Routine Maintenance

28

• Keep the cutter block clean and free from dust build up.

• Check the cutter block regularly for chipped blades and

damage to block i.e cracks in the cutter block.

• When changing the cutter block, remove the cutter

block and place safely away, clean the spindle by

spraying a light coating of oil over the shaft and install

a new cutter block.

WARNING!! DISCONNECT THE MACHINE

FROM THE MAINS BEFORE CONTINUING!

• Opening the access door for the spindle moulder, check

the belt tension. If the belt is loose, using the 16mm socket

spanner loosen the motor bolts and push/pull until the belt

is under tension again, tighten the motor bolts to keep the

tension.

• After several months of constant use the condition of

the chains, sprockets,tension of the drive belts and the

threaded drive shafts of the rise and fall tilt mechanisms

will need to be checked. That may require a service

engineer to oversee the job.

If you find that the machine is not performing as it should

please contact our “Technical Sales Team” by phone on 03332

406406.

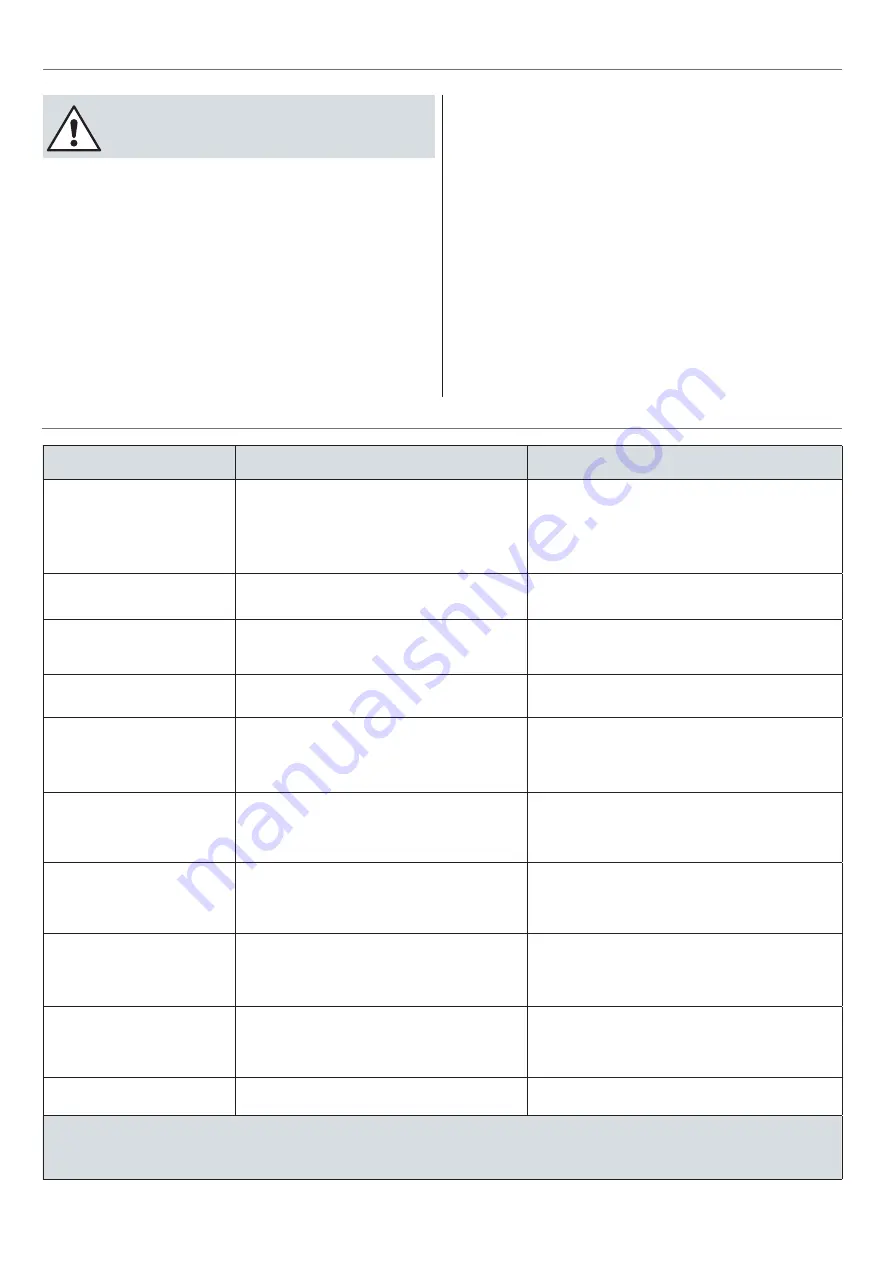

Trouble Shooting Chart

Problem

Cause

Solution

Motor is slow or weak

Voltage from source is low

Windings are burned out or open

Power switch is defective

Circuit is overloaded with appliance, lights or other

electrically power equipment

Check the voltage from your electricity supplier

Have the Motor checked/repaired

Have the power switch replaced

DO NOT use other appliances on the same circuit when

using this machine

Motor overheats

Motor is overloaded

Blunt cutting tool

Check the voltage from your electricity supplier

Replace the cutting tool

When cutting the cutter burns

the work-piece or stalls the

motor

Cutting tool is blunt

Work-piece is warped

Replace the cutting tool

Replace the work-piece

Spindle tilt and height handles

are hard to turn

Tilt locking handle is not fully released

Spindle height handle is not fully released

Release tilt locking handle

Release height locking handle

Spindle moulder vibrates

excessively

Floor surface is uneven

V-belt is damaged

Milling tool is damaged

Loose bolt, screws and nuts

Adjust each leg in turn until machine is level

Replace the V-belt

Replace the cutting tool

Tighten all fixing

Spindle moulder does not start

up

Motor power cord is not plugged in

Circuit fuse is blown

Circuit breaker is tripped

Motor power cord or switch is damaged

Plug in the motor power cord into the socket and switch on

Replace the circuit fuse

Reset the circuit breaker

Have the motor power cord or switch replaced

Power switch does not function

Power switch contacts are burned out

Capacitor is defective

Wiring connections are loose or damaged

Have the power switch replaced

Check the voltage from your electricity supplier

Have the capacitor replaced

Have the wiring connections checked/replaced

Fuses or circuit breakers open

frequently

Motor is overloaded

Fuses or curcit breakers are the wrong size or defective

Blunt cutting tool

Power switch is defective

Feed work-piece more slowly

Replace fuses or circuit breakers

Replace the cutting tool

Have the power switch replaced

Motor stalls, blows fuses or trips

the circuit breakers

Motor is overloaded

Blunt cutting tool

Fuses or circuit breakers are the wrong size or defective

Feeding work-piece too rapidly

Check the voltage from your electricity supplier

Replace the cutting tool

Replace fuses or circuit breakers

Feed the work-piece through more slowly

Spindle moulder is noisy when

in operation

Motor is loose or defective

Have the motor checked or replaced

WARNING! To prevent personal injury or damage to the spindle moulder, maintenance

and other repairs should be carried out by a qualified technician.

(Contact Axminster Tools & Machinery on 0800 371822)