Changing the Blade

17

3. Clean both blade holders and remove any compacted crud

before fitting a new blade.

4. Check sawblade for flaws (cracks, broken teeth, bending)

before installation.

WARNING! DO NOT USE FAULTY

SAWBLADES.

MAKE SURE THE TEETH ARE

POINTING IN THE CUTTING

DOWN DIRECTION!

5. Lower the pinned blade down through the table insert

hole and into the lower blade holder housing. Insert the blade

between the slot in the holder so that the pins on the end of

the blade engage into the cradle’s recess. Repeat for the

upper blade holder.

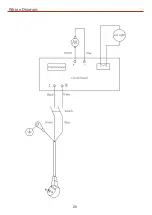

7. Make sure that the pins are seated correctly in both cradles

and nip up both blade holder caphead screws. Replace the

table insert, see fig 28-29 and re-tension the blade as described

on page 12.

Fig 28-29

Insert locating pin

CLEAR AWAY ANY TOOLS

AROUND THE WORK AREA.

CONNECT THE SCROLL SAW

TO THE MAINS SUPPLY!

8. Start the scroll saw and check everything is running correctly.

If all OK, switch off the saw. If not repeat steps 1-7.

Pinless Blades

DISCONNECT THE SCROLL SAW

FROM THE MAINS SUPPLY!

The scroll saw will accept pinless blades, to fit follow the

instruction below.

1. Repeat steps 1-3 on the previous page to remove the

standard pinned blade and clean both blade holders.

2. Locate the two pinless blade clamp holders (J), the supplied

Hex key, (H) and pinless blade (F) see fig 30. Loosen the grub

screws on either side of the holders. Place the blade down into

the machined slots and tighten the screws, securing the blade

in position.

Fig 30

3. Check pinless sawblade (F) for flaws (cracks, broken teeth,

bending) before installation.

NOTE: Make sure both blade clamp holders (J) are the same

way round before fitting the blade, see fig 31.

Fig 31

J

F

H

Continues over...

Table insert

Cutout slot

Grub screws

Machined

slots