Assembly

8

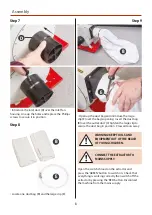

Step 7

• Introduce the inlet duct (D) over the inlet fan

housing. Line up the holes and replace the Phillips

screws to secure it in position.

D

Step 8

• Locate one dust bag (B) and the large clip (E).

B

E

Step 9

• Open up the dust bag and introduce the large

clip (E) over the bag’s opening. Insert the dust bag

(B) over the outlet duct (C) tighten the large clip to

secure the dust bag in position. Clear all tools away.

WARNING! KEEP TOOLS AND

EQUIPMENT OUT OF THE REACH

OF YOUNG CHILDREN.

CONNECT THE EXTRACTOR TO

MAINS SUPPLY.

Open the switch shroud on the extractor and

press the ‘GREEN’ button to switch on. Check that

everything is working correctly then switch off the

extractor by pressing the ‘RED’ button. Disconnect

the machine from the mains supply.

B

E