K-Series Loom User Manual

Additional Loom Information

Troubleshooting

Page | 131

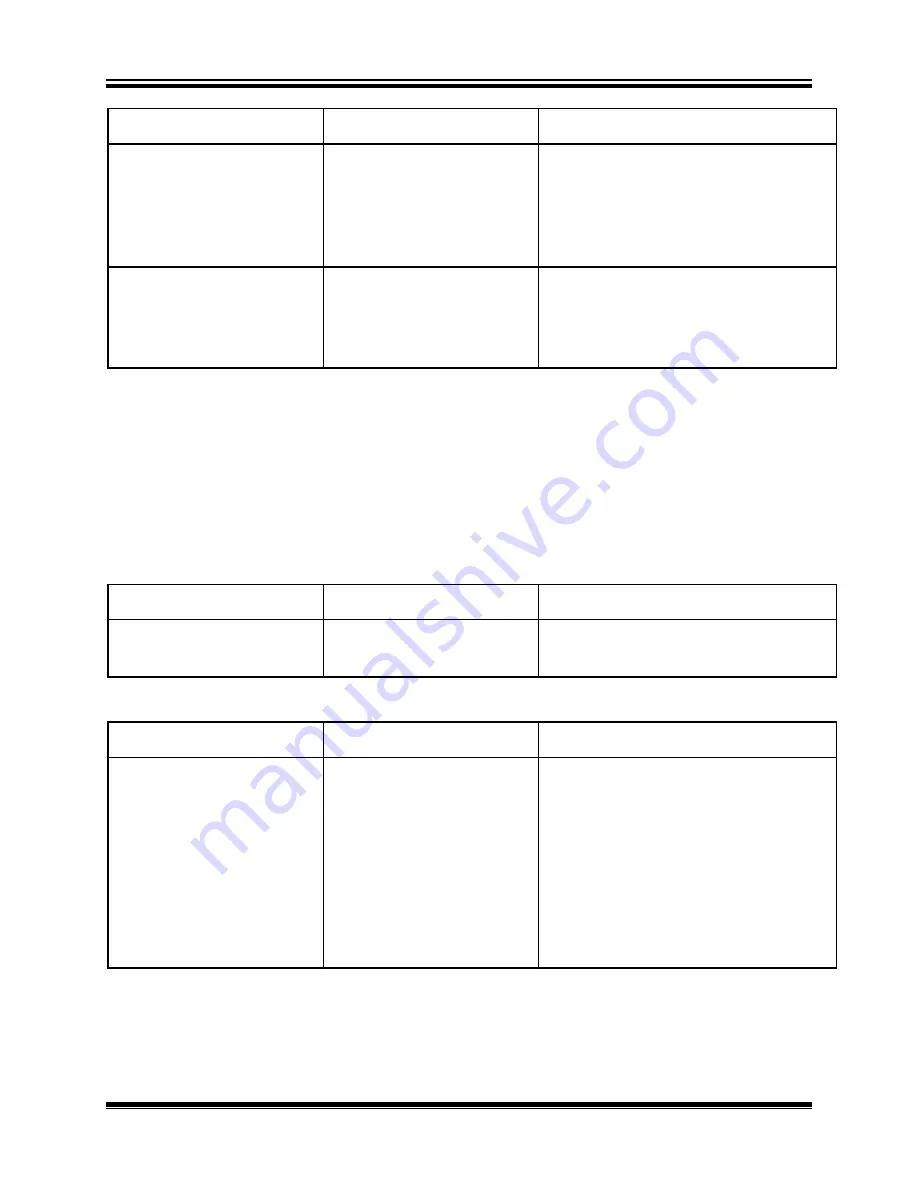

Symptom

Possible Cause

How to Fix It

C) Excessive tension

on the warp.

2) The tension cable

has gotten crossed

over itself on the

warp beam brake

drum.

Straighten out the cable.

D) Cloth is not

wrapping around the

cloth storage beam

correctly.

1) The clutch

controlling the cloth

storage beam may

need tightened.

Tighten the bolt on the cloth

storage beam. See page 44.

The Shed

AVLs are designed with a shed which exactly meets the need; not too wide,

not too narrow. And there is, of course, a reason for this precision. Raising

harnesses higher than you need may give you a larger shed, but it’s also a

waste of time and effort. You only need enough warp separation for the

shuttle to pass freely. However, because the shed on AVLs is so precisely

calibrated, you do need to be sure that you’re getting all that the loom can

deliver.

Symptom

Possible Cause

How to Fix It

A) Restricted Sheds.

1) Treadle cables fell

off the pulleys.

Replace the treadle cables so

they go over the pulleys.

Beaters

Symptom

Possible Cause

How to Fix It

B) One side of your

fabric is beaten more

tightly than the other,

even if you are

holding your beater in

the middle. You have

a diagonal beat line

rather than

horizontal.

1) Your beater is out

of alignment.

To check, push your beater all

the way back against the

Beater Bumper Blocks, it

should strike both sides at

exactly the same time. If it

doesn’t, you’ll need to adjust

the bolts holding the beater to

the loom.