SETTING TRAVEL LIMITS

9

Motor

Encoder

Mode

O

PRESS

MENU

10.1

Set

Door

Travel

PRESS

FIG. 10

FIG. 11

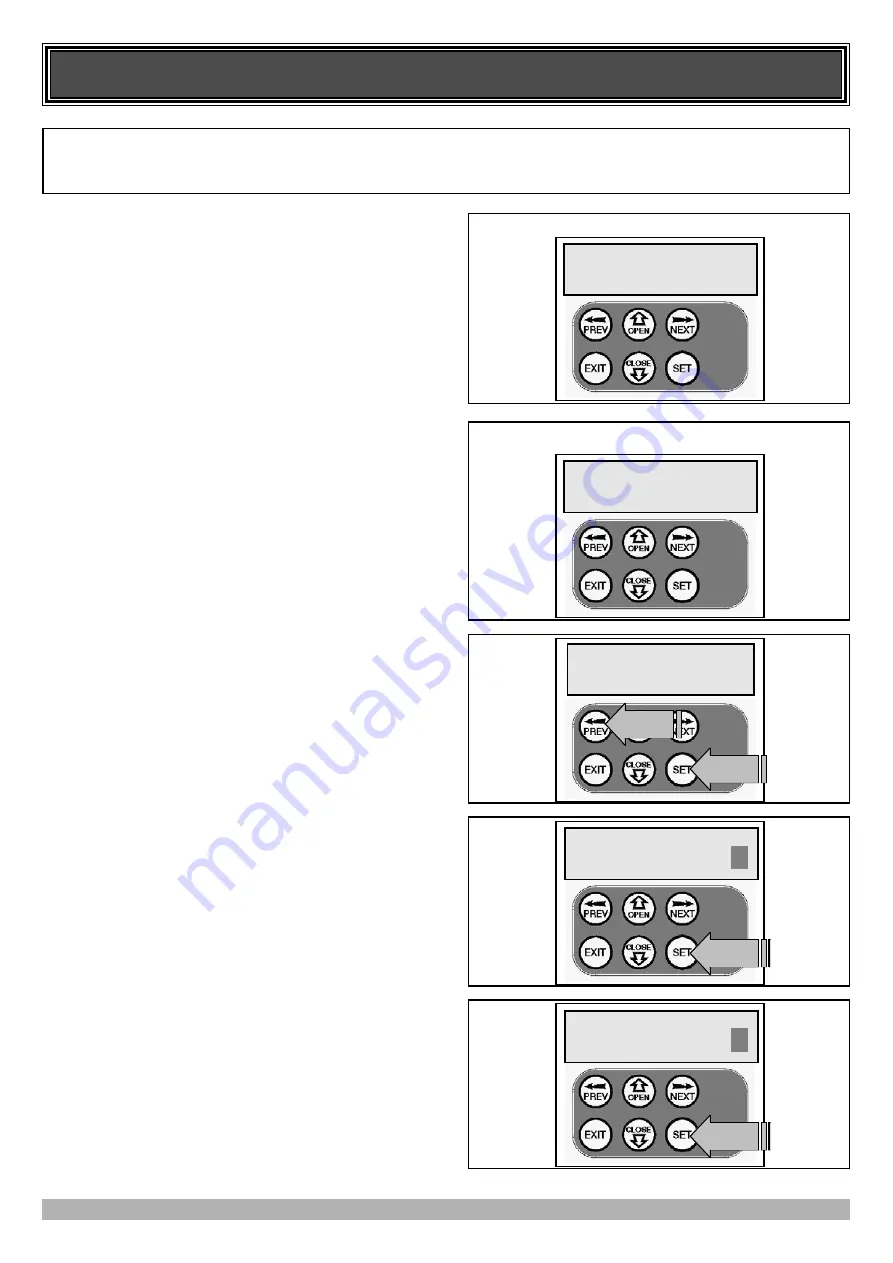

This section shows how to set the travel limits. The procedure can

be partly completed using a transmitter. In order to use a

transmitter it must first have at least one of its buttons coded to the

controller. The function assigned to the transmitter's

buttons is of no concern here as the buttons are temporally assigned

to OPEN, CLOSE and SET.

Note: The limit setting procedure can be aborted at anytime by

pressing EXIT.

INSTALLING ANTENNA

If the installation requires remote transmitters, an external antenna

is required. Mount the antenna as high as possible for optimal

reception. Do not cut the coaxial cable.

POWERING UP

Connect to power. The controller will go through a startup

sequence displaying the STARTUP SCREEN which indicates the

controller type and firmware version (

Fig. 8

).

After a short delay the MAIN SCREEN will be displayed. If this is

the first time the controller has been used the MAIN SCREEN

should indicate that the limits are not set. If the display shows that

an input is active then rectify the situation before continuing with

the procedure for setting the travel limits for the door (

Fig. 9

).

Note:

Door should be moved manually to half open position.

STEP 1. NAVIGATING TO “SET DOOR TRAVEL MENU”

1.

Press PREV to navigate to the Menu 10 (

Fig. 10

).

2.

Press SET to display MENU 10.1.

3.

Press SET again to enter the limit setting procedure.

STEP 2. SELECTING MOTOR ENCODER MODE

The motor encoder is used to determine motor load and relative

position to the travel limits..

1.

Press OPEN or CLOSE until “On” is displayed.

2.

Press SET to continue (

Fig. 11

).

STEP 3. SELECTING SPEED RAMPING MODE

For speed ramping to be used a Variable Frequency Drive (VFD)

and inverter must be fitted to the opener and the controllers

“FREQ” output used. If speed ramping is required select ‘On’

using the OPEN or CLOSE buttons and then press SET (

Fig. 12

).

n

PRESS

A.T.A

CB14

Firmware

#.##

STARTUP SCREEN

FIG. 8

Limits

Not

Set!

P

Pr

re

es

ss

s

<

<>

>

t

to

o

A

Ac

cc

ce

es

ss

s

M

ME

EN

NU

US

S

MAIN SCREEN

FIG. 9

CAUTION:

CABLES WHICH HAVE A GREEN/YELLOW COLOURED INSULATION ARE FOR

EARTHING PURPOSES ONLY. NEVER USE THESE CABLES FOR ANY OTHER PURPOSE.

Speed

Ramping

Mode

O

PRESS

FIG. 12

n