Operating Instructions

15

Remove the

filter cartridge

Testing the Extractor

Reduced Suction Performance

Connect the extraction hose/s to the extractor’s inlet.

After a period of time dust, sawdust and shavings can

build up causing blockages and reduced suction

performance. Carry out the following checks to keep

your extractor working at peak performance.

• Remove the micron filter bag and check for signs of

build up of sawdust and clean with an ‘M’ class vacuum

cleaner.

• If you have the cartridge filter fitted, move the shaker

paddle handle back and forth to remove any built up

dust and debris from inside the filter.

• Check the hose/s for blockages.

• Check the dust collecting bag and empty if full.

• After a period of time remove the cartridge filter if

installed and using a ‘M’ class vacuum cleaner clean the

interior and exterior of the filter.

IF THE EXTRACTOR FAILS TO

START UP OR THERE ARE ANY

OTHER STRANGE NOISES APART

FROM VIBRATION SOUNDS,

CONTACT THE “TECHNICAL SALES”

FOR SUPPORT.

PHONE: 03332 406406

EMAIL:

TECHNICALSUPPORT@AXMINSTERTOOLS.COM

ALWAYS WEAR A DUST MASK AND

EYE PROTECTION.

DISCONNECT THE POWER SUPPLY

FROM THE MAINS!

WAIT UNTIL IT’S UP TO FULL

SPEED AND CHECK FOR SIGNS

OF VIBRATION, IF ALL IS WELL

SWITCH OFF AND WAIT UNTIL

THE EXTRACTOR HAS COME TO

A COMPLETE STOP.

NOTE: ALWAYS TURN ON/OFF THE

EXTRACTOR BY THE NVR CONTROL

SWITCH NOT THE MAINS SWITCH!

CONNECT THE POWER SUPPLY

TO THE MAINS AND SWITCH ON!

WARNING! MAKE SURE CHILDREN

ARE KEPT AWAY FROM THE

EXTRACTOR WHILE IN OPERATION.

NVR ON/OFF

control switch

Summary of Contents for 107696

Page 1: ...AW82E 1 5HP Dust Extractor Code 107696 Original Instructions AT 10 02 2022 BOOK VERSION 3 ...

Page 7: ...Assembly 7 1 4 J O M B 2 3 5 N L C Continues Over Mounting hose for upright support panels C ...

Page 11: ...Assembly 11 30 29 28 26 24 23 I I G 25 G Filter bag belt pocket 27 I H I ...

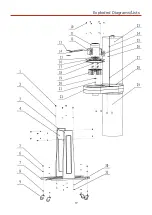

Page 17: ...Exploded Diagrams Lists 17 ...

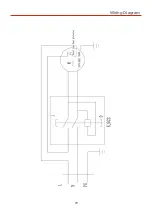

Page 19: ...Wiring Diagram 19 ...