Workshop Dobby Loom User’s Manual

Additional Loom Information

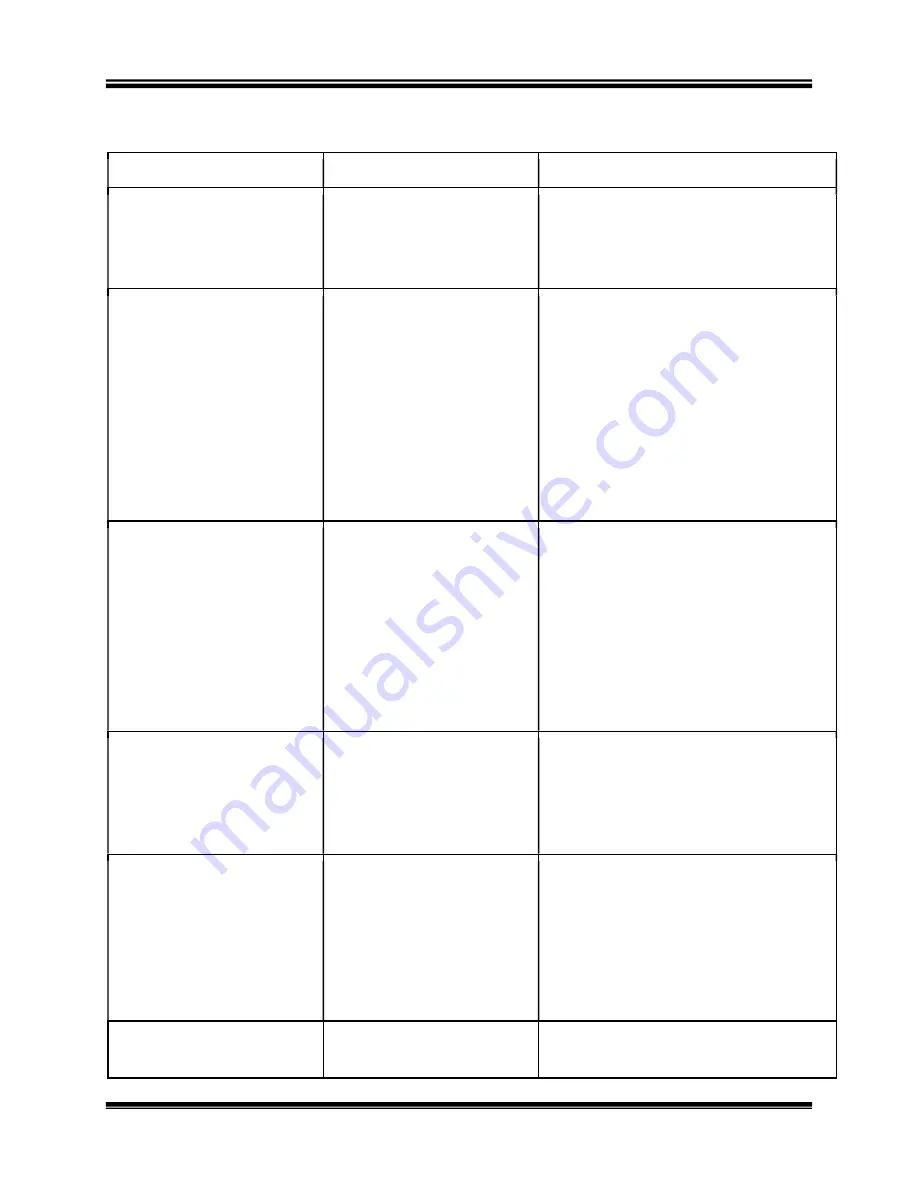

Troubleshooting

Page | 59

Tension

Symptom

Possible Cause

How to Fix It

A) Your Warp Beam

won’t hold tension.

1) Your Tension Tie-

Up has loosened.

Readjust the tie-up and either

tie a bow in the cord ends or

bind it tightly with a double

wrap of cord.

2) You have mis-

routed your brake

cable. If you have

just installed the

system, disconnected

your Brake Cable, to

move the loom, or

warp the beam, you

may very well have

incorrectly replaced it.

Review the cable routing as

shown in the Assembly Section

(Page 11 and following).

3) You may have

warped your beam

backwards. Consult

the Weaving Section

on page 37 which

illustrates how your

warp should be

routed.

If you did warp your beam

backwards, you will need to

reverse your tension cable.

Unclip the cord, loosen the

cable, and wind it in the

opposite direction. This is not a

permanent fix. Use it only to

weave off the warp you wound

backwards.

4) The sandpaper on

your Cloth Beam is

not grabbing the warp

and pulling it around

as it should

You’ll very likely need to add

SoftGrip or another kind of

beam cover in order to get

satisfactory warp tension,

5) The surface of the

Brake Drum has

become polished and

no longer offers

sufficient friction to

grab and hold the

Brake Cable

Disconnect and unwind the

Brake Cable. Lightly sand the

surface of the groove in the

Brake Drum with your #220

sandpaper. Replace the cable

(but be sure about its

routing!).

B) Your warp tension

is different in different

1) It is not indicative

of a tensioning

You should have used a

Warping Wheel for sectional