Model 1200K/1210K - RCI SNG ANTENNA SYSTEM

13

Operation and Maintenance Manual

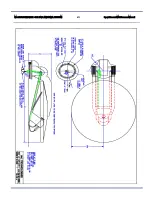

Figure 4.1

Figure 4.2

SECTION 4 - ELEVATION POSITIONING SYSTEM

4.1 ELEVATION PIVOT ASSEMBLY

The elevation pivot assembly consists of two elevation drum assemblies

pivoting between two clevis blades assemblies. The drum shafts pivot in

hi-tech plastic bushings. (Fig 4.1) No maintenance is required. If

squeaking noise is heard, simply spray silicone lubricant with “straw”

nozzle down between the drum side and clevis plate on to the pivot shaft.

4.2 ELEVATION GEARBOX

The elevation gearbox is a low backlash (30') worm gear box. The worm

gear drive isolates any backlash in the motor drive from the system. In

addition, since it is a 40:1 ratio it will not back drive, eliminating any need

for a brake on the drive train.

The motor drives the input worm via a quill/female hole and square

key. The worm shaft is extended with a hex shape adapter for the

hand crank. The dual elevation capstans are driven with a square

key and clamped to the gearbox shaft to eliminate backlash. (Fig 4.2)

The gearbox contains synthetic oil filled half-way to the level plugs.

Because of the design capacity of the gearbox, low rpm and limited

cycles experienced by an SNG system, no maintenance is required.

4.3 ELEVATION MOTOR

The elevation drive motor is a 24V DC motor with integral 32:1 spur

gear train. The motor armature

rotates at up to 3300 rpm causing a high frequency noise that will vary depending of the loading condition

of the motor. (Fig 4.2)

The maximum output speed is 104 rpm. The output shaft is a standard keyed shaft. The output

torque capacity of the motor is rated for the operational wind load.

Since the low backlash worm gear drive, isolates the backlash from the motor, any backlash between

the square key and motor gear train will not be seen by the reflector boresight. No maintenance of

elevation motor is required.