Model 1200K/1210K - RCI SNG ANTENNA SYSTEM

16

Operation and Maintenance Manual

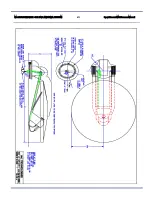

SECTION 5 - FEED AND POLARIZATION POSITIONING SYSTEM

5.1 GENERAL

The Feed assembly consists of feed boom, feed housing, RF components and polarization drive.

The feed boom is pivoted about the elevation axis to eliminate additional flex-guide required if

pivoted at edge of reflector. The pivot connection at the end of the feed arms is with delrin

bushings and shoulder bolts. The elevation wavequide runs along the outside of the feed boom tubes. A

piece of 18" flex waveguide is used at the end of the waveguide tube to the OMT. The feed/OMT is

rotated by worm gear drive and 12V DC motor. Position feedback is from a 10 turn potentiometer.

5.2 FEED

The feed assembly consists of an inclinometer, feed horn and OMT with male pivot bushings. The

male bushings pivot in delrin female bushings at each end of the OMT. These bushings are mounted to

mounting plate. The worm gear attaches to OMT and waveguide attaches to other end with M6

screws at the rear flange of the OMT. The feed/polarization drive is mounted underneath pol mounting

plate with worm mating to worm gear, which extends through slot.

5.3 POLARIZATION DRIVE

The feed/polarization drive is mounted underneath pol

mounting plate with a worm mating to the worm gear,

which extends through a slot. The polarization drive

motor (Fig. 5.1) is a 12V DC gear motor. It is attached to

a coupling, which attaches to the worm. The worm gear

shaft is extended to drive the position potentiometer. This

plugs into standard cigarette lighter and has a toggle

switch to rotate

pol in desired direction. The controller travel limits are +/-

92° for a 2-port and +/-47° for a 4-port.

(See RCI 3000/3050 Controller Manual section 3.3). An

emergency pol drive is available to drive pol motor in case

of controller error or failure. This plugs into standard

cigarette lighter and has a toggle

switch to rotate pol in desired direction.

Since the low backlash worm gear drive isolates the feed from the motor no brake is required. No

maintenance of the Polarization motor/assembly is required.

The polarization drive is replaced a complete unit including the motor, motor bracket, worm, bushings and

worm shaft.

Figure 5.1