Operating Instructions

14

Reposition the belt, making sure the groves in the

belt slot into the groves in the pulleys. Pull/push

the motor assembly until the belt is under tension,

retighten the motor locking handle (a). (See figure

27)

Close the pulley access panel and replace the Hex

screw.

Figure 27

Maintenance

The woodturning lathe has little maintenance, but

it is advised to do the following checks to keep the

lathe in good working order.

After every use

• Clean wood shavings away from the lathe bed and

tool rest

• Smear a light coat of wax (Protec Tool Wax Polish,

Code. 211835) over the lathe bed to allow the Banjo

and Tailstock to run smoothly over the lathe bed and

to prevent corrosion.

Monthly check

• Check the tension of the belt and adjust, see

previous page for changing the belt speed.

• Check any build up of wood shaving on the motor

and spindle pulley’s and clean if necessarily.

• Using a airline, blow out the motor’s air vents.

NOTE: Always use a dust mask and eye protection

NOTE: If the lathe not going to be used for a period of time, smear a light coat of

wax over the lathe bed and place a dust sheet over the lathe.

Wax Points

Summary of Contents for AT1628VS

Page 15: ...Parts Breakdown List 15 Headstock Assembly A...

Page 16: ...Parts Breakdown List 16 Headstock Assembly A...

Page 17: ...Parts Breakdown List 17 Headstock Assembly A...

Page 18: ...Parts Breakdown List 18 Body Assembly B...

Page 19: ...Parts Breakdown List 19 Body Assembly B...

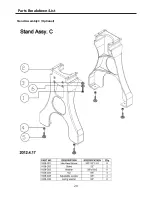

Page 20: ...Parts Breakdown List 20 Stand Assembly C Optional...

Page 21: ...Parts Breakdown List 21...

Page 22: ...Wiring Diagram 22...

Page 23: ...Notes 23...