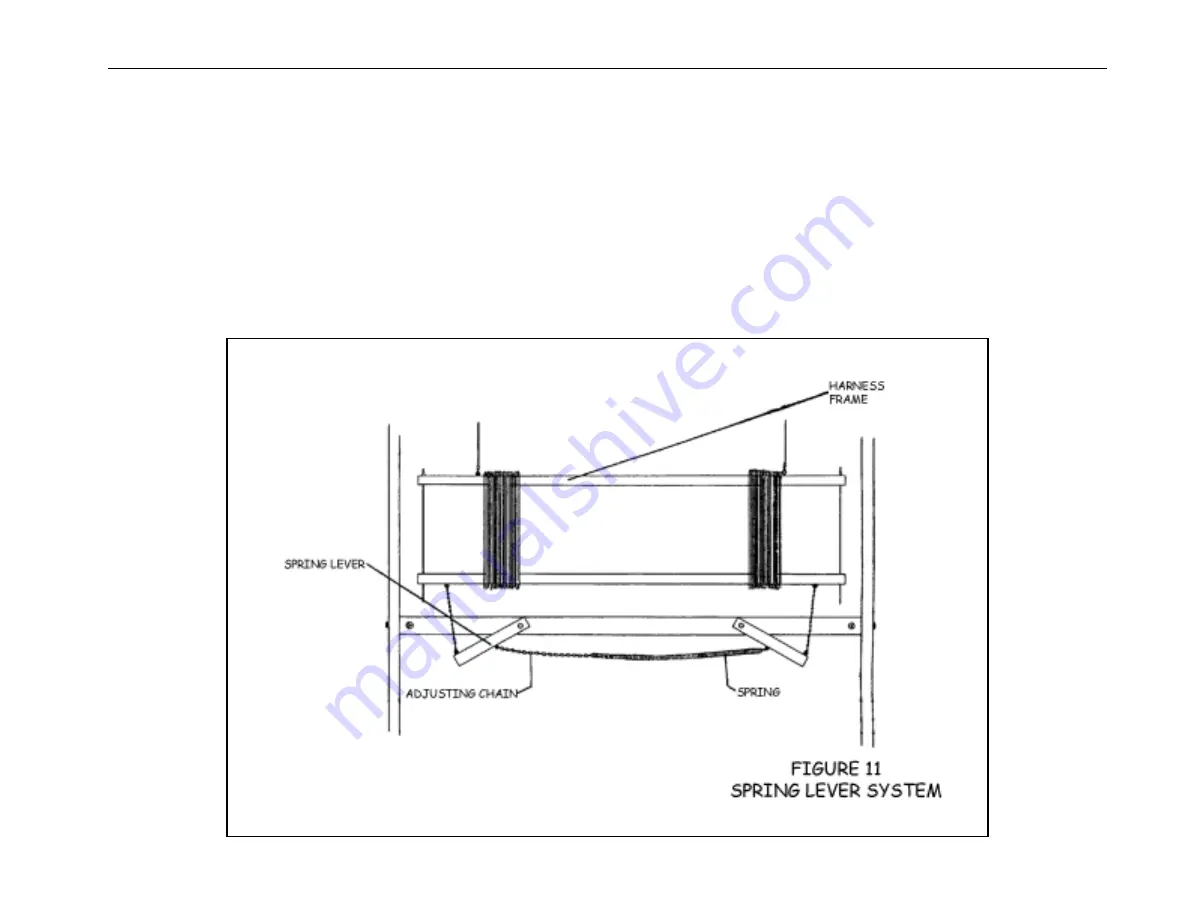

One last thing to check is the spring lever system. This system is located directly underneath the harnesses and is made up of two rows of

wooden levers with springs and chain between them. The purpose of these spring levers is to hold the unraised warp ends in the lower

position, thereby giving you the best possible shed or opening to pass your shuttle through. Each set of spring levers is adjusted by tightening

the spring that is between them. This is done by simply tightening the chain that is attached to the spring. Generally speaking, the tighter

the warp tension, the tighter the spring lever tension should be. You may also find that harnesses with a high number of warp ends will

require a somewhat higher spring lever tension as well. You will know when you have achieved the proper amount of tension when the

unraised warp ends all lay flat against the shuttle race. For now, just make sure that all of the chains and springs are hooked up properly.

Each harness frame should be attached to the set of spring levers below it (as shown in Figure 11).