3

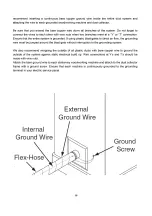

For your own safety, read instruction manual before operating the machine. Learn

the machine’s application and limitations as well as the specific hazards peculiar.

Always wear approved safety glasses or a face shield when operating or observing

machinery to reduce the risk of eye injury or blindness from flying particles everyday.

Eyeglasses are not approved safety glasses.

Dust created while usingmachinery may cause cancer, birth defects, or long-term

respiratory damage. Be aware of dust hazards associated with each workpiece

material, and always wear an approved respirator to reduce your risk.

Always wear hearing protection when operating or observing loud machinery.

Extended exposure to this noise without hearing protection can cause permanent

hearing loss.

Keep hands and clothing away from moving parts. Always tie back or cover long hair.

Wear non-slip footwear to avoid accidental slips which could cause a loss of

workpiece control.

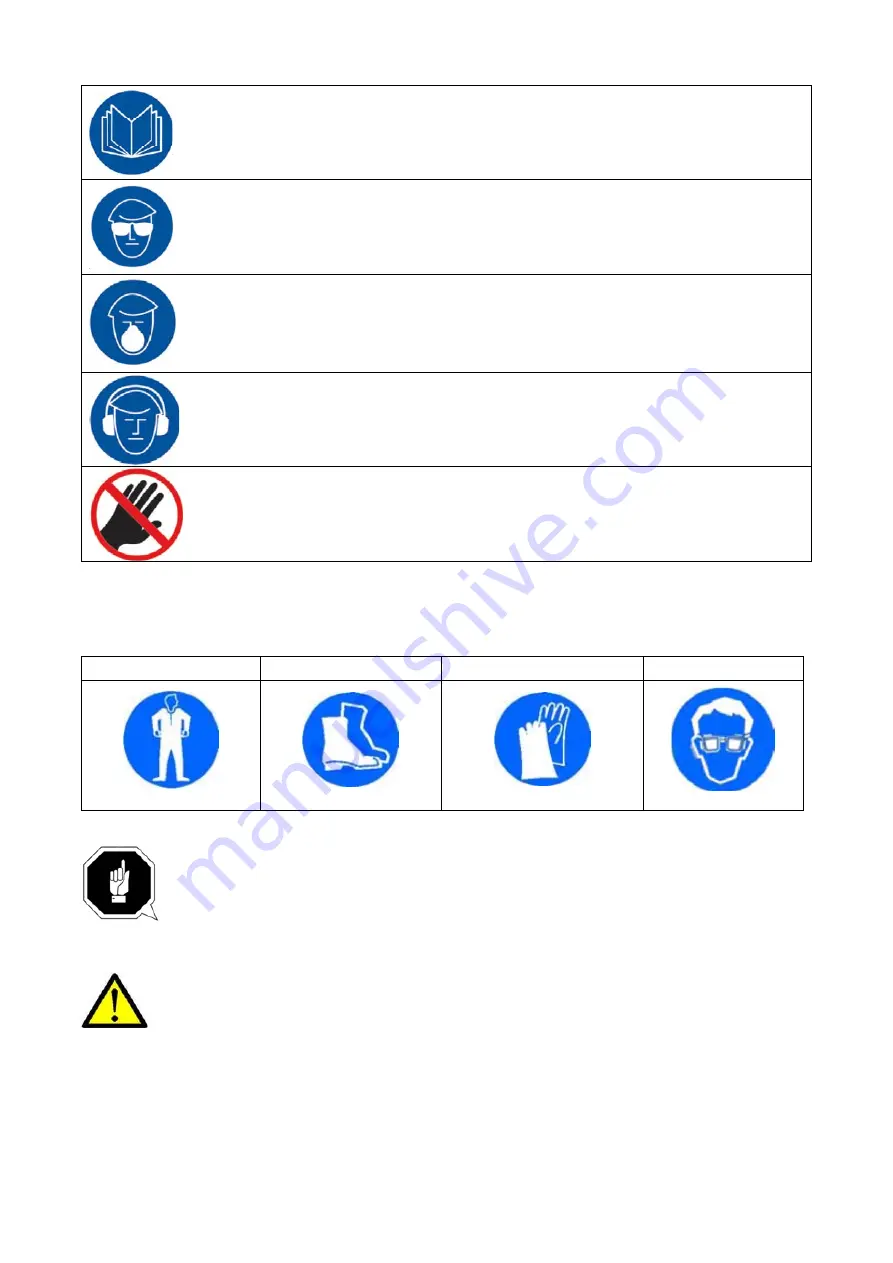

1.11 Personal protective equipment

Dirty or contaminated personal protective equipment can cause illness. Clean your

personal protective equipment after each use and once a week.

1.2 Safety instructions for dust collector

Long-term respiratory damage can occur from using dust collectors without proper

use of a respirator. Fire or explosions can result in smoke inhalation, serious burns,

or death—if machine is used to collect incorrect materials, is operated near

potential explosion sources, or ducting is improperly grounded. Entanglement, amputation, or

death can occur if hair, clothing, or fingers are pulled into the inlet. To reduce the risk of these

hazards, operator and bystanders MUST completely heed the hazards and warnings below.

protective suit

safety shoes

protective gloves

protective glasses

Summary of Contents for 107698

Page 1: ...AW118CE Cyclone Extractor Code 107698 Original Instructions AT 10 02 2022 BOOK VERSION 4 ...

Page 3: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 24: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......