Additional Loom Information

K-Series Loom User Manual

Page | 130

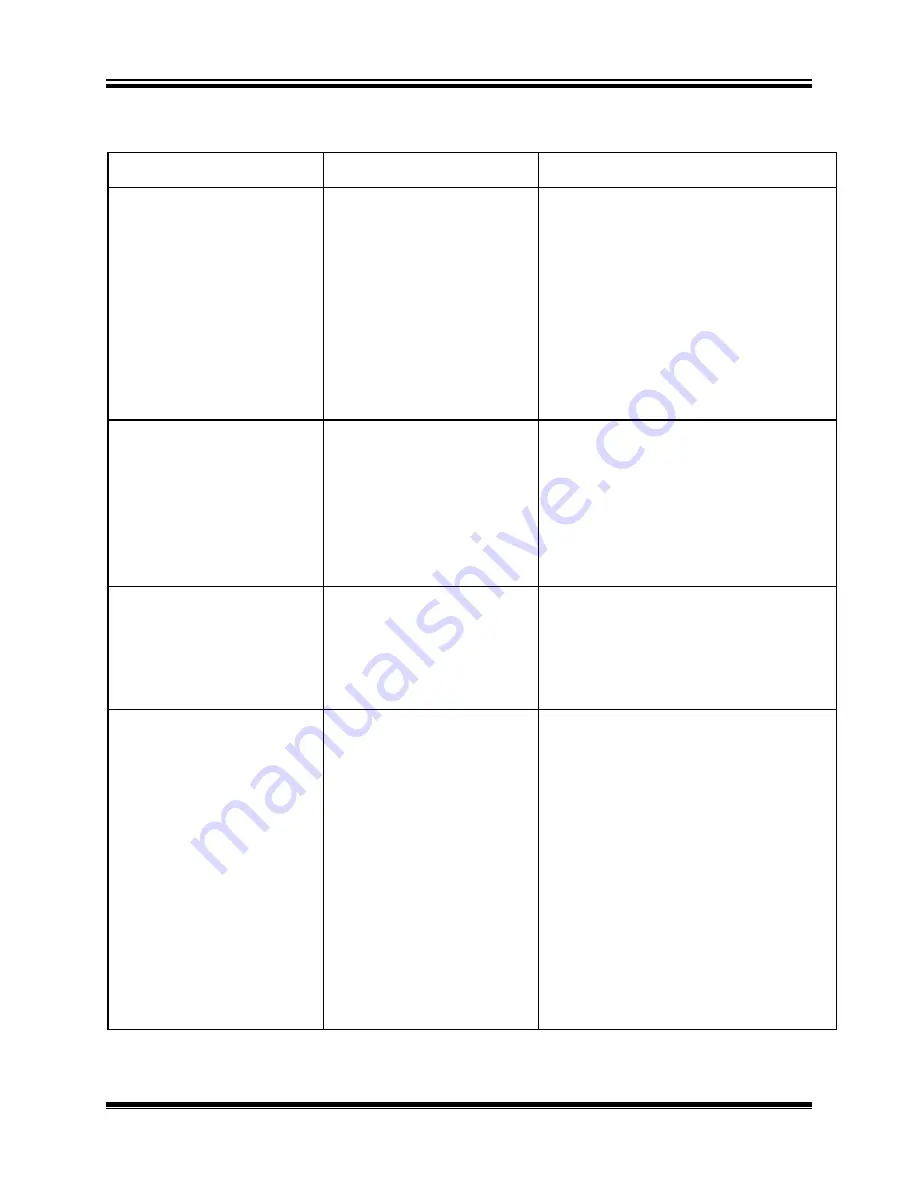

Troubleshooting

Tension

Symptom

Possible Cause

How to Fix It

A) Your Warp Beam

won’t hold tension.

1) You have mis-

routed your brake

cable. If you have

just installed the

system, or

disconnected your

Brake Cable to move

the loom, you may

very well have

incorrectly replaced it.

Review the cable routing as

shown in the Assembly

Section.

2) You may have

warped your beam

backwards. Consult

the Weaving Section

which illustrates how

your warp should be

routed.

If you did warp your beam

backwards, you will need to

remove the warp and start

over.

3) The sandpaper on

your Cloth Beam is

not grabbing the warp

and pulling it around

as it should

You’ll very likely need to add

SoftGrip or another kind of

beam cover in order to get

satisfactory warp tension.

B) Your warp tension

is different in different

places over the width

of the warp.

1) It is not indicative

of a tensioning

problem. It is a

matter of not having

maintained even

tension when warping

the beam and there’s

no redress from the

Tension System. It’s

just too late for this

warp to be well

tensioned.

You should have used a

Warping Wheel for sectional

warping or craft paper for plain

beam warping. If you do not

want to waste this warp, place

something (folded paper or

cloth) in the areas on the

beam where your tension is

looser. You will have to move

your paper every time you

advance the warp and also

keep adding more since it will

probably become looser and

looser.