Rug Loom User’s Manual

Introductory Information

Air Component Information

Page | 7

Piloted Valve

This valve directs the flow of air to and from different parts of the system.

Rod End

The working end of an air cylinder which connects to the mechanism that

needs to be moved.

Air Compressor Requirements

Compressors are rated according to the volume of compressed air they can

delivery in one minute. This rating is known as C.F.M., cubic feet per

minute.

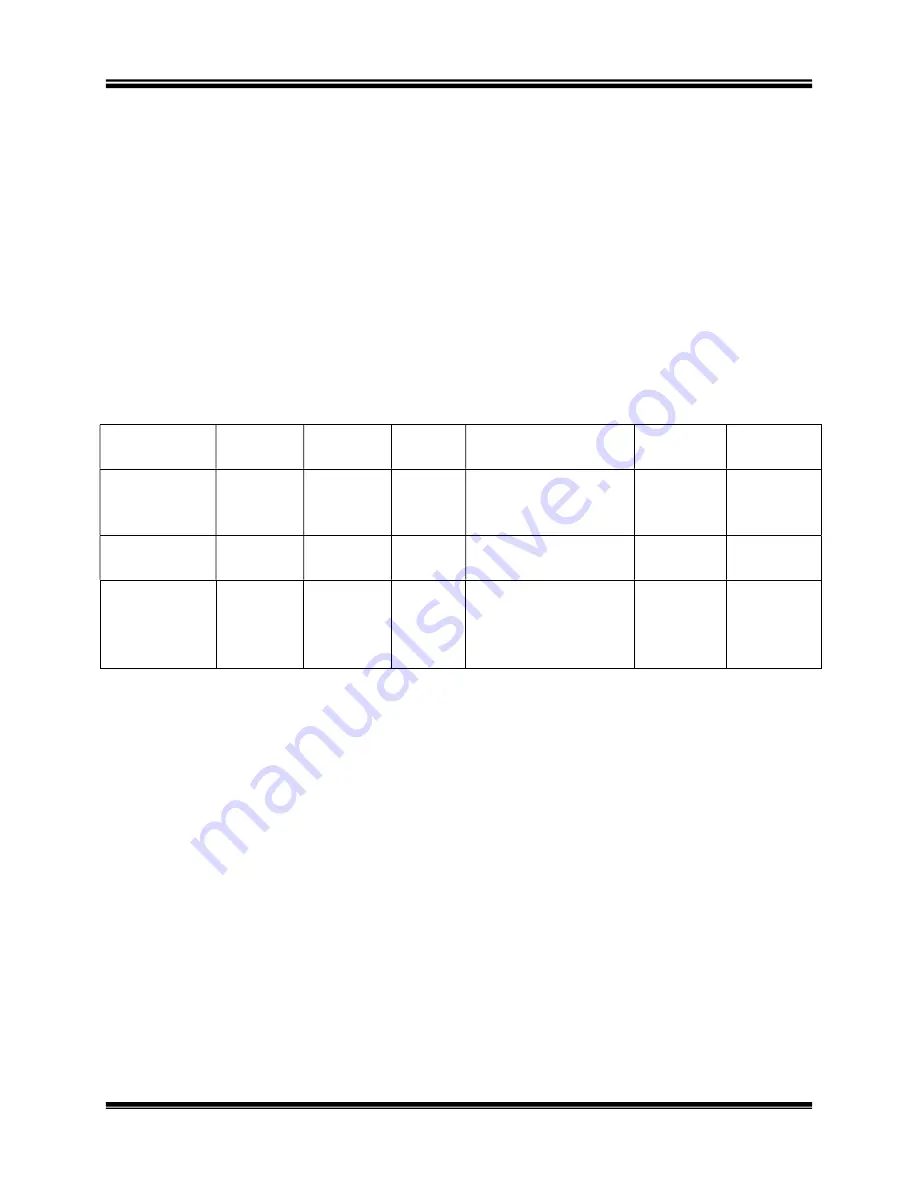

DEVICE

USAGE UNITS PER

COMPRESSOR

RATING *

UNITS NOTES

RL 48 in.,

72 in., 96

in., 120 in.

0.73

CFM @

100 PSI

Loom 2

CFM

Rated @

30 PPM

RL 144 in.,

180 in.

1.45

CFM @

100 PSI

Loom 4

CFM

Rated @

30 PPM

Air-

Assisted

Shuttle

Boxes

0.47

CFM @

100 PSI

Loom 2

CFM

Rated @

60 PPM

PPM = Picks Per Minute

CFM = Cubic Feet Per Minute

PSI = Pounds Per Square Inch

We suggest sizing a compressor for worst case scenarios like 50% duty

cycle. When using a 50% duty cycle, doubling the usage rate is the first

step, then adding another 50% will insure the compressor is not working at

maximum capacity, making it last longer and delivering reliable compressed

air to AVL products.

Note:

If you will be using multiple air components, make sure your air compressor

is sized to handle all of them.

Exceptions to the above sizing methods are products that may use

compressors other than the reciprocating type. Screw type compressors are

Summary of Contents for Rug Loom

Page 2: ......

Page 5: ...Rug Loom User s Manual Introductory Information Page 1 INTRODUCTORY INFORMATION ...

Page 14: ......

Page 15: ...Rug Loom User s Manual Loom Assembly Set Up Page 11 LOOM ASSEMBLY ...

Page 64: ......

Page 84: ......

Page 115: ...Rug Loom User s Manual The Fine Print Removing Cloth from the Loom Page 111 THE FINE PRINT ...