04

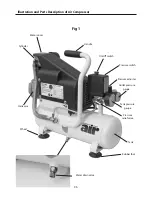

Remove the compressor from the packaging and check

for damage or missing parts. Report any problems to

Axminster Power Tool Centre’s Customer Services

Department. Fit the rubber feet, air filter and quick

release coupling. (see instructions below) Remove the

oil filler plug (See fig 2) and fill with a good quality

compressor oil, (see our catalogue) until the level is in

line with the circle marked on the oil level indicator.

(See page 05) The compressor is now ready for use.

Specification (AWC10HP Air Compressor)

Assembly Instructions

Code

501083

Rating

Light Trade

Power

750W

Free Air Delivered

@40psi - 3.5cfm, @ 90psi - 2.4cfm

Max Pressure

115psi

Noise Level at 3 meters

70dB

Receiver Volume

6 litres

Oil Capacity

100ml

Supply Requirements

230V

Overall L x W x H

515 x 240 x 465mm

Weight

14.5kg

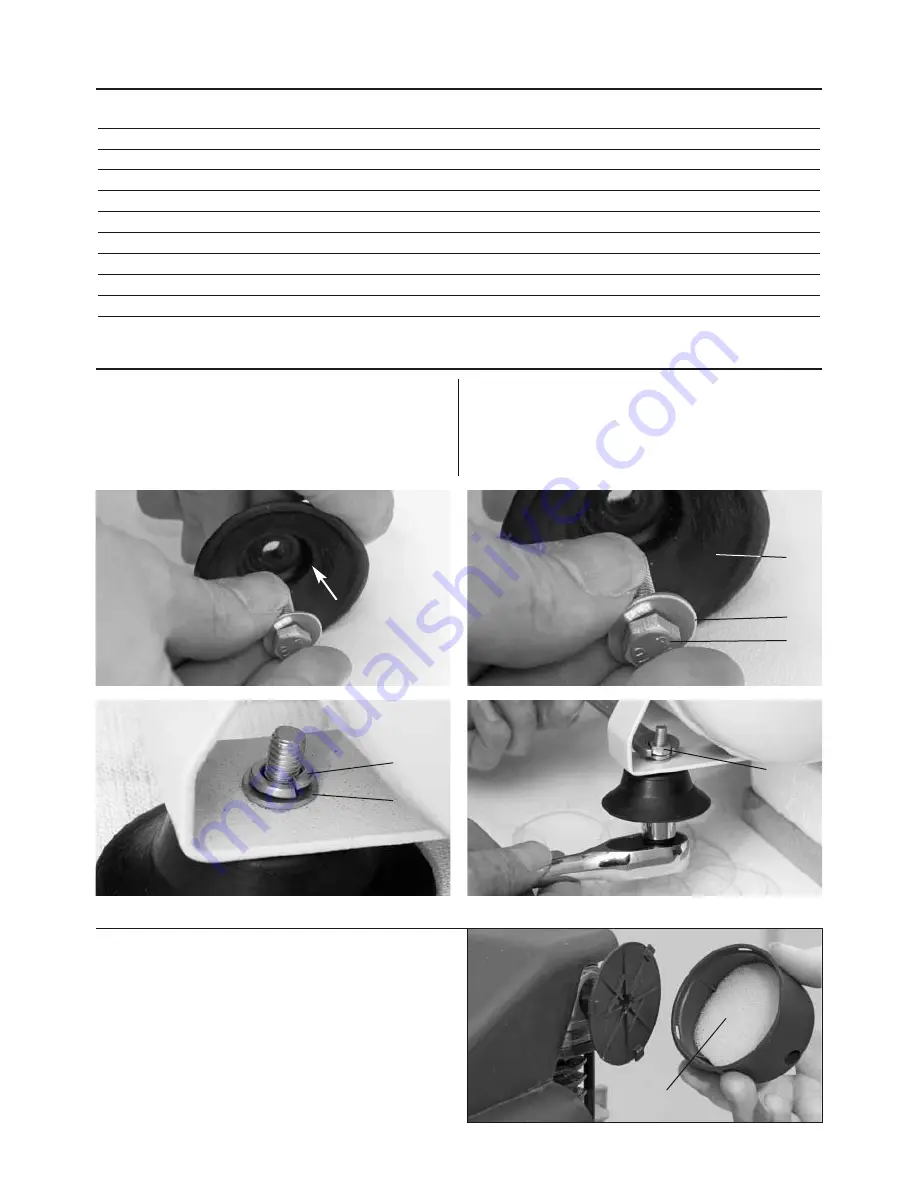

Fitting the wheels

Fitting the air filter

G

D

E

C

A

F

B

Use 10mm spanners to tighten the assembly

Un-clip the filter container, place the filter (G) inside and

reattach the container.

Summary of Contents for AWC10HP

Page 10: ...Parts Breakdown 10 ...

Page 11: ...Parts List Wiring Diagram 11 ...