SET UP AND ADJUSTMENT

22

The Riving Knife

1. Raise the saw blade to its highest point and remove the saw

blade crown guard (K) and the table insert, place safely aside,

see fig 71-72.

Fig 71-72

2. Using the spanner loosen the riving knife (H) and check that

the tip of the knife has a clearance of 3-8mm between the

blade. Adjust the four grub screws to the opposite side of the

clamping plate to align the riving knife with the blade. Tighten

the nuts to secure the riving knife in place. NOTE: Check that

the riving knife is parallel to the saw blade by placing the

fence up against them, see fig 73-74.

Fig 73-74

3-8mm

Riving knife (H)

K

Setting the Rip Fence & Scale

MAKESURE THE BLADE IS SQUARE TO THE

TABLE AND THE FENCE IS SQUARE TO THE

BLADE!

1. Remove the crown guard (K) and rip fence extension (F) and

‘T’ bolts and place safely aside. Line up the fence (E) with the

edge of the tables ’T’ slot and press down the locking handle,

see fig 75-76.

2. Check the fence is parallel with the ‘T’ slot, if adjustment is

required loosen the four Hex screws on either side of the fence

assembly and adjust the fence until it’s in line, see fig 77,

re-tighten the Hex screws.

The fence scale does not come pre-mounted to the fence

rail and needs to be stuck in place. NOTE: Before sticking

the scale down make sure the table and fence assembly is

square to the blade. Follow the instruction below.

Fig 75-76

Fig 77

‘T’ Slot

E

Grub screws

H

H

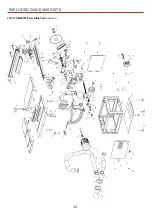

Summary of Contents for 107712

Page 29: ...EXPLODED DIAGRAMS LISTS 29 107712 AW216TS BasicTable Saw Diagram A Continues over ...

Page 31: ...EXPLODED DIAGRAMS LISTS 31 104930 AW216TS Optional SlidingTable Kit Diagram B Continues over ...

Page 34: ...EXPLODED DIAGRAMS LISTS 34 107713 AW254TS BasicTable Saw Diagram A ...

Page 36: ...EXPLODED DIAGRAMS LISTS 36 106805 AW254TS Optional SlidingTable Kit Diagram B ...

Page 39: ...WIRING DIAGRAM 39 ...