2-7

2-3. Air supply

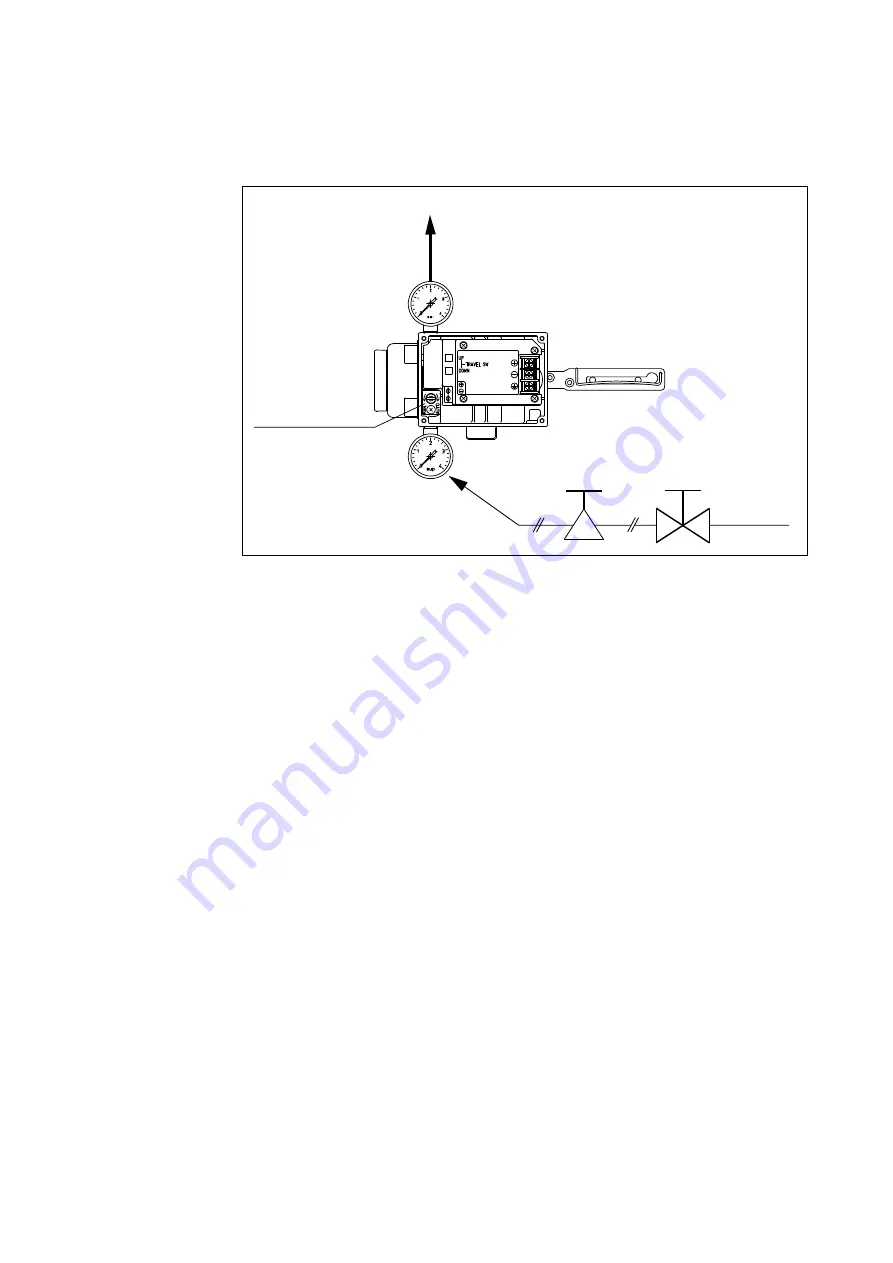

Clean and dry supply air ensures long-term stability of the SVP. A typical air supply system is

shown below:

To actuator

Air output connection

1/4NPT thread

Auto/Manual Switch

Regulator valve

with filter

Shutoff valve

Air supply

Fig. 2-6.

Air supply must be clean; it should not contain foreign substances (moisture, oil, or dust).

The air must be dry, with a dew point at least 10°C lower than the SVP’s lowest site operating

temperature. For example, if the lowest environmental temperature the SVP is exposed to is

0°C, then supply air should not condense at temperatures under -10°C.

A shutoff valve, an air regulator (if not provided with your SVP) and a 3μm or better filter

must be installed between the air supply and the SVP as close as possible to the SVP unit. The

shutoff valve enables disconnection of the SVP from the control valve for ease of maintenance.

Recommended piping practices:

Air supply pipes should have an inside diameter of 6mm (10mm outside diameter tubing

recommended).

Pipes should match the installation environment, i.e. for a corrosive environment, use

vinyl-clad copper pipes.

Use joints that precisely fit the pipes.

Sealing tape is preferable to solid or liquid sealants for pipe joints to SVP air connections.

Prevent sealing tape/sealant from entering pipes.

Use the right length of piping; avoid excess lengths.

Completely flash pipes before use, checking for burrs and other problems.

Check for leaks after installation.

Summary of Contents for 100 Series

Page 1: ...CM2 AVP100 2001 Smart Valve Positioner 100 Series Model AVP100 102 User s Manual ...

Page 12: ...1 4 ...

Page 28: ...2 16 ...

Page 36: ...4 4 4 2 1 Menu Tree ...

Page 75: ......

Page 78: ......

Page 80: ......