Project rev.

Sheet rev.

Drawing by

Date

Modified by

Description

A

B

C

D

E

F

1

2

3

4

5

6

7

8

Date of modification

Sheet

Loc

HL

/

Project ID

Boat

Boat model

Product code

Copyright by

Sub-product code

Title

1

2

3

4

5

6

7

8

A

B

C

D

E

F

58

22

Axopar

A1: INTRODUCED DRAWING.

TuM

9.6.2020

TuM

1

A

9.6.2020

18

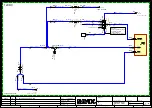

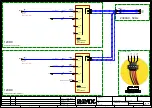

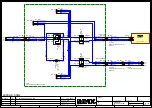

DIAGRAM -

NAVIGATION EQ.

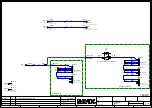

1

2

23804

-F

.4

3A

AIC: 2500A

PLOTTER 1

1

-F4

2

-F4

MA

1

2

23804

-F

.5

3A

AIC: 2500A

PLOTTER 2

1

-F5

2

-F5

INPUT+

4/8

2635810

-BS_X2b

5/8

2635810

-BS_X2b

1

2

23804

-F

.6-

3A

AIC: 2500A

PLOTTER 1

1

-F6-

2

-F6-

MA

4/8

2635810

-EX_X2b

1

2

23804

-F

.7-

3A

AIC: 2500A

PLOTTER 2

1

-F7-

2

-F7-

INPUT+

5/8

2635810

-EX_X2b

4/8

2634810

-X.2b

5/8

2634810

-X.2b

-A.1

PLOTTER 1

Power: 30W

+/2

-A1

-/2

-A1

-A.2

PLOTTER 2

Power: 30W

+/2

-A2

-/2

-A2

-XG:1b

15318

DECK H. INPUT-

1/1

KR5

-XG1b-1

EXTENDED PACKAGE

EXTENDED PACKAGE

BASIC PACKAGE

BASIC PACKAGE

CONSOLE AREA

CONSOLE AREA

12VDC

2.5 RED

PL

2.5 RED

PL

2.5 RED

PL

2.5 RED

PL

2.5 RED

PLOTTER_1

2.5 RED

PLOTTER_2

2.5 BLACK

INPUT-

2.5 BLACK

INPUT-

6 RED

6 RED

Summary of Contents for 22 SPYDER

Page 1: ...OWNER S MANUAL AXOPAR 22 SPYDER ...

Page 59: ......