Installation Manual

Page 10 / 16

4.8.

Grounding

4.8.1.

Common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers,

flat washers and the like) is used to attach a listed grounding/bonding device, the

attachment must be made in conformance with the grounding device

manufacturer’s instructions. Details for wiring in accordance with the NEC, and

that the grounding method of the frame of arrays shall comply with the NEC,

article 250

4.8.2.

Common hardware items such as nuts, bolts, star washers, lock washers and the

like have not been evaluated for electrical conductivity or for use as grounding

devices and should be used only for maintaining mechanical connections and

holding electrical grounding devices in the proper position for electrical

conductivity. Such devices, where supplied with the module and evaluated

through the requirements in UL 1703, may be used for grounding connections in

accordance with the instructions provided with the module. All the PV modules

frame and installing support must be earthed correctly in accord to local

electrical laws, use correct ways of grounding, using suitable grounding wires to

connect PV modules and

frame supports. Grounding wires’

materials can be

copper, cooper alloy or other conductors which correspond with electrical laws.

Grounding wires must be connected with earth with suitable grounding

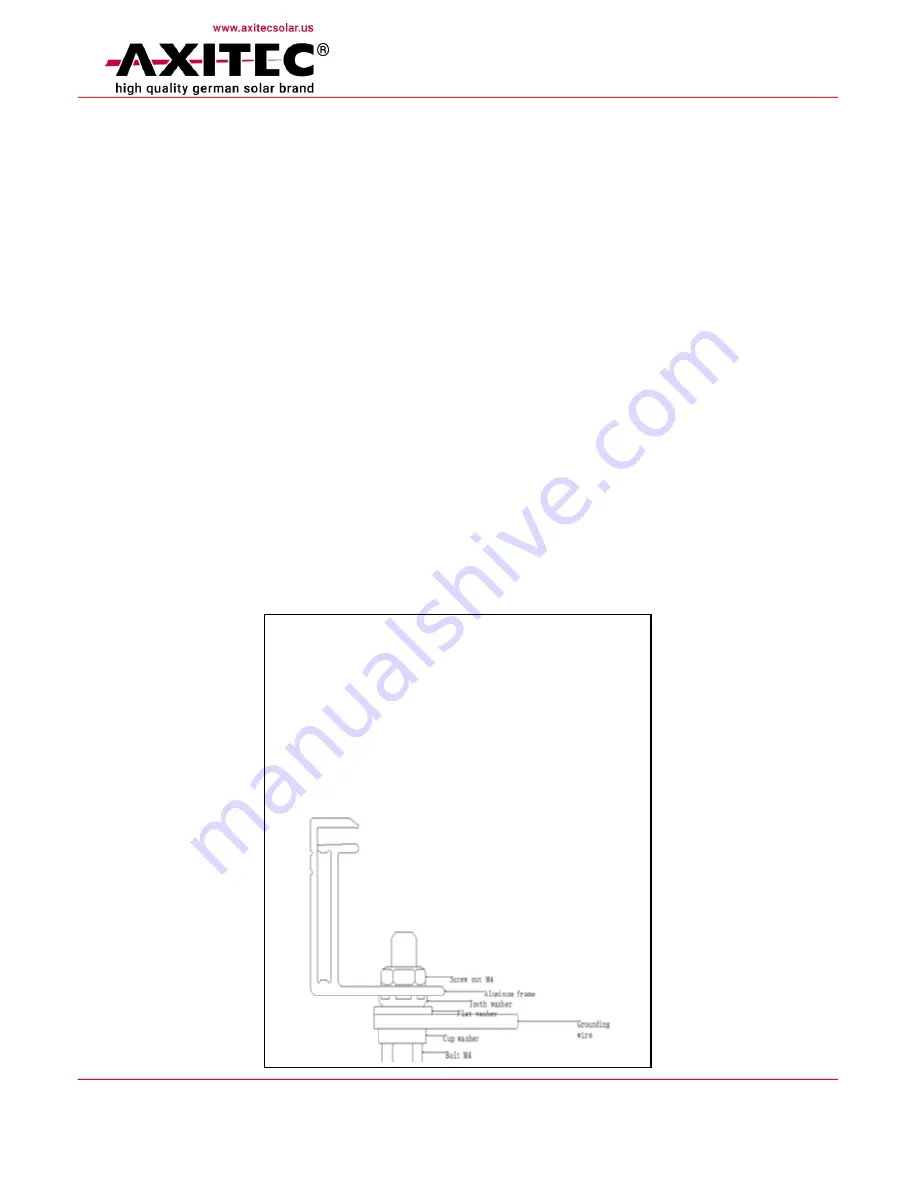

electrode. Use Bolt M4, cup washer, grounding wires, flat washer, tooth washer,

screw nut M4 and install like the photo below, torque should be 2N·M-3N·M, this

way it can be grounded firmly.

Materials and sizes are as follow:

Bolt M4: Stainless steel, abbreviated to SS

cup washer: SS Φ9 Φ4.3 h8

grounding wires: single conductor, the cross section

of conductor is no less than 4mm

2

flat washer: SS Φ9 Φ4.3 h8

tooth washer: SS Φ7.8 Φ4.3 Thickness: 0.5 number of

gears: 11

screw nut M4: SS