Changing the 150mm Grinding Stone

11

11

12

10

8

7

9

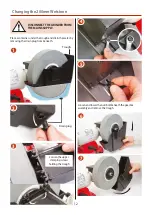

Remove plate flange and carefully remove the stone.

Clean the interior stone guard, inspect the new stone for

cracks and damage to either the front face or the edges

before fitting. Carefully slide the stone on the shaft,

replace the plate flange and the nut then tighten against

the rotation of the stone. DO NOT OVERTIGHTEN.

Tighten the three screws

Rotate the guard cover

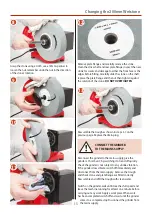

CONNECT THE GRINDER

TO THE MAINS SUPPLY.

CONNECT THE GRINDER

TO THE MAINS SUPPLY.

Reconnect the grinder to the mains supply, give the grinder

a ‘short burst’, by switching it on and off quickly. Check the

grinder is not subject to any undue vibration. If the grinder

does vibrate, switch off immediately and disconnect from

the main supply. Remove the guard cover and check stone

and plate flange are fitted correctly. Check again, if the

grinder is still vibrating the stone/s may need dressing.

Dress the new stone lightly to ensure a ‘good face’ and

good concentricity.

Switch on the grinder, wait until it reaches full speed and

leave the machine running for at least one minute before

carrying out any work. Apply a work piece and check that

the spark guard is correctly positioned and that the tool

rest is securely fixed. Switch off and wait until the grinder

comes to a complete stop.

Summary of Contents for AC200WDG

Page 15: ...Exploded Diagrams Lists 15 ...

Page 18: ...Wiring Diagram 18 ...

Page 19: ...Notes 19 ...