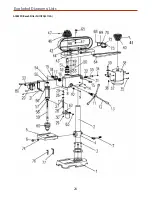

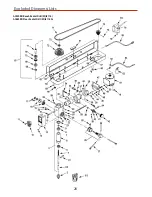

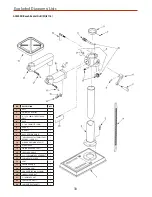

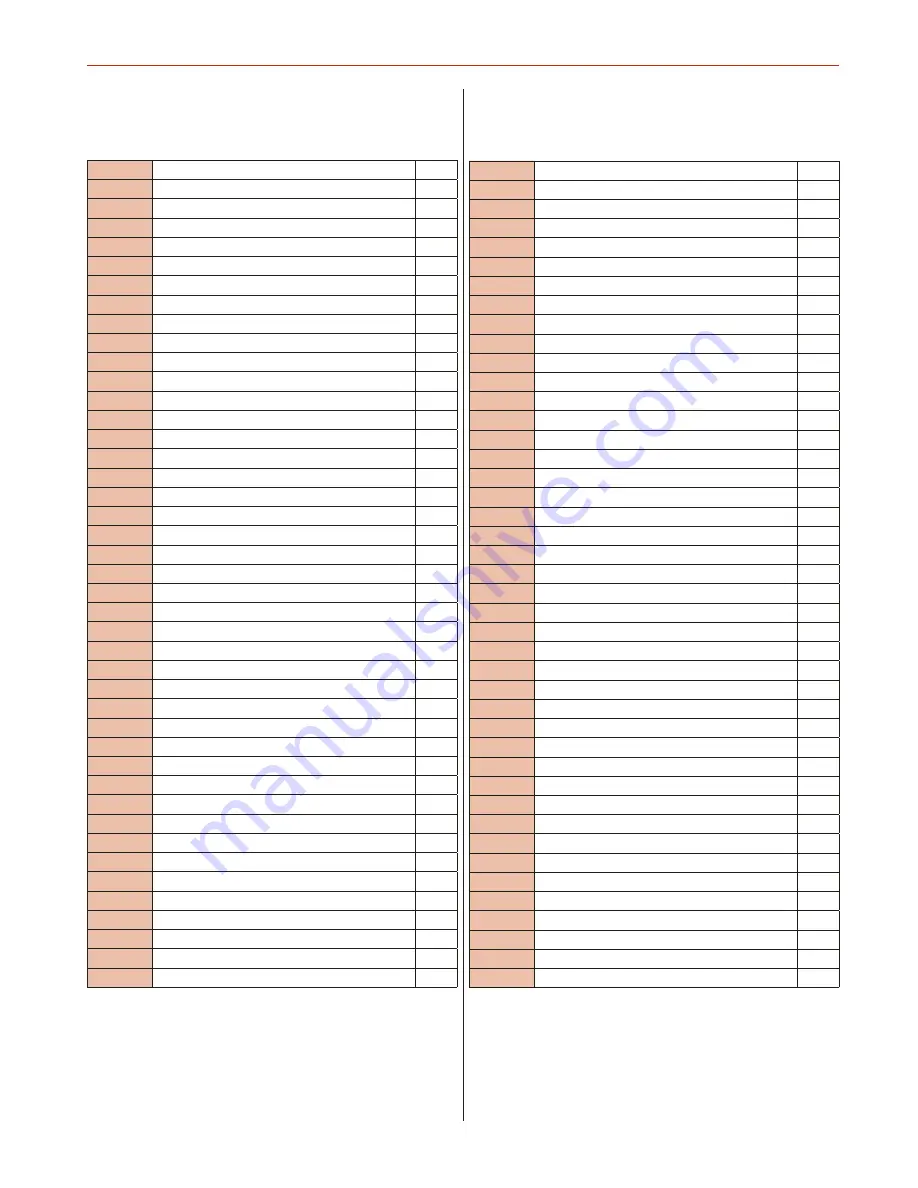

Exploded Diagrams/Lists

29

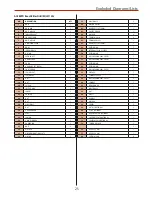

NO

DESCRIPTION

QTY

2

CHUCK

1

3

LOWER SPINDLE ASSEMBLY

1

4

SPINDLE

1

5

6202LL BALL BEARING

1

6

QUILL

1

7

6201LL BALL BEARING

1

8

RETAINING RING

1

9

RUBBER BUMPER

1

10

SWITCH

1

11

THREADFORMING SCREW

2

13

PAN HEAD SCREW

4

14

COVER

1

15

PAN HEAD SCREW

3

16

5MM SERRATED WASHER

2

17

HEX NUT

2

18

CAP COVER AND SPRING

1

19

HEX NUT

5

20

CONE POINT SET SCREW

1

21

DRILL PRESS HEAD

1

22

POINTER

1

23

RIVET

1

24

SPRING PIN

1

25

QUILL FEED ASSEMBLY

1

(INCL. REF. NOS. 26 AND 27)

26

KNOB

3

27

HANDLE WITH GRIP

3

28

SPRING PIN

2

29

RADIAL RACK

1

30

RAM

1

31

PAN HEAD SCREW

2

32

SCALE

1

33

LOCKING SHOE

1

34

HANDLE

2

35

HEX NUT

1

36

GUIDE PIN ASSEMBLY

1

37

RAM BRACKET (MODE:ZQJ3116)

1

37

RAM BRACKET (MODE:ZQJ3116A)

1

38

RETAINING RING

1

39

SET SCREW

1

40

GEAR

1

41

SPACER

2

42

KNOB

1

43

BRACKET

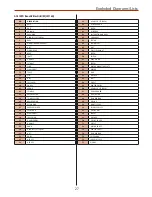

1

44

TENSION ADJUSTMENT BAR

2

45

HEX HEAD BOLT

4

46

8MM FLAT WASHER

4

47

MOTOR MOUNT PLATE

1

48

10MM FLAT WASHER

2

49

10MM LOCK WASHER

2

50

HEX NUT

2

51

MOTOR (INCL. REF. NOS. 52-54)

1

52

CAPACITOR

1

53

STRAIN RELIEF

1

54

MOTOR CORD

1

55

LINE CORD

1

56

STRAIN RELIEF

2

57

6MM FLAT WASHER

4

58

PAN HEAD SCREW

4

59

SET SCREW

3

60

5MM FLAT WASHER

1

61

KNOB

1

62

PULLEY HOUSING

1

63

PAN HEAD SCREW

4

64

CORD CLAMP

4

65

HEX NUT

4

66

GROMMET

1

67

UPPER SPINDLE ASSEMBLY

1

(INCL. REF. NOS. 68-71)

68

RETAINING RING

1

69

6203LL BALL BEARING

2

70

SPACER

1

71

UPPER SPINDLE SLEEVE

1

72

SPINDLE PULLEY

1

73

PULLEY NUT

1

74

V-BELT

1

75

MOTOR PULLEY

1

76

SET SCREW

1

77

CONE POINT SET SCREW

1

78

NUT

1

79

SCREW

1

80

SWITCH

1

81

WEDGE

1

82

LIVE AXLE

1

83

GUARD

1

AC220RD Bench Radial Drill (ZQJ3116)

AC680RD Floor Radial Drill (ZQJ3116A)

Continues Over....

Summary of Contents for 105105

Page 4: ...What s Included 4 1 2 3 4 ...

Page 5: ...What s Included 5 2b 2e 2d 2a 2f 4a 2c ...

Page 6: ...What s Included 6 14 10 5 6 10 9 7 8 13 11 12 ...

Page 24: ...Exploded Diagrams Lists 24 AC285PD Bench Pillar Drill ZQJ4113A ...

Page 26: ...Exploded Diagrams Lists 26 AC315PD Bench Pillar Drill ZQJ4116Q ...

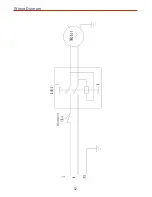

Page 32: ...Wiring Diagram 32 ...

Page 33: ...Notes 33 ...

Page 34: ...Notes 34 ...

Page 35: ...Notes 35 ...