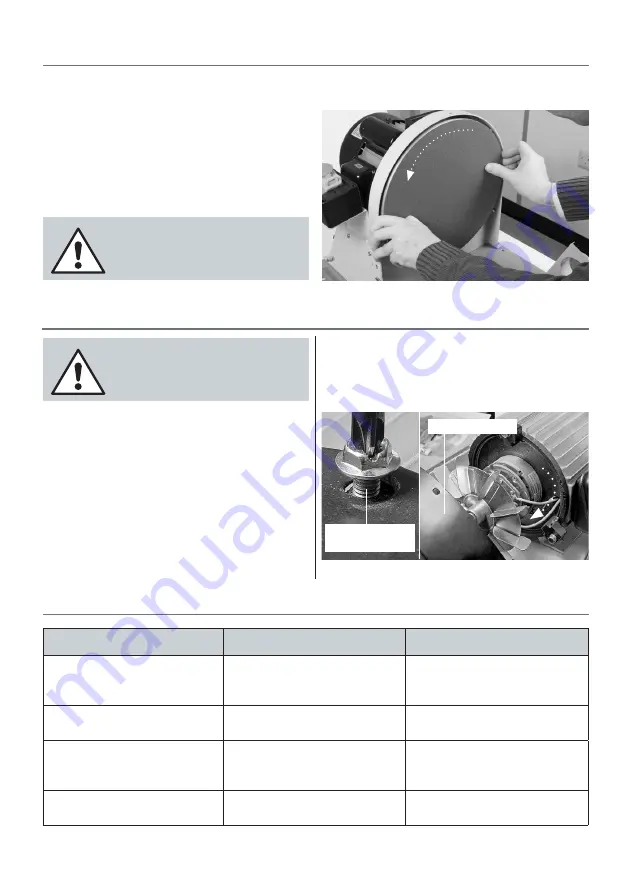

CHANGING THE SANDING DISC

11

DISCONNECT THE SANDER FROM

THE MAINS SUPPLY BEFORE

CONTINUING!

RECONNECT THE SANDER TO THE

MAINS SUPPLY AND CONTINUE

WITH OPERATION.

Fig 16

clean dry cloth. Locate the sanding disc, peel the cover from

the adhesive surface and apply

CAREFULLY

to the disc (see

fig 16). Use a piece of cloth in your hand or wear a glove, to

firmly press the abrasive to the disc, the application will be

reinforced by a gentle sanding action across the face when

you first use the new sanding disc.

Step 7

Re-assemble the sander as described opposite but in

reverse (see figs 10 to 14).

MAINTENANCE

There is very little mechanical maintenance that can be

carried out on the machine. Most prudent maintenance

is preventative and concerned with keeping the machine

clean.

1.

At reasonable intervals, inspect and remove all dust/resin

build ups, and blow the motor clean.

2.

Remove the table assembly and lower the extraction

housing, clean any dust or resin build up. Re-assemble the

sander.

3.

Inspect the sanding disc for signs of wear and tear and

replace if necessarily.

4.

From time to time using a damp cloth wipe over the

sanders surface.

TROUBLESHOOTING

TROUBLE

PROBABLE CAUSE

REMEDY

Motor does not run when power

switch is pressed “ON”

1. Switch is burnt out

2. Connection wire is loose or

damaged

1. Replace the switch

2. Tighten wire or replace

Motor does not run at full speed

1. Power voltage is too low

2. Motor is damaged.

1. Test voltage

2. Check and repair motor

Motor does not reach full power

1. Incorrect power wiring

2. Overloaded

1. Replace with the correct size of

power wiring

2. Reduce load

Motor overheating

1. Motor voltage is different

2. Motor is damaged

1. Check the voltage label

2. Check and repair the motor

Turn the disc while applying pressure

Remove the rear guard and blow the motor clean

Remove the three

Phillips screws

Motor rear guard

Summary of Contents for 107627

Page 12: ...EXPLODED DIAGRAMS LISTS 12 Model DS12DL AP305DS ...

Page 14: ...EXPLODED DIAGRAMS LISTS 14 Model DS12DLMB2 AP305BDS ...

Page 16: ...WIRING DIAGRAM 16 ...

Page 17: ...NOTES 17 ...

Page 18: ...NOTES 18 ...

Page 19: ...NOTES 19 ...