Model 1200K/1210K - RCI SNG ANTENNA SYSTEM

11

Operation and Maintenance Manual

Figure 3.4

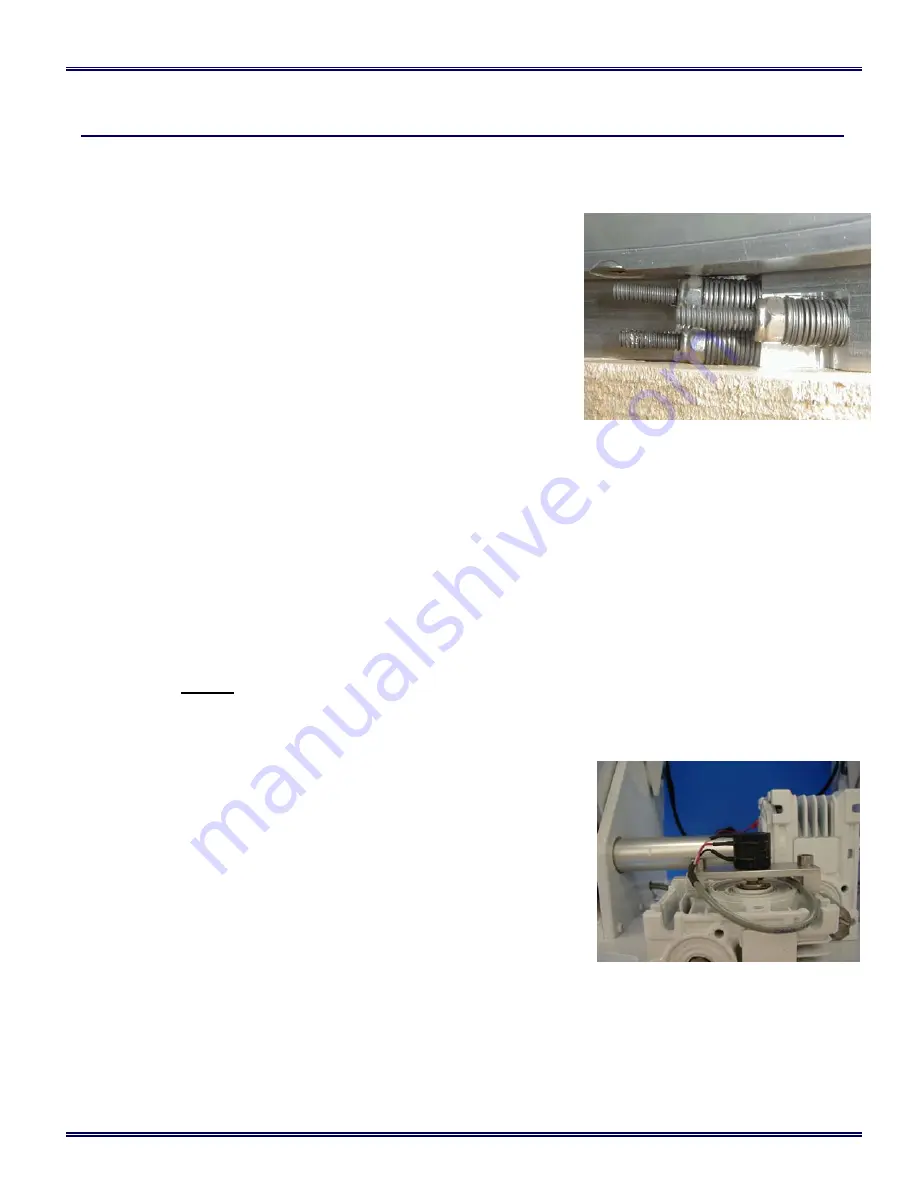

3.4 AZIMUTH ROTO-LOK® CABLE DRIVE

The patented azimuth Roto-Lok® drive produces a drive system

with zero backlash, high stiffness, no wear, no lubrication, and

maximum reliability. The system consists of three or four 1/16, 7 x

19 stainless steel aircraft control cables reverse wrapped twice

around the grooved capstan and once around the drum, with solid

connections on one end and high force, Belleville springs on the

other end (Fig 3.3.) One cable has the capacity to withstand a 75

mph wind load. The additional cables are used to provided

increased stiffness and drive redundancy.

If a cable becomes

damaged during usage, cut off cable and continue to use

positioner. Replace cable when time permits at your

maintenance facility.

The cables are sized to last the life of the positioner. The springs

will automatically compensate for

any elongation of the cable.

Cable position should be checked as per the periodic maintenance schedule in Section 7. If cables

have drifted, manually move cables using blunt instrument on azimuth drum until correct position is

obtained.

At installation the Belleville springs are collapsed until no “air” is seen between the springs. You

should check this condition yearly to account for the slow settling of the cable strands. Use pliers

to hold stud and ¼ box end wrench to tighten nut.

Be sure not to over tighten. Tighten until

springs are almost fully collapsed.

(Fig 3.3)

3.5 AZIMUTH POSITION FEEDBACK

The azimuth position feedback is produced by a 10 turn, 1K-ohm

potentiometer driven by the output shaft of the worm gear box. (Fig

3.4) Since the Roto-Lok drive has no backlash, the position feedback

is as accurate (1%) as the resolution (.3°) and accuracy of the

potentiometer and the backlash between the potentiometer and the

azimuth capstan. The potentiometer is sealed and rated for IP 65

environment - wind, rain, dust, etc.

The potentiometer is mounted on a bracket that straddles the az gear

box. The azimuth potentiometer is slotted and driven with a cross pin

in the az capstan. The potentiometer is mechanically centered at the

travel position ( 5 turns from either end ) when az platform is in the az

stow position. This is accomplished by loosening the ½” nut, which

secures the potentiometer to the bracket. The potentiometer may

also be electrically zeroed by the controller. See Section 2.3

in the RCI 3000/3050 Controller manual.

Figure 3.3