Using the IDL

Page | 30

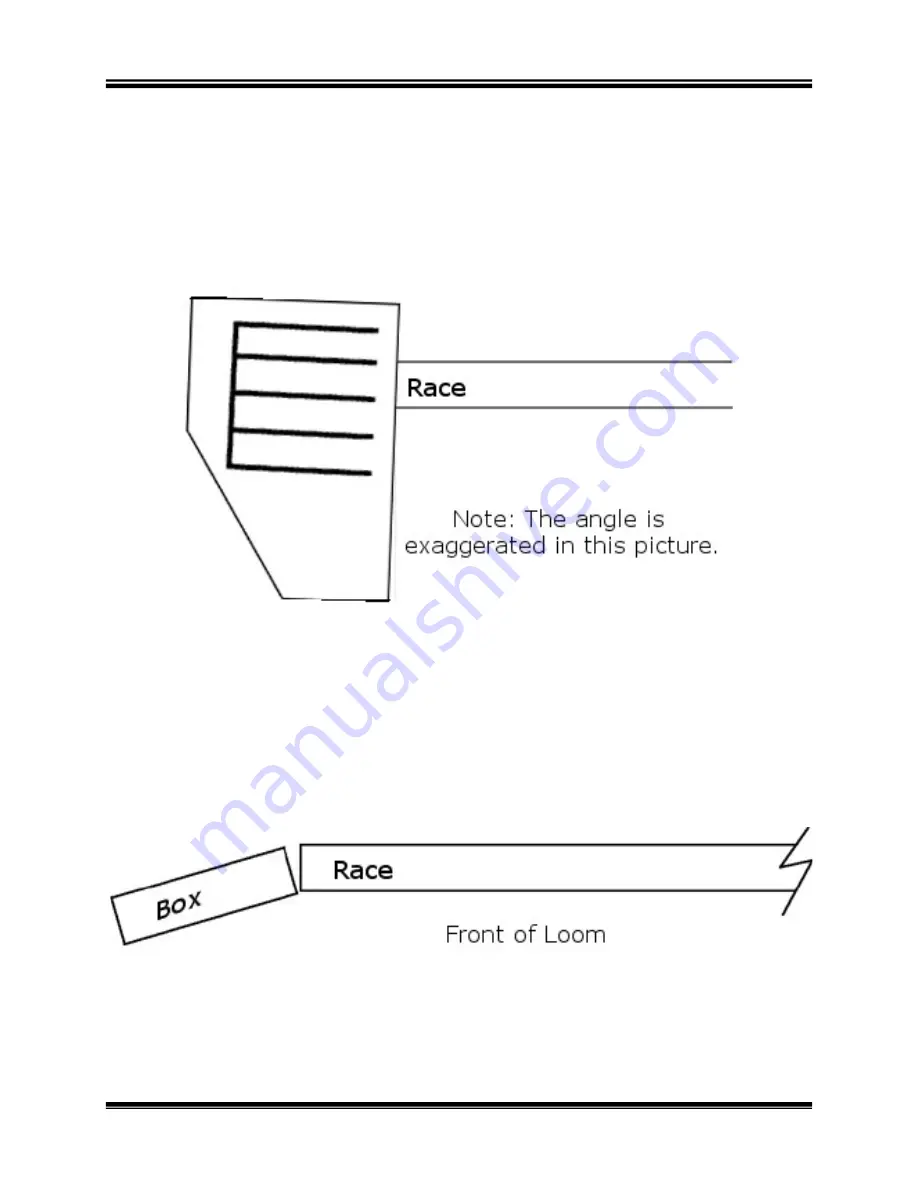

Backplate Tilt

The shuttle boxes on both sides should

relative to the

shuttle race. This angle will cause the shut

race as it travels across.

If the boxes are misaligned in the opposite

an errant trajectory and may

unsafe condition.

Backplate Cant

Both shuttle box assemblies must also carry a slight angle

In the same way that a bit of downward angle causes the shuttle

the race, a slight canting of the backplates will

located against the reed as it travels across

If the backplate is angled too

of the

reed and exit the loom

forward, the shuttle will speed off the race.

Shuttle Box to

Race Alignment

There are two critical alignments to consider

Industrial Dobby Loom User's Manual

The shuttle boxes on both sides should carry a very slight downward angle

shuttle race. This angle will cause the shuttle to “hug” the

the boxes are misaligned in the opposite direction, the shuttle will take on

an errant trajectory and may launch off the race — obviously creating an

lies must also carry a slight angle towards the reed

the same way that a bit of downward angle causes the shuttle

the race, a slight canting of the backplates will keep

the shuttle properly

located against the reed as it travels across the

loom.

oo far back, it will cause the shuttle to bounce off

reed and exit the loom area. If the backplate is angled too far

forward, the shuttle will speed off the race.

Alignment

cal alignments to consider here:

l Dobby Loom User's Manual

Adjustments

slight downward angle

tle to “hug” the

direction, the shuttle will take on

obviously creating an

towards the reed.

the same way that a bit of downward angle causes the shuttle to stick to

the shuttle properly

will cause the shuttle to bounce off

If the backplate is angled too far

Summary of Contents for Industrial Dobby Loom

Page 2: ......

Page 6: ......

Page 10: ......

Page 11: ...Industrial Dobby Loom User s Manual IDL Setup IDL Setup Page 5 IDL SETUP IDL SETUP ...

Page 22: ......

Page 53: ...Industrial Dobby Loom User s Manual Maintenance Maintenance Page 47 MAINTENANCE MAINTENANCE ...

Page 56: ......

Page 64: ......