13 |

A x i o m T o o l G r o u p

6-

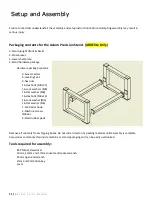

With assistance, the stand can now be flipped over onto the casters and

leveling feet.

7-

Flip the Shelf upside down and stick (1) of the rubber pads on each corner

of the shelf flange.

a.

Install shelf between the braces on the stand, all the way towards

the rear.

b.

The small rubber pads should now be between the flange and the

top surface of the brace. This will help prevent unwanted movement

and scratching.

c.

The DSP hook for the controller should be installed on the front right

side of the stand.

Installing the Toolbox:

The toolbox will sit to the front of the stand, so be sure to orient the shelf towards the rear to serve as storage.

d.

Turn the tool-box upside down. Install (1) of each hanger on either side of the toolbox using the installed

threaded inserts and (2) 3mm cap-screw each.

e.

Insert the toolbox into the stand, from the top. The hangers will with snugly between the braces on either

side of the toolbox.

f.

The front can be slid forward to rest within the opening on the stand

upright.

Summary of Contents for AR16 ELITE

Page 1: ...AR8 16 ELITE MANUAL Axiom Tool Group Inc All rights reserved Rev 1 2 2020 ...

Page 46: ...46 A x i o m T o o l G r o u p AR8 Elite Part List ...

Page 47: ...47 A x i o m T o o l G r o u p ...

Page 48: ...48 A x i o m T o o l G r o u p ...

Page 49: ...49 A x i o m T o o l G r o u p ...

Page 50: ...50 A x i o m T o o l G r o u p ...

Page 51: ...51 A x i o m T o o l G r o u p ...

Page 52: ...52 A x i o m T o o l G r o u p ...

Page 53: ...53 A x i o m T o o l G r o u p ...

Page 54: ...54 A x i o m T o o l G r o u p ...

Page 55: ...55 A x i o m T o o l G r o u p AR16 Elite Part List ...

Page 56: ...56 A x i o m T o o l G r o u p ...

Page 57: ...57 A x i o m T o o l G r o u p ...

Page 58: ...58 A x i o m T o o l G r o u p ...

Page 59: ...59 A x i o m T o o l G r o u p ...

Page 60: ...60 A x i o m T o o l G r o u p ...

Page 61: ...61 A x i o m T o o l G r o u p ...

Page 62: ...62 A x i o m T o o l G r o u p ...

Page 63: ...63 A x i o m T o o l G r o u p ...

Page 64: ...64 A x i o m T o o l G r o u p ...