Assembly

8

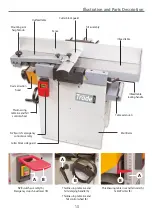

The planer Thicknesser comes 95% assembled. It is

enclosed in a packing case with all the accessories,

see fig 01. Having removed the top and the sides of

the packing case, remove all the components from the machine,

place safely aside.

Fig 01-02

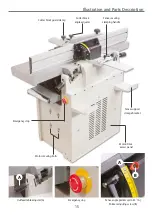

1. Ascertain the orientation of the machine and move it to its

desired position in the workshop. Make sure its positioned on a

flat level surface and ensure that the machine is positioned to

allow sufficient clearance both in front and behind the machine

to cater for the maximum length of timber you will wish to

machine.

Remember sufficient space must be left ‘around’ the

machine to facilitate your stance when overhand

planing and moving from end to end of the machine if you

are thicknessing single handed. Remember that when the

surface tables are up and out of the way’ for thicknessing,

the machine is appreciably wider than when it is in

overhand mode.

2. The machine is secured down on to the pallet that forms

the bottom of the packing case. Remove these ‘hold down’

brackets, see fig 02. Place lifting straps around the machine, DO

NOT under normal circumstances lift, push or pull the machine

using the tables. Any movement is best carried out against the

main frame cabinet. Hoist the machine clear of the pallet, slide

the pallet out of the way and lower the machine in position.

NOTE: There is four 10mm threaded holes to the underside of

main frame, to attach adjustable machine feet if required. Check

our catalogue or vist our website for details.

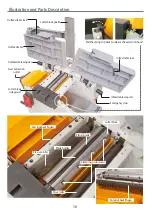

Fig 03-04

3. If you do not have the availability of such a hoist, and are

going to have to ‘manhandle’ the machine off the pallet; make

sure the tables are locked down before applying any lifting

force to them, see fig 03-04.

4. Before adding the fence and the guarding remove the

protective grease film from the unpainted parts of the

machine. Use a proprietary de-greasing agent. Unfortunately,

this cleaning process is always a bit ‘mucky’, you are advised

to wear overalls or coveralls etc., during the process. Keep in

mind the timber you will be machining and its possible

finishing process, when you choose your anti-corrosion agent.

NVR Emergency Stop Lever

Locate the RED emergency stop lever (J) and remove the two

Phillips screws and nuts. Line up the holes in the hinges with

the ones on the NVR switch housing, insert the Phillips screws

through the hinges and replace the nuts. Lightly tighten

sufficiently to allow the lever to move freely, see fig 05-06-07.

Fig 05-06-07

J

Phillips screw/nut

Hold down bracket

Summary of Contents for AT260PT

Page 4: ...What s Included 4 C D F E G H I ...

Page 5: ...What s Included 5 L N K J M Continues Over ...

Page 34: ...Exploded Diagrams Lists 34 DIAGRAM A AT260PT AT260SPT PlanerThicknesser ...

Page 36: ...Exploded Diagrams Lists 36 AT260PT AT260SPT PlanerThicknesser DIAGRAM B ...

Page 38: ...Exploded Diagrams Lists 38 AT260PT AT260SPT PlanerThicknesser DIAGRAM C ...

Page 40: ...Exploded Diagrams Lists 40 AT260PT AT260SPT PlanerThicknesser DIAGRAM D ...

Page 42: ...Exploded Diagrams Lists 42 AT260PT AT260SPT PlanerThicknesser DIAGRAM E ...

Page 46: ...Exploded Diagrams Lists 46 DIAGRAM A AT310SPT PlanerThicknesser ...

Page 48: ...Exploded Diagrams Lists 48 DIAGRAM B AT310SPT PlanerThicknesser ...

Page 50: ...Exploded Diagrams Lists 50 DIAGRAM C AT310SPT PlanerThicknesser ...

Page 52: ...Exploded Diagrams Lists 52 DIAGRAM D AT310SPT PlanerThicknesser ...

Page 54: ...Exploded Diagrams Lists 54 DIAGRAM E AT310SPT PlanerThicknesser ...

Page 58: ...Spiral Cutter Block Diagram 58 Spiral Cutter Block 10 Inch Spiral Cutter Block 12 Inch ...

Page 59: ...Wiring Diagrams 59 AT260PT AT260SPT DIAGRAM AT310SPT DIAGRAM ...