CORNER DOVETAIL REBATES

18

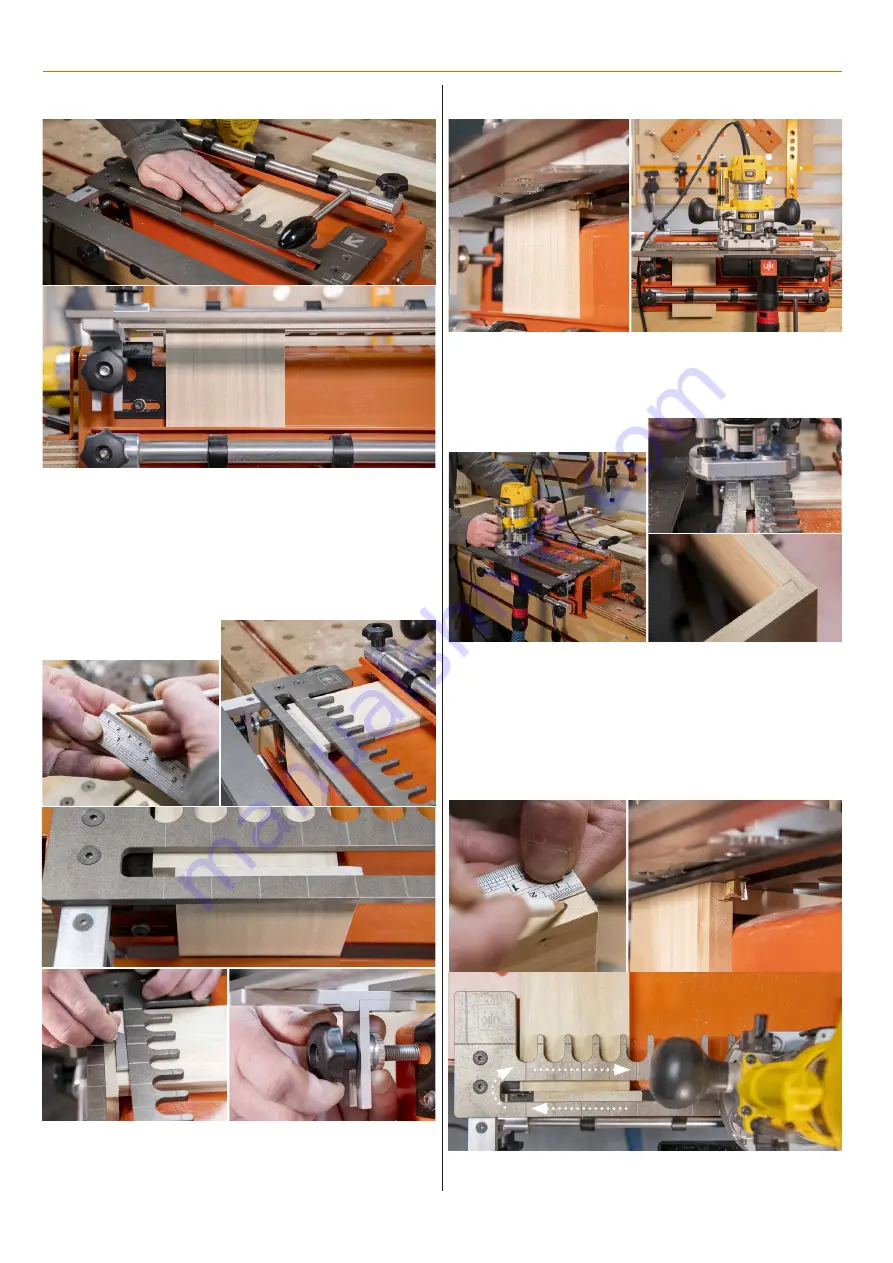

Fig 14-15-16-17-18

Fig 09-10

Fig 03-04

Fig 05-06-07-08

Fig 11-12-13

Single pass 15mm board thickness, 5/8” guide bush -

3)

Mark an 8mm line from the top edge on the side of

the vertical board, see fig 05 then load in the vertical

up against the left hand side stop and up against the

underside of the comb to meet the edge of the

horizontal board, see fig 06-07. Use the wider part of

the magnetic set gauge to ensure that the joint line is

central to the comb slot, see fig 08. Use the comb

adjuster knobs to align & adjust, see fig 08.

4)

Plunge the cutter down through the comb slot so

that the tip of the cutter just meets the marked line,

see fig 09. Attach the magnetic extraction at the right

hand end of the support bar, see fig 10.

5)

Start the cut at the right hand side of the jig

moving the router from right to left in a slow, steady,

continuous motion, see fig 11

DO NOT LIFT THE

ROUTER AT ANY TIME DURING A CUT

, see fig 12-13.

The process to achieve a good corner edge alignment on

a 15mm board is as previously described in steps 1 to 5

apart from the use of the ⅝”(15.9mm) guide bush & the

direction of travel with the router, 14-15-16-17-18.

Direction of travel -

clockwise